A Comprehensive Guide for Assessing Covalent Inhibition in Enzymatic Assays Illustrated with Kinetic Simulations

Elma Mons, Elma Mons, Sander Roet, Sander Roet, Robbert Q. Kim, Robbert Q. Kim, Monique P. C. Mulder, Monique P. C. Mulder

Abstract

Covalent inhibition has become more accepted in the past two decades, as illustrated by the clinical approval of several irreversible inhibitors designed to covalently modify their target. Elucidation of the structure-activity relationship and potency of such inhibitors requires a detailed kinetic evaluation. Here, we elucidate the relationship between the experimental read-out and the underlying inhibitor binding kinetics. Interactive kinetic simulation scripts are employed to highlight the effects of in vitro enzyme activity assay conditions and inhibitor binding mode, thereby showcasing which assumptions and corrections are crucial. Four stepwise protocols to assess the biochemical potency of (ir)reversible covalent enzyme inhibitors targeting a nucleophilic active site residue are included, with accompanying data analysis tailored to the covalent binding mode. Together, this will serve as a guide to make an educated decision regarding the most suitable method to assess covalent inhibition potency. © 2022 The Authors. Current Protocols published by Wiley Periodicals LLC.

Basic Protocol I : Progress curve analysis of substrate association competition

Basic Data Analysis Protocol 1A : Two-step irreversible covalent inhibition

Basic Data Analysis Protocol 1B : One-step irreversible covalent inhibition

Basic Data Analysis Protocol 1C : Two-step reversible covalent inhibition

Basic Data Analysis Protocol 1D : Two-step irreversible covalent inhibition with substrate depletion

