MIBI staining

Marc Bosse, Sean Bendall, Mike Angelo

Abstract

This protocol is the standard FFPE tissue staining procedure recommended for Multiplex Ion Beam Imaging Time of Flight instrument (MIBI_TOF) developed in the Sean C. Bendall and Michael R. Angelo labs. The protocol has been successfully used for MIBI and is the result of extensive optimization experiments. It is inspired from state-of-the art of immunohistochemistry staining procedures but differs in some very important steps, namely, glutaraldehyde fixation and final washes prior tissue dehydration. Failure to follow exactly all steps described in this procedure may result in inconsistencies in output data after MIBI_TOF acquisition.

Before start

Verify the stocks of all reagents and place an order or prepare solutions, if some reagents are running low.

Steps

Slide for MIBI

FFPE or frozen sections should be deposited on special conductive slides for MIBI

It is recommended to use freshly cut tissue sections. Otherwise tissue section slides should be stored properly using different state of the art methods (vacuum chamber, nitrogen chamber or vacuum sealed bags)

Slide baking and PT module preparation

Bake the sections at 70°C for 0h 20m 0s in a dry incubator

**Optional** : `1h 0m 0s` ; `1h 0m 0s`

Last 10 min place the slide (s) vertically with the label side up to allow drip down the paraffin

Prepare Target retrieval solution

2.5mL of target retrieval solution 10x (3-in-1), DAKO

in 22.5mL of ultrapure (type 1, >18 MOhms) water

| A | B | C |

|---|---|---|

| Total volume (mL) | Volume (mL) Target retrieval | Volume (mL) H2O |

| 25 | 2.5 | 22.5 |

| 50 | 5 | 45 |

| 100 | 10 | 90 |

Slide deparafination

Insert slides into slide carriers

Place the slide carrier into first xylene container

Press on Menu

Check for Processing time = 30 sec, Lift bar = 976, Number of dips = 3

Continue to press Menu until the screen displays Start at: __

Set Start position corresponding to the first slide carrier position

Exemple: If the first slide carrier is at position 4, use Plus ( + ) or Minus ( -) button to increase or decrease to get Start at: 04

Then press Enter

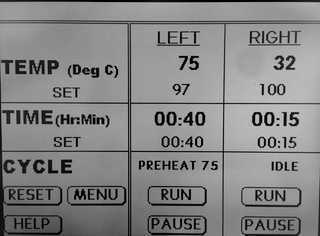

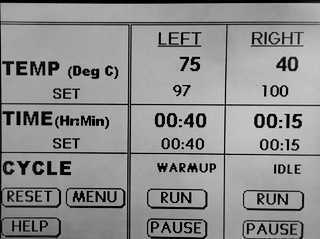

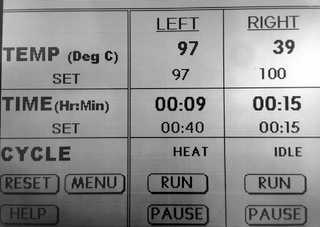

Synchronize when the PT module temperature has reached 75˚C

then Press Run on the Linear Stainer

Allow the rehydration process and wait until the slides have reached the stainless steel tank and stop

Bring the stainless steel tank with the slides in close to the PT module

Antigen Retrieval

Open the PT Module and insert the slides in the warm Target retrieval solution container

Discard water immediately from the stainless steel tank

Verify stock of 1x PBS wash buffer and prepare accordingly if running low

| A | B |

|---|---|

| Reagents | Qty for 1000 mL |

| PBS IHC Wash Buffer with Tween 20 (mL) | 50 |

| Bovine Albumin (BSA), heat shock treated (g) | 1 |

| Ultrapure (type 1) water (mL) | 949 |

Allow to run for 40 min at97°C and then cool down for approximately 50 min and reach 65°C

