Photolithography for microfluidics

Nadanai Laohakunakorn

Abstract

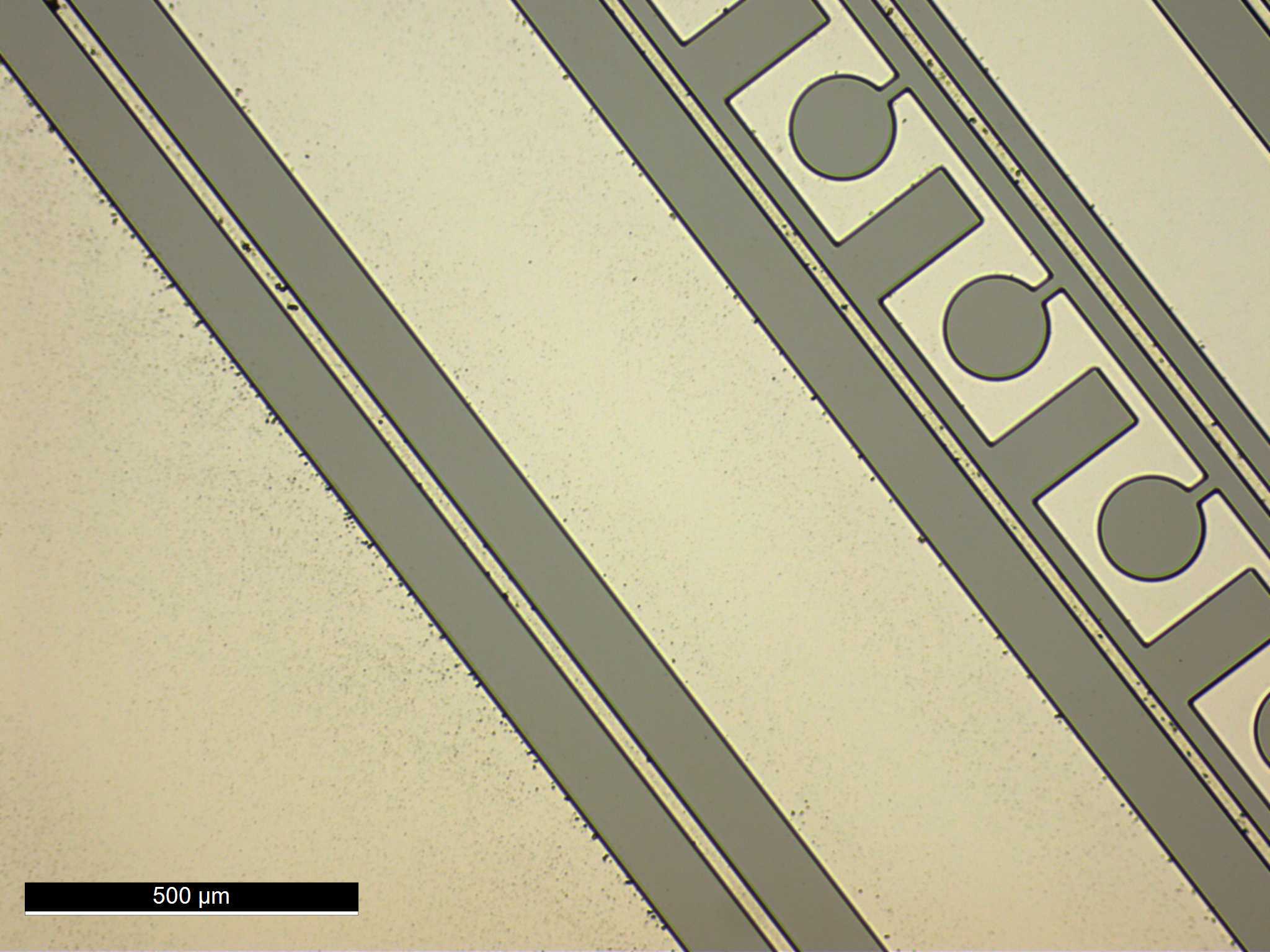

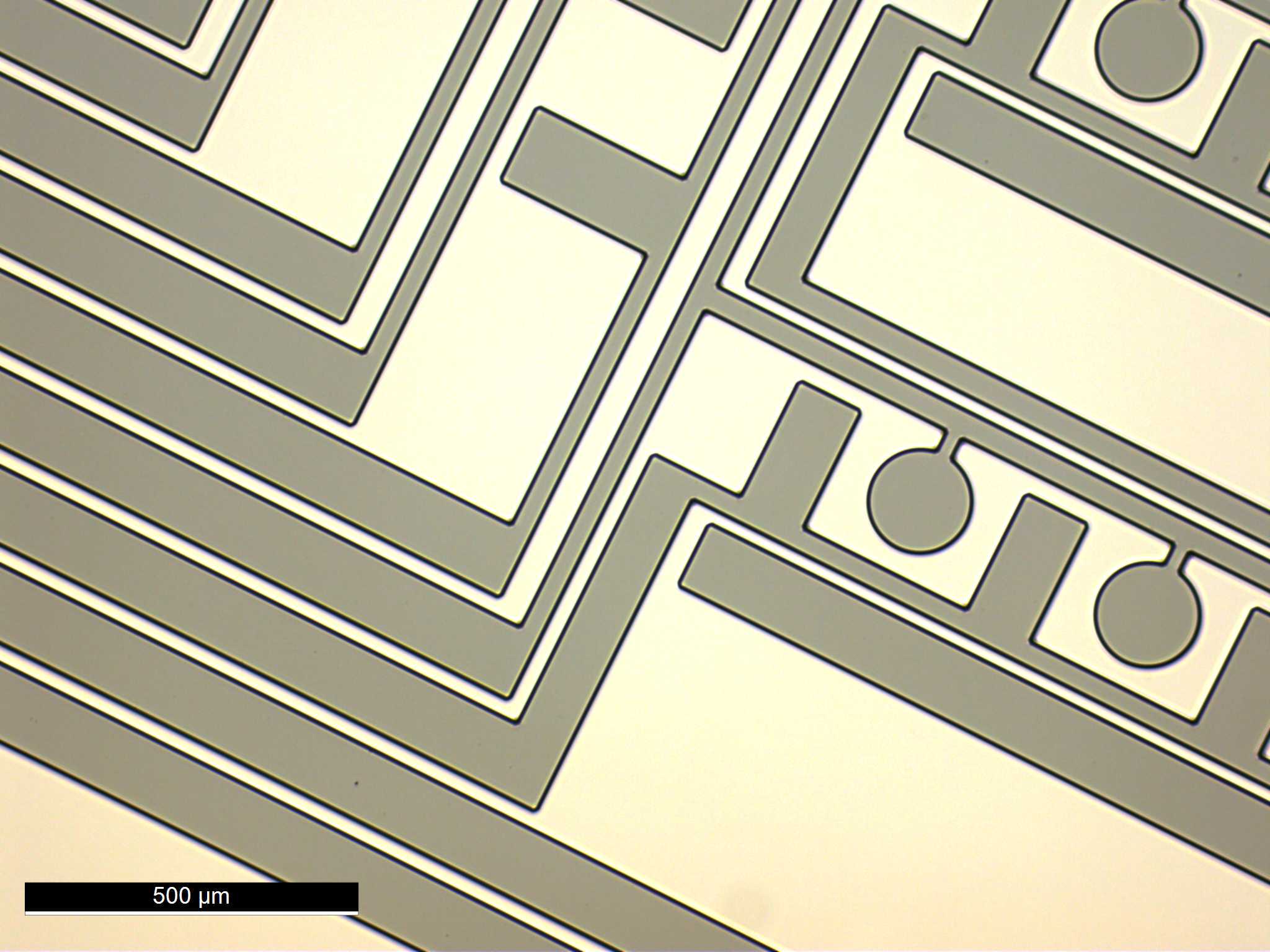

Photolithography for microfluidic mold fabrication, successfully tested at the Scottish Microelectronics Centre. Produces rounded flow layer using positive resist SPR 220-7 with ~12um features, and rectangular control layer using negative resist SU-8-3035 with ~35um features).

Adapted from dx.doi.org/10.17504/protocols.io.46wgzfe / Laohakunakorn et al. 2021 (https://doi.org/10.1007/978-1-0716-1032-9_9).

Steps

Flow Layer

HMDS priming

Prime a clean Si wafer in a sealed box with HMDS for 0h 10m 0s

Prebake

Transfer to hotplate and carry out pre-bake at 120°C for 0h 12m 0s.

Spin coat with SPR 220-7 (Megaposit) SPR_220_DATA_SHEET_RH.pdf

Transfer wafer to spin coater and run following programme using SPR 220-7 resist:

-

400rpm -

1000rpm

at 200 rpm/s. This coats the wafer with ~12 um.

Softbake

Transfer to hotplate and carry out soft-bake at 105°C for 0h 6m 0s . Remove promptly when done.

Exposure

Expose with the following settings (for a Karl Suss MA8 mask aligner):

Multiple exposure steps: [ 0h 1m 20s exposure + 0h 0m 10s wait] x 2 cycles, for a total of 160s (=638mJ/cm^2)

WEC=cont

Expose type = prox

40um alignment gap

5um expose gap

WEC offset OFF

N2 purge NO

The Karl Suss machine has a flux of 3.99 mW/cm^2 as measured from last maintenance. We would like an exposure of 660 mJ/cm^2.