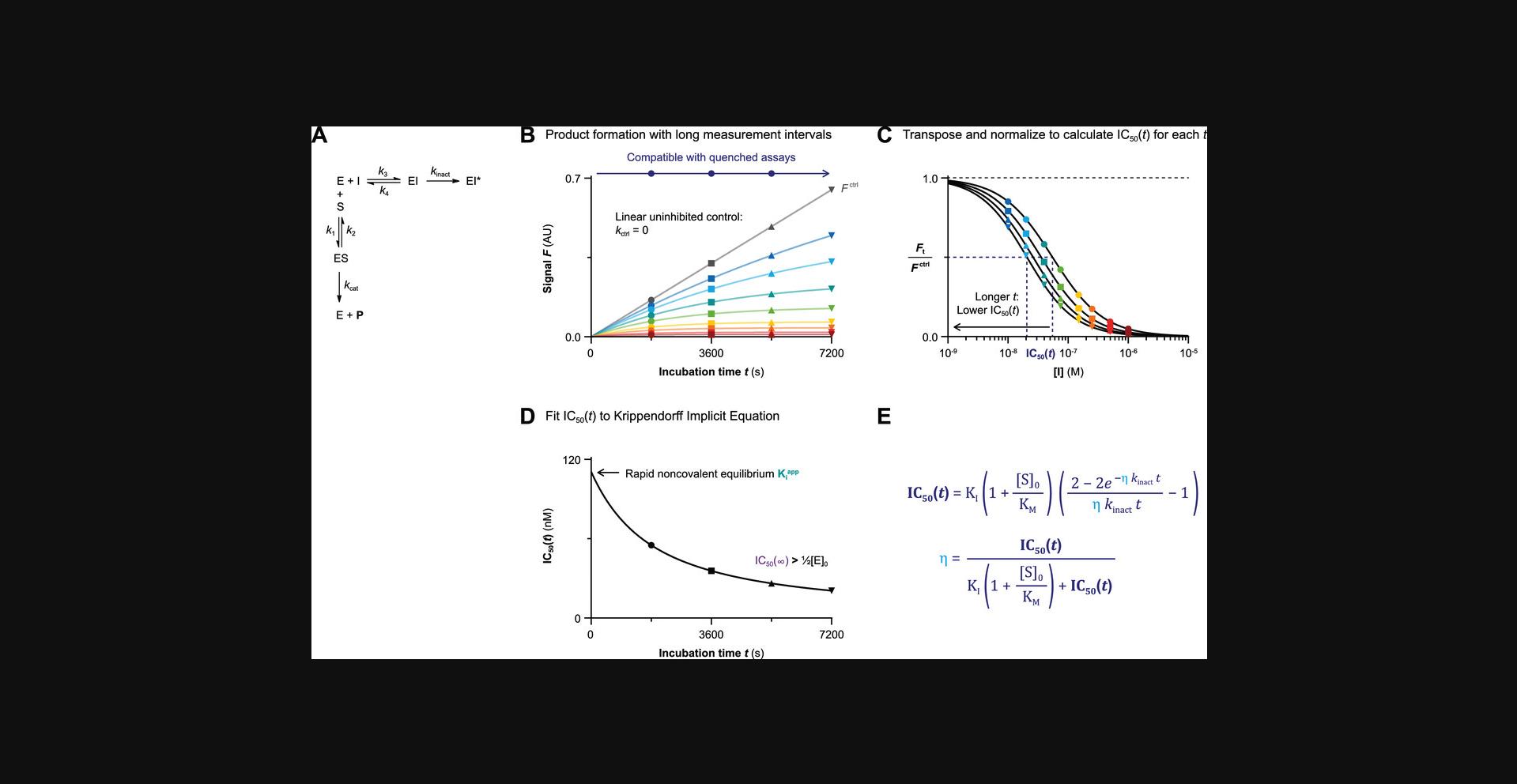

Basic Protocol II : Incubation time–dependent potency IC50(t)