When the alarm sounds Stop the PT module

Take out the slides and let cool down at room temperature for at least 0h 5m 0s

Prepare two coplin jars filled with MIBI 1x PBS wash buffer

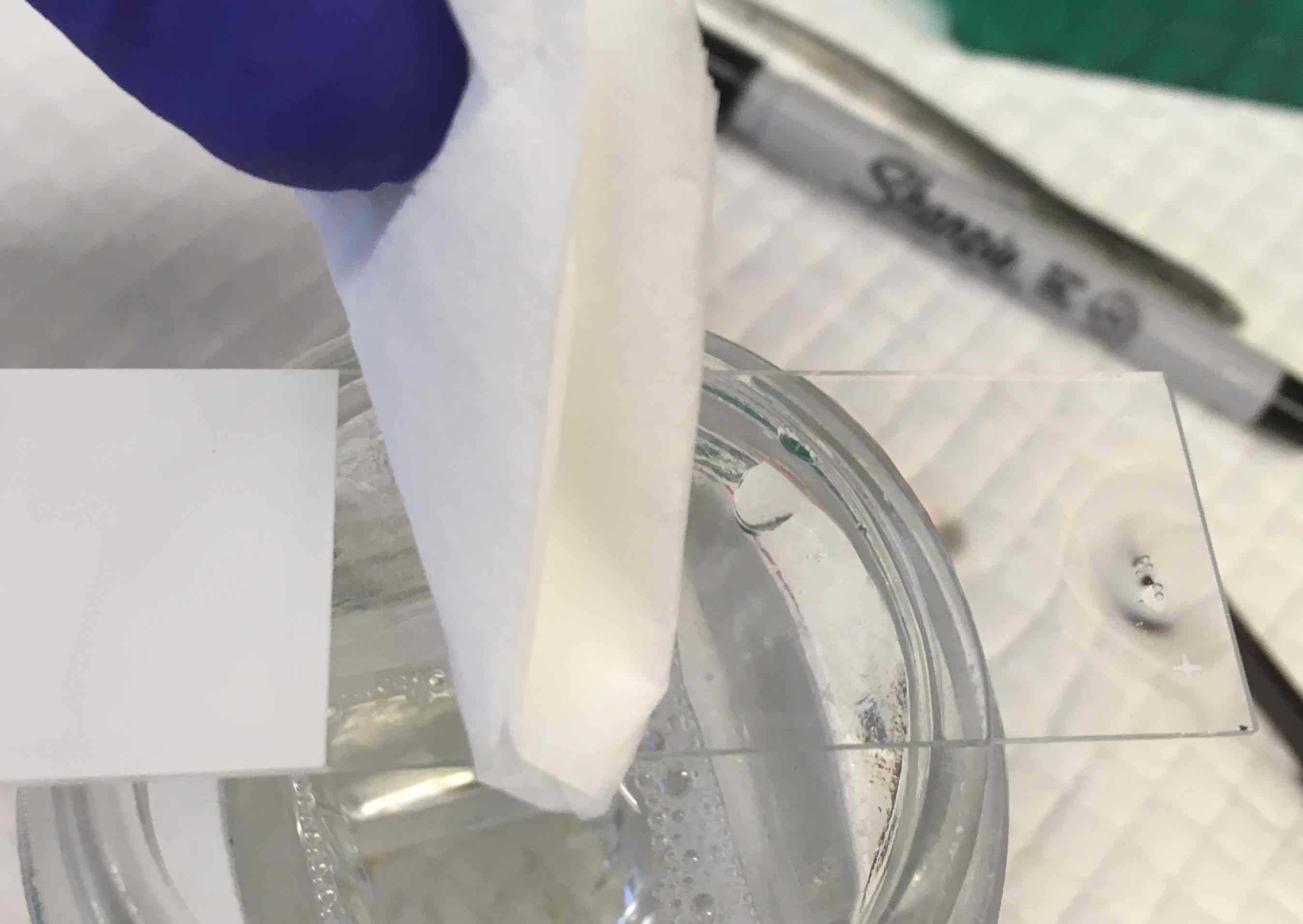

Transfer the slides in the first MIBI 1x PBS wash buffer and use orbital shaker set for 5 min, 70 rpm

Transfer the slides to the second 1x PBS wash buffer and use orbital shaker set for 5 min, 70 rpm

Hydrophobic barrier pen

Optionnal: blocking endegenous biotin

If a biotinylated antibody or a probe is used, it is recommended to block endogenous biotin

Place the slides in the moist chamber

Add drops of Avidin solution (Avidin/Biotin blocking kit, Biolegend) sufficient to cover the sample and incubate for 0h 10m 0s at Room temperature

Wash in coplin jar with MIBI 1x PBS wash buffer and use orbital shaker set for 5 min, 70 rpm

Add drops of Biotin solution sufficient to cover the sample and incubate for 0h 10m 0s at Room temperature

Wash in coplin jar with MIBI 1x PBS wash buffer and use orbital shaker set for 5 min, 70 rpm