Wait: leave the wafer in a sealed wafer box for 2h 0m 0s.

Post-exposure bake

Transfer to a hotplate and hold at 110°C for 0h 5m 0s

Wait: leave the wafer in a sealed wafer box for 0h 45m 0s

Develop with MF26A

Develop right side up for up to 0h 5m 0s, rinse with DI water, and dry gently with compressed N2.

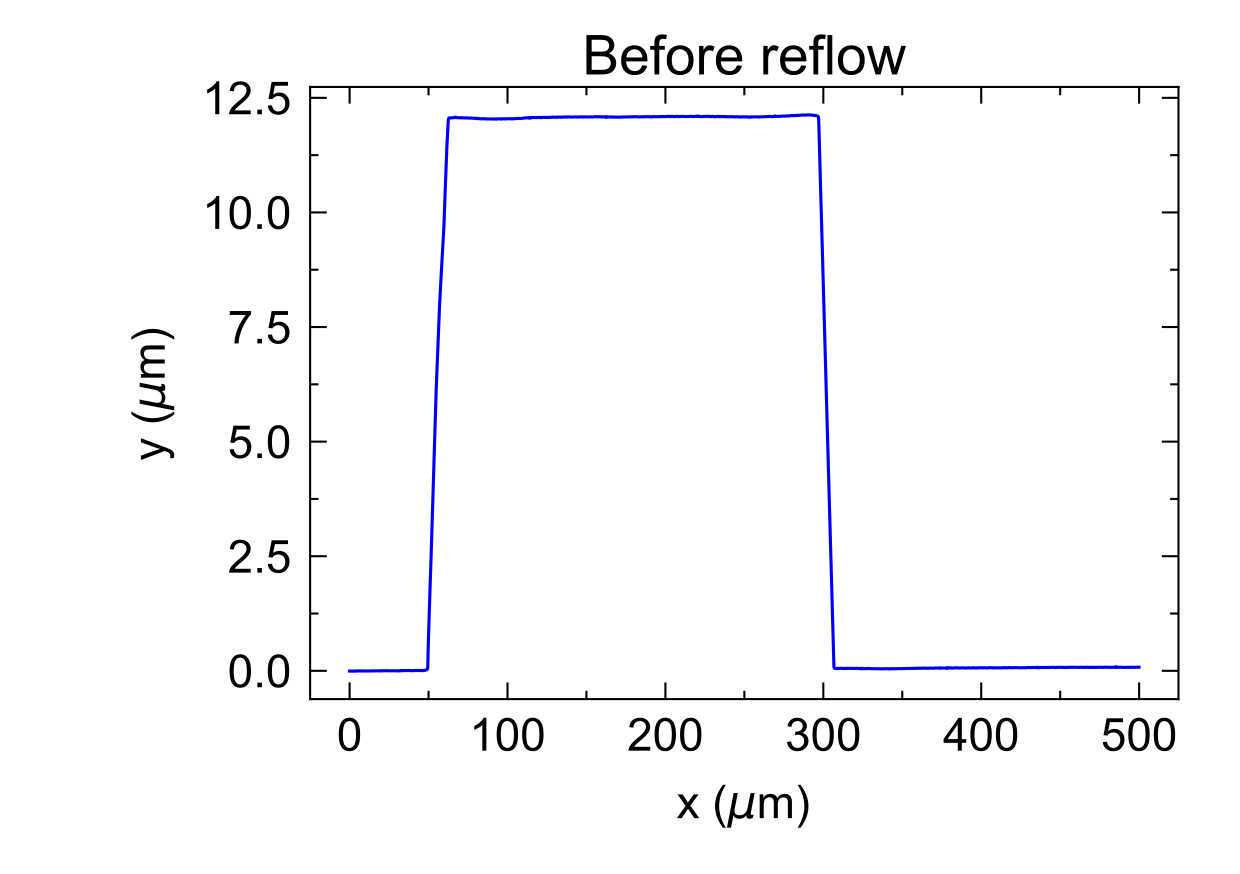

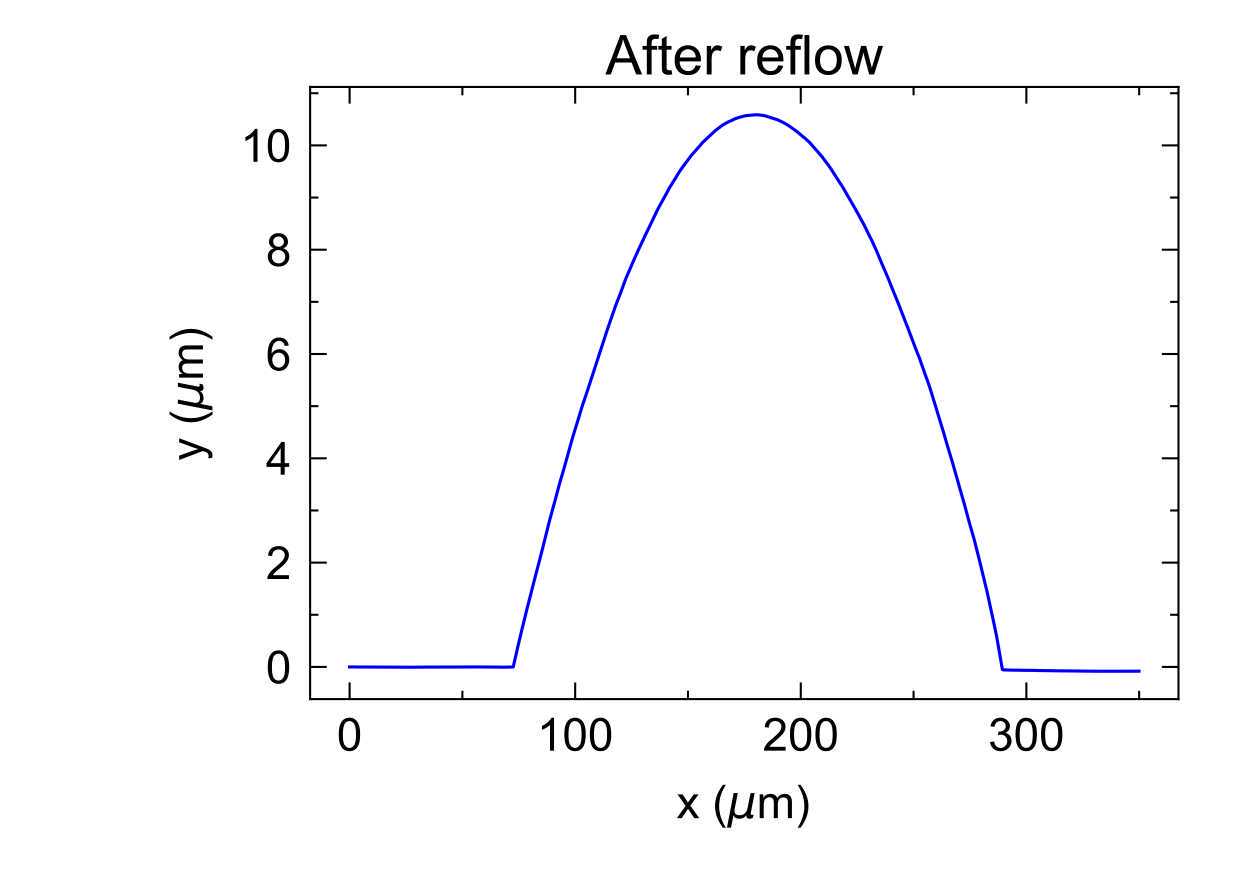

Reflow

Control layer

O2 plasma treatment

Treat with O2 plasma for 10 minutes in barrel asher. (At SMC, Electrotech 508 with typical parameters: forward power 350W, flow 32%, pressure 0.8 torr)

Spin coat with SU-8-3035 (Kayaku) KAM-SU-8-3000-Datasheet-7.10-final.pdf

Spin coat with SU8-3035 using the following programme with ramp rate of 100rpm/s for all steps:

-

500rpm -

3000rpm= 25s ramp + 40s hold -

4000rpm -

3000rpm -

0rpm

Make sure the spin coater has a plastic liner installed. If necessary clean back and edge of wafer with wipe soaked in PGMEA.

Softbake

Place on hotplate for 0h 12m 30s at 95°C

Let wafer come to room temp (few mins) before exposure. If there are wrinkles, place on hotplate until wrinkles disappear.

Exposure

Expose with the following settings (for a Karl Suss MA8 mask aligner):

Multiple exposure steps: [ 0h 0m 18s exposure + 0h 0m 10s wait] x 5 cycles, for a total of 90s (=359mJ/cm^2)

WEC=cont

Expose type = soft

30um alignment gap

5um expose gap

WEC offset OFF

N2 purge NO

Post-exposure bake

a. Place on hotplate at 65°C for 0h 1m 0s .

b. Move to second hotplate and hold at 95°C for 0h 4m 0s .

Wait for a minimum of 0h 10m 0s .

Develop

Rinse with IPA and dry gently with compressed air.

Hardbake

Ramp to 135°C , and hold at 135°C for 2h 0m 0s .

Silanization of wafers

Silanization must be carried out before first use, to prevent PDMS sticking to wafers.

Leave 500µL of chlorotrimethylsilane (Sigma 386529) in an upturned Falcon cap, inside a sealed box with the wafers until the solvent has completely evaporated.