Basic Data Analysis Protocol 2 : Two-step irreversible covalent inhibition

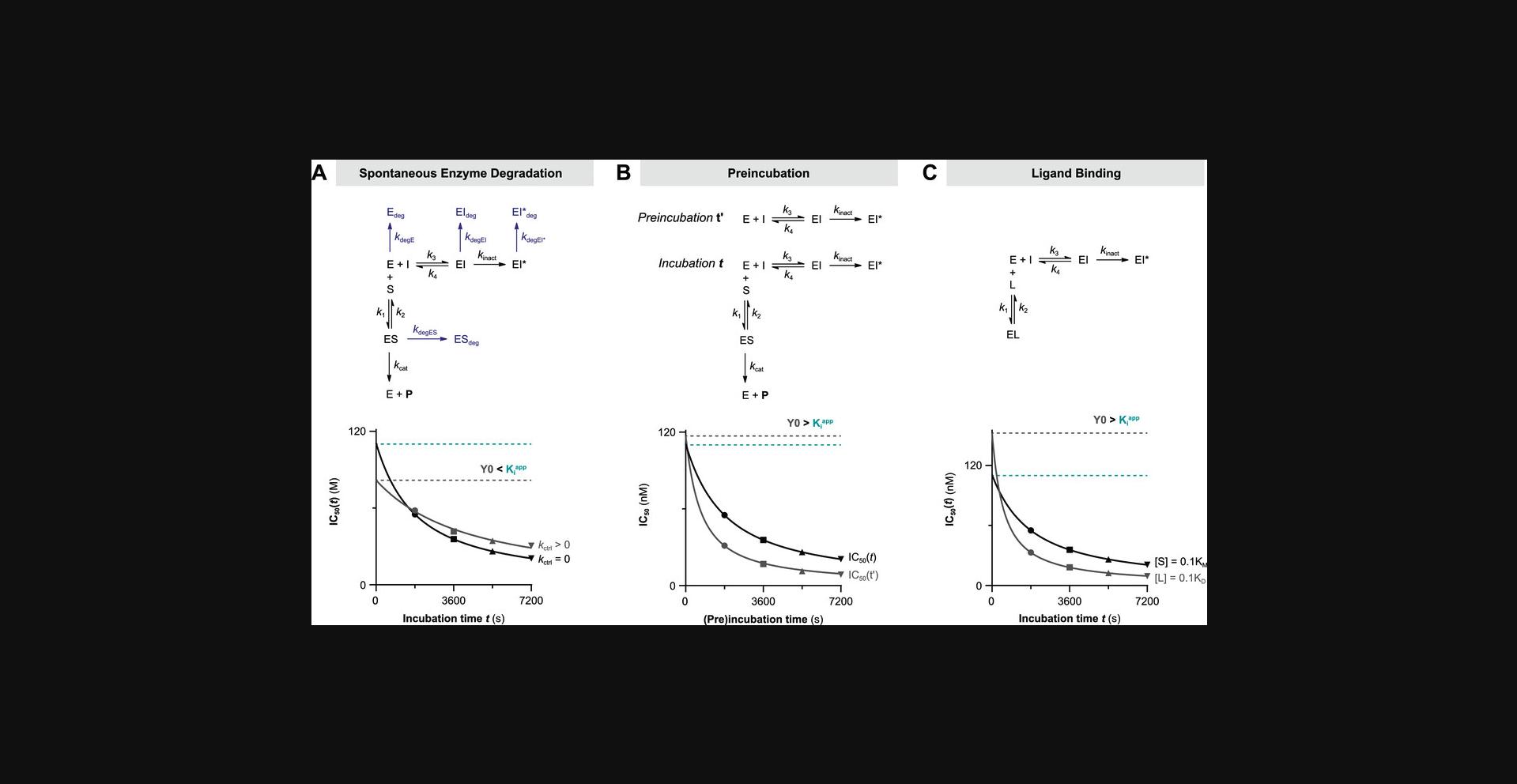

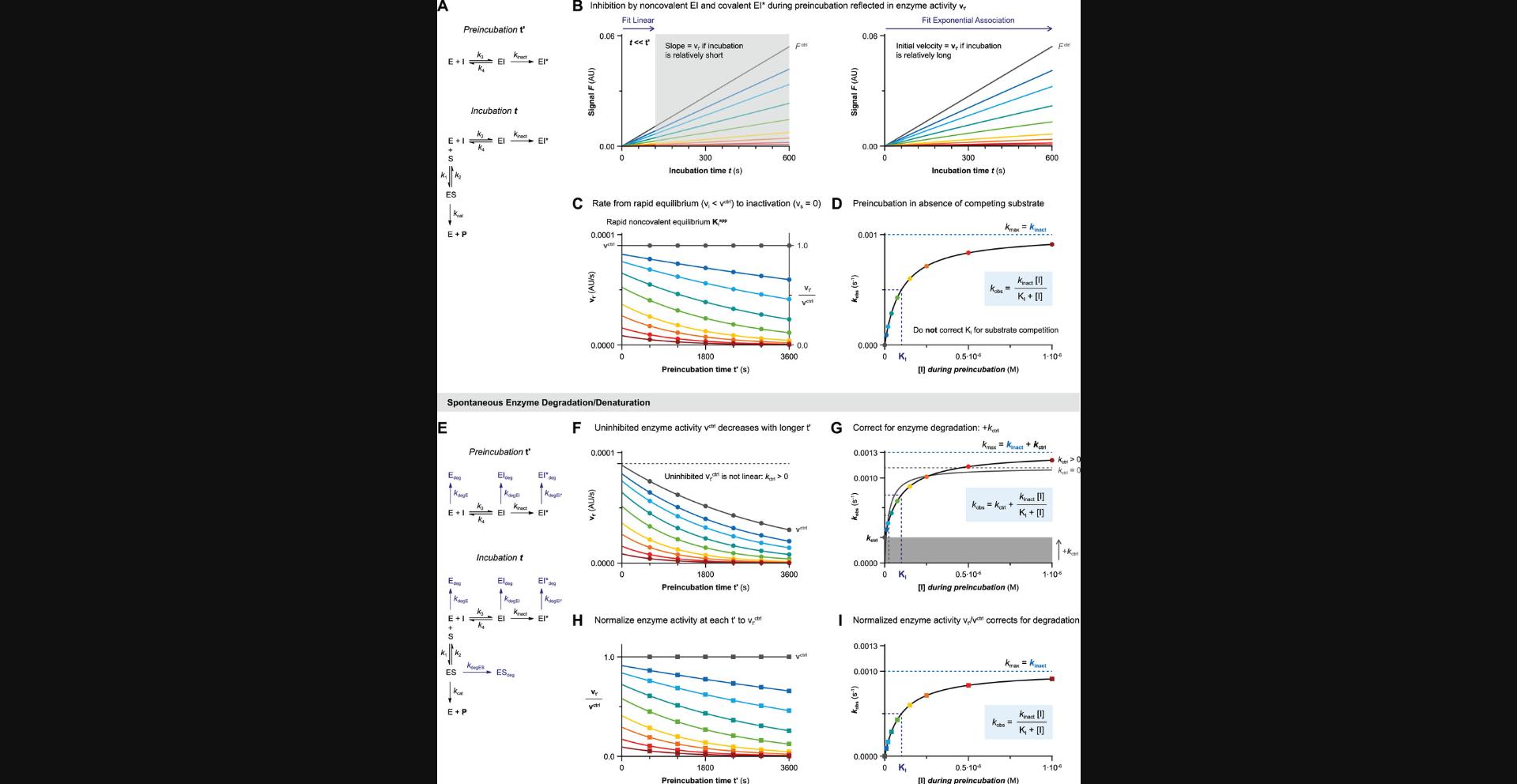

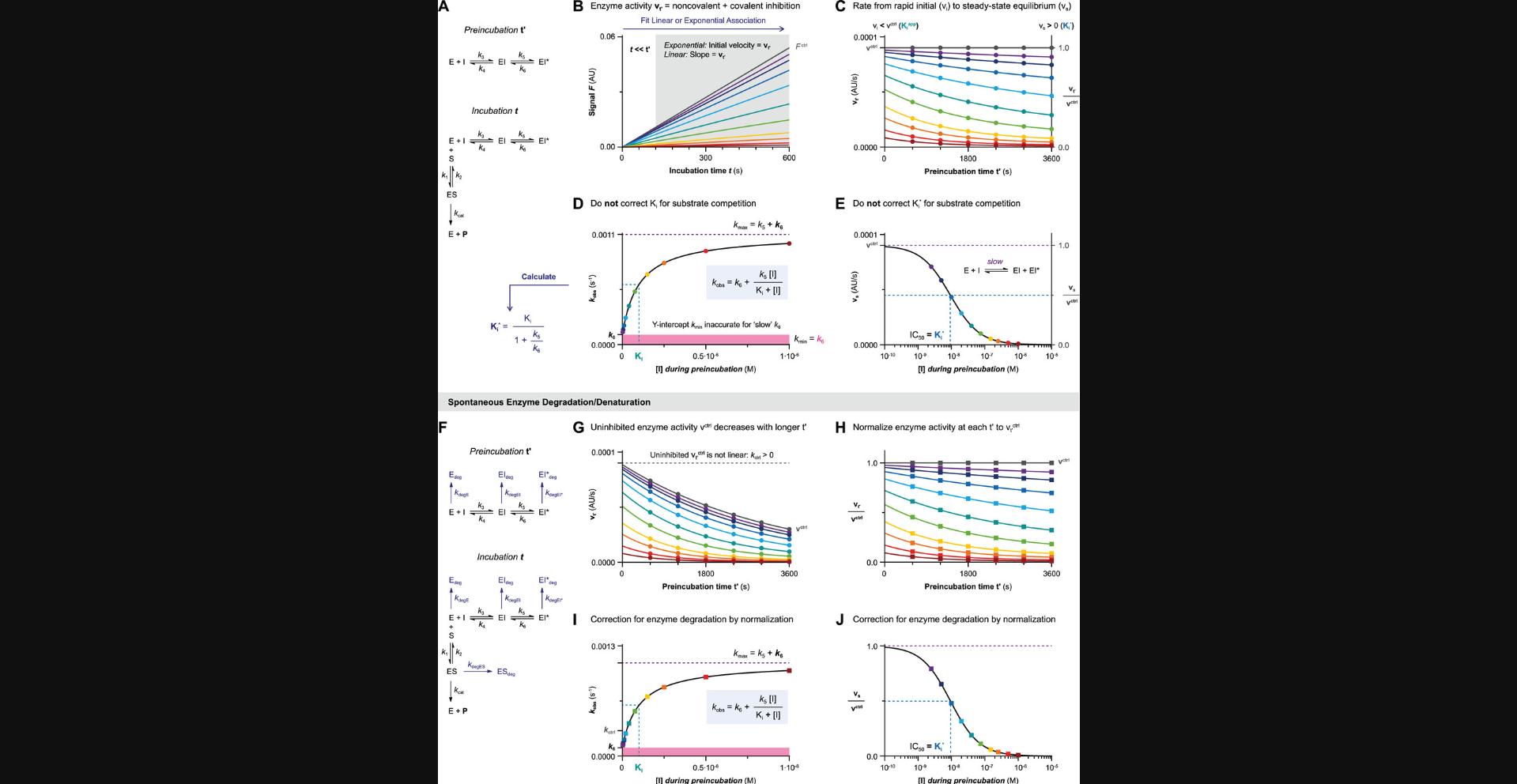

Basic Protocol III : Preincubation time–dependent inhibition without dilution

Basic Data Analysis Protocol 3 : Preincubation time–dependent inhibition without dilution