Next day, use anti-biotin metal-labeled antibody (clone 1D4-C5) in Stain 2 panel

Blocking

Place the slides in a moist chamber at Room temperature and incubate 0h 20m 0s to 1h 0m 0s

Multiplex Antibody mix

Prepare antibody mix based on the putative multiplex antibody panel

Make sure that all the antibodies are ready to use BEFORE starting to build the panel

It is highly recommended to prepare all the antibodies, ready to use, a day before the panel is built

Evaluate the total volume of multiplex antibody mix by counting the number of slides and the surface area per slide

Refer to the chart for the volume of antibody to apply according to the estimated surface area

| A | B | C | D | E | F |

|---|---|---|---|---|---|

| Estimated Surface area (mm) | 10x10 | 15x15 | 18x18 | 20x20 | 20x45 |

| Volume (µL) | 50 | 70 | 100 | 150 | 350 |

Build an antibody mix table information to make the antibody panel as follow:

Conjugation ID, Target name, Channel, Antibody concentration, Titer, Volume

Exemple:

| A | B | C | D | E | F |

|---|---|---|---|---|---|

| ID | Target | Channel | Concentration µg/mL | Titer (µg/mL) | Volume (µL) |

| 1565 | CD45 | 169 | 50 | 0.25 | = |

| 1516 | CD8 | 158 | 50 | 0.5 | = |

| ... | ... | ... | ... | ... | ... |

| Total | 500 | ||||

| Antibody mix | =F5-F7 | ||||

| Antibody diluent (NHS 3%) | =F5-SUM(F2,F3) |

For Antibody Diluent (NHS 3%) solution preparation refer to MIBI and IHC solutions protocols

Add 400µL of antibody diluent (NHS 3%) to a Centrifugal 0.1 µm filter unit (Millipore, UFC30VV00)

10000rcf

Discard flow through

Add antibody mix to the filter unit

10000rcf

Stain 1 (Overnight)

Remove the blocking solution by tapping the slide on a side

Immediately add the filtered multiplex antibody mix

Place the moist chamber at 4˚C , preferably in a place with low disturbance (e.g. a designated area in a cold room)

Wash buffer

Prepare two Coplin jars filled with 1x PBS wash buffer

Transfer the slides into the first Coplin jar and use orbital shaker set for 5 min, 70 rpm

Transfer the slides into the second Coplin jar and use orbital shaker set for 5 min, 70 rpm

Stain 2 (1h)

Add adequate volume of the selected sub-panel of antibody mix

Refer to the chart for the volume of antibody to apply

| A | B | C | D | E | F |

|---|---|---|---|---|---|

| Estimated Surface area (mm) | 10x10 | 15x15 | 18x18 | 20x20 | 20x45 |

| Volume (µL) | 50 | 70 | 100 | 150 | 350 |

| Estimated # of drops | 1 | 2 | 3 | 4 | 8-9 |

Place sample in a sealed humidity chamber, transfer to 4oC refrigerator, and incubate 1h 0m 0s

After 1h incubation

than go to step 33

Prepare solutions

Prepare fresh glutaraldehyde fixing solution

Glutaraldehyde fixing solution

- Add

30mLof 1x PBS low barium in a 50 mL tube - Break the glass glutaraldehyde 8% (amber vial)

- Add the content of the glutaraldehyde (10 mL) by inverting it and tapping the bottom of the vial in the 50 mL tube

- Transfer the content in a linear stainer container

Set the linear stainer containers

Fill containers with the following solution and order

Glutaraldehyde x 1, PBS low barium x 1, TRIS 100 mm pH 8.5 x 3, ddH2O x 2, 70% Ethanol x1, 80% Ethanol x1, 95% Ethanol x 2, 100% Ethanol x 2, exit stainless steel tank = empty

Glutaraldehyde fixation

Mount the slides on the linear slide holder

Fix for 0h 5m 0s

Rinse briefly with 1x PBS low barium

Dehydration and Storage

Press on Menu

Check for Processing time = 30 sec, Lift bar = 976, Number of dips = 3

Continue to press Menu until the screen displays Start at: __

Set Start position corresponding to the first slide carrier position

Exemple: If the first slide carrier is at position 3, use Plus ( + ) or Minus ( -) button to increase or decrease to get Start at: 03

Then press Enter

Press Run on the Linear Stainer

Allow the dehydration process and wait until the slides reached the empty stainless steel tank and stop

Store the slides immediately under vacuum until MIBI acquisition

Alternatively, the stained slides can be stored in a vacuum sealed bag for longterm storage pre and post MIBI acquisition