Basic Data Analysis Protocol 3Ai : Two-step irreversible covalent inhibition

Alternative Data Analysis Protocol 3Aii : Two-step irreversible covalent inhibition

Basic Data Analysis Protocol 3Bi : One-step irreversible covalent inhibition

Alternative Data Analysis Protocol 3Bii : One-step irreversible covalent inhibition

Basic Data Analysis Protocol 3C : Two-step reversible covalent inhibition

Basic Protocol IV : Preincubation time–dependent inhibition with dilution/competition

Basic Data Analysis Protocol 4 : Preincubation time–dependent inhibition with dilution

Basic Data Analysis Protocol 4Ai : Two-step irreversible covalent inhibition

Alternative Data Analysis Protocol 4Aii : Two-step irreversible covalent inhibition

Basic Data Analysis Protocol 4Bi : One-step irreversible covalent inhibition

Alternative Data Analysis Protocol 4Bii : One-step irreversible covalent inhibition

INTRODUCTION

Traditionally, drug design efforts were focused on small molecules that interact with their biological target through noncovalent interactions in a reversible manner. In contrast, covalent inhibitors have the ability to form a much stronger covalent bond with a nucleophilic amino acid residue at the target protein, which is positioned in close proximity to a reactive (electrophilic) moiety in the inhibitor (Ward & Grimster, 2021). Risks associated with covalent reactions that can take place not only with the desired target but also with off-target proteins, often undiscovered until late-stage clinical development, resulted in drug discovery programs moving away from candidates bearing intrinsically reactive electrophilic moieties (Bauer, 2015; Singh, Petter, Baillie, & Whitty, 2011). Nonetheless, the clinical success of covalent drugs that were being used in the clinic long before their mechanism of action was elucidated, which include aspirin and penicillin, along with the more recent clinical approval and success of targeted covalent inhibitors (TCIs) bearing moderately reactive electrophilic warheads, ultimately triggered the current resurgence of covalent drugs (Abdeldayem, Raouf, Constantinescu, Moriggl, & Gunning, 2020; De Cesco, Kurian, Dufresne, Mittermaier, & Moitessier, 2017; Singh et al., 2011).

The covalent inhibitor development process typically involves identification of noncovalent inhibitors by high-throughput screening (HTS), followed by modification with a moderately reactive electrophilic warhead to improve inhibition potency and selectivity (Engel et al., 2015; Zhang, Hatcher, Teng, Gray, & Kostic, 2019). Alternatively, an electrophilic fragment that forms a covalent bond with the desired enzyme target is first identified in covalent fragment–based drug discovery (Dalton & Campos, 2020; Kathman & Statsyuk, 2019; Resnick et al., 2019), followed by optimization of the noncovalent affinity and positioning of the electrophile. A prerequisite here is that the molecular target must contain a nucleophilic residue (e.g., cysteine, serine, lysine) to form a covalent bond with the electrophilic warhead of the inhibitor (Lagoutte, Patouret, & Winssinger, 2017; Ray & Murkin, 2019). Whether covalent adduct formation is reversible or irreversible depends on the selected electrophilic warhead (Bradshaw et al., 2015; Gehringer & Laufer, 2019; Lee & Grossmann, 2012; Shindo & Ojida, 2021). The PK-PD decoupling is one of the major advantages of irreversible inhibition: an infinite target residence time, resulting in a prolonged therapeutic effect after the inhibitor has been cleared from circulation (Abdeldayem et al., 2020; Barf & Kaptein, 2012; Gabizon & London, 2020; Kim, Hwang, Kim, & Park, 2021). Here, restoration of enzyme activity can only be achieved by de novo protein synthesis. At the same time, if the consequences of continued on-target inhibition are poorly understood, this same property can provide a safety concern. Consequently, inhibitors with a reversible covalent binding mode have become increasingly popular, with (tunable) target residence times ranging from several hours to multiple days (Bradshaw et al., 2015; Owen Dafydd et al., 2021; Serafimova et al., 2012).

Although traditional methods to evaluate inhibitor potency, such as determining half-maximal inhibitory concentration (IC50 values), are sufficient to identify hits in high-throughput screens, a more detailed kinetic evaluation is required to elucidate the structure-activity relationship (SAR) of irreversible covalent inhibitors (De Cesco et al., 2017; Harris et al., 2018; Holdgate, Meek, & Grimley, 2017). There are many extensive reviews on the history, development, and success of covalent inhibitors (Abdeldayem et al., 2020; De Cesco et al., 2017; Johnson, Weerapana, & Cravatt, 2010; Lagoutte et al., 2017), and experimental methods to assess undesired time-dependent inactivation (TDI) of CYP450 enzymes have been excellently reviewed (Stresser, Mao, Kenny, Jones, & Grime, 2014), but a comprehensive overview of experimental methods compatible with the desired covalent binding mode of TCIs targeting nucleophilic active-site residues has been missing. In the Strategic Planning section, we will introduce our customized set of interactive kinetic simulation scripts to study the kinetic concepts of different experimental methods, followed by a general background on (covalent) inhibitor binding modes, the assumptions on experimental enzyme activity assay conditions, and an introduction on time-dependent inhibitor kinetics. Our findings are discussed in detail in the section Experimental Methods and Data Analysis , where stepwise protocols are provided for four experimental methods with data analysis tailored to the different covalent binding modes. All are accompanied by an online available set of kinetic simulation scripts and troubleshooting guidelines, allowing readers to evaluate their covalent (ir)reversible inhibitor.

STRATEGIC PLANNING

This guide has been composed to aid readers that have identified an (ir)reversible covalent inhibitor and are contemplating which experimental method to select for the follow-up SAR analysis. Here, the performance of the enzymatic assay is not expected to be troublesome, but the challenge lies in the design of an assay method that complies with (often implied but not explicitly mentioned) assumptions on experimental conditions, and recognition of artifacts/errors in the interpretation of experimental outcome. As such, we assume that a functioning enzymatic assay with a robust read-out is already in place, and we will focus on the connection between (algebraic) data analysis methods and the respective assumptions on experimental conditions. It is important to note that this work is tailored to enzyme activity assays with a (fluorescence) read-out upon substrate processing to form a detectable product, and as such may not be compatible with other assay formats such as ligand binding competition assays or direct detection of the covalent enzyme-inhibitor adduct.

In the section ‘ Kinetic Simulations ’, we introduce the interactive kinetic simulation scripts used to illustrate the methods and kinetic concepts in this work. All figures are composed with in silico data generated in kinetic simulations, and can be recreated with the information in this section. The section ‘ Inhibitor Binding Modes ’ provides an overview of the (covalent) inhibition binding modes compatible with the methods in this work. It is paramount to select the appropriate algebraic model for data analysis, as the inhibitor binding mode changes the obtainable parameters as well as the compatibility with experimental methods. Covalent EI* adduct formation should be validated by direct detection with MS, X-ray crystallography or NMR (Harris et al., 2018; Liclican et al., 2020; Mons et al., 2019; Mons et al., 2021). Reversibility of covalent adduct formation is commonly assessed in rapid/jump dilution or washout assays with detection of regained enzymatic activity after dilution/washout (Copeland, Basavapathruni, Moyer, & Scott, 2011), MS detection of unbound inhibitor upon denaturation or digestion-mediated dissociation (Bradshaw et al., 2015), or competitive binding of a (selective) irreversible (activity-based) probe (Liclican et al., 2020; Smith et al., 2017). It is important to note that noncovalent binding can also irreversibly inhibit enzyme activity by aggregation or precipitation (Auld, Inglese, & Dahlin, 2017).

Next, we investigated which assumptions on experimental enzyme activity assay conditions are embedded in the algebraic models used for kinetic analysis. Our findings are outlined in the section ‘ Critical Parameters: Assumptions on Experimental Assay Conditions ’, highlighting which assumptions are crucial and what the consequences are when these assumptions are violated. Finally, we provide a kinetic background on time-dependent (covalent) inhibition in the section ‘ Time-dependent Inhibitor Potency ’. Readers new to the field of enzyme inhibition kinetics are strongly encouraged to familiarize themselves with the work of Copeland for a general introduction into enzyme kinetics (Copeland, 2000, 2013e) before studying advanced kinetic concepts associated with (ir)reversible covalent enzyme inhibition and their relation to experimental enzyme activity read-out.

Kinetic Simulations

Keeping assay requirements in mind, it may seem a daunting task to design, perform, and analyze proper inhibition experiments. In general, practice is the best teacher to get a feeling for these assays and the expected output. Kinetic simulations are essential to understand the importance of reaction conditions and support assay design optimization (Potratz, 2018). In such simulations, one can freely change the parameters to visualize the effect on the output and validate that kinetic parameters found after data analysis correlate with the input values. This design precludes assay artifacts and human error, and also outputs the underlying concentrations of the different reaction species (e.g., unbound enzyme, enzyme-substrate complex), illustrating the relevance of the experimental assay conditions. Finally, kinetic simulations can validate if fitted experimental parameters correlate with the experimental read-out (Pollard & De La Cruz, 2013) and aid the rational design of follow-up experiments by predicting the outcome.

Here, we use a set of customized kinetic simulation scripts based on numerical integration of the differential equations (Walkup et al., 2015) to simulate the time-dependent product concentration as well as the underlying concentrations of various enzyme species (e.g., unbound, bound to inhibitor or substrate). Some concentrations are essentially constant under specific assay conditions, and treating these parameters as constants rather than variables reduces the computing/simulation time. An overview of our kinetic scripts and the assumptions on experimental assay conditions can be found in Table 1. Since understanding kinetics can be greatly facilitated by the ability to adjust reaction conditions and changing parameters without using expensive reagents, we have made interactive versions of these simulation scripts available free of charge at https://tinyurl.com/kineticsimulations. We encourage our readers to perform simulations with their own kinetic parameters to visualize how the underlying concentrations of enzyme species affect the detected read-out, and to get a feeling for realistic values and assay conditions. We selected one model inhibitor for each binding mode to generate the figures that exemplify the methods described (the kinetic parameters of each model inhibitor can be found in Table S1 in Supporting Information). All figures in this work can be recreated with the information in Table 1 and Table S1.

- [I]0 = unbound inhibitor concentration at onset of inhibition, before (optional) enzyme binding. [I]t′ = unbound inhibitor concentration during preincubation, after (optional) enzyme binding. [I]t = unbound inhibitor concentration during incubation, after (optional) enzyme binding. [S]0 = unbound substrate concentration at onset of product formation, before enzyme binding. [S]t = unbound substrate concentration during incubation, after (optional) enzyme binding and product formation. Vt′ = reaction volume during preincubation. Vsub = volume containing substrate. Vt = reaction volume during incubation (Vt = Vsub + Vt′).

- a Available at https://tinyurl.com/kineticsimulations.

- b First-order spontaneous enzyme degradation/denaturation.

Our kinetic simulation scripts are tailored to competitive inhibition, where an intrinsically reactive inhibitor bearing an electrophilic warhead covalently targets a nucleophilic amino acid residue at the enzymatic substrate binding site, thus blocking substrate access (Copeland, 2013e; Holdgate et al., 2017). Other covalent binding modes [e.g., prodrugs (Strelow, 2017), covalent allosteric inhibitors (Lu & Zhang, 2017), and multi-step mechanism-based inhibitors (Tuley & Fast, 2018; Yang, Jamei, Yeo, Tucker, & Rostami-Hodjegan, 2005)] are outside the scope of this work, although the described experimental protocols can be useful in specific cases. For further instructions and detailed information on restrictions, we refer to the webpage itself.

At the start of the simulations, we define the (pre)incubation time. The preincubation time is the elapsed time since the onset of enzyme inhibition by mixing enzyme and inhibitor, but before the onset of product formation by adding substrate. The incubation time is the elapsed time since onset of product formation: after substrate addition. In this work, we will distinguish between incubation and preincubation by using different symbols for preincubation t′ (enzyme and inhibitor) and incubation t (enzyme, substrate and inhibitor) in all figures and equations to avoid confusion.

Inhibitor Binding Modes

Reversible noncovalent inhibitors inhibit enzymatic activity by formation of noncovalent EI complex in a single reaction step (Fig. 1A). When the initial unbound inhibitor concentration is equal to inhibition constant Ki, the concentration of unbound enzyme E will be equal to the concentration of inhibitor-bound enzyme complex EI after steady-state equilibrium has been reached. For traditional fast-binding reversible inhibitors this equilibrium will be reached almost instantly, as association rate constant k 3 and dissociation rate constant k 4 are fast. In this work, the term ‘reaction completion’ relates to the endpoint of enzyme-inhibitor binding, which refers to reaching an equilibrium for reversible inhibitors (Fig. 1A and 1B) or reaching full inactivation for irreversible inhibitors (Fig. 1C and 1D). Contrary to classic fast-binding inhibitors, time-dependent or slow-binding inhibition is observed when the steady-state equilibrium or irreversible inactivation is reached relatively slowly on the assay timescale (Copeland, 2013, 2013b, d). Typically, this is observed for inhibitors with a covalent binding mode (Fig. 1B-D), as formation of a covalent adduct is not an instantaneous process.

![Details are in the caption following the image Schematic overview of inhibitor binding modes (Tuley & Fast, 2018). E = unbound enzyme. I = unbound inhibitor. EI = noncovalent enzyme-inhibitor complex. EI* = covalent enzyme-inhibitor complex. An overview of kinetic constants can be found in Table S2 (see Supporting Information). Details on equilibrium constants are available in the Supporting Information. (A) Classic one-step reversible inhibition. Inhibitor potency ranking based on inhibition constant K<sub>i</sub> (M) or target residence time τ (s). (B) Two-step reversible covalent inhibition. Inhibitor potency ranking based on steady-state inhibition constant K<sub>i</sub>* (M) for total E + I <-> EI + EI* equilibrium or target residence time τ (s). (C) Two-step irreversible covalent inhibition (affinity label model). Inhibitor potency ranking based on inactivation efficiency: maximum rate of covalent adduct formation over inactivation constant k<sub>inact</sub>/K<sub>I</sub> (M<sup>−1</sup>s<sup>−1</sup>). (D) One-step irreversible covalent inhibition (residue-specific reagent model). Inhibitor potency ranking based on inactivation efficiency: k<sub>chem</sub> (M<sup>−1</sup>s<sup>−1</sup>) = k<sub>obs</sub>/[I] (M<sup>−1</sup>s<sup>−1</sup>).](https://static.yanyin.tech/literature_test/cpz1419-fig-0001-m.jpg)

Reversible covalent adduct formation (Fig. 1B) is a two-step process consisting of (rapid) initial association to form noncovalent EI complex (rapid equilibrium approximation , discussed in more detail in the section ‘ Critical Parameters: Assumptions on Experimental Assay Conditions ’) preceding covalent EI* adduct formation. Covalent EI* adduct is at equilibrium with the noncovalent EI complex, as covalent adduct formation is reversible (k 6 > 0), with inhibition constant Ki reflecting the initial noncovalent E + I <-> EI equilibrium and steady-state inhibition constant Ki* reflecting the steady-state (overall) E + I <-> EI + EI* equilibrium. Development of reversible covalent inhibitors typically involves optimization of overall affinity (reflected in low Ki* values), preferably by slowing dissociation rates (Fig. 1B). A slow off-rate (k off) is favorable, as this is reciprocal with the drug-target residence time τ (τ = 1/k off), and a longer residence time has been linked to superior therapeutic potency (Copeland, 2010; Copeland, Pompliano, & Meek, 2006). An overview of relevant kinetic parameters can be found in Table S2 (see Supporting Information).

Inhibition is considered irreversible when its residence time exceeds the normal lifespan of the target enzyme (Holdgate et al., 2017). Dissociation from covalent EI* adduct is negligible, resulting in full enzyme engagement when reaction completion is reached for irreversible covalent inhibitors (Fig. 1C and 1D). The irreversible binding mode changes the obtainable kinetic parameters to rank inhibitor potency, as the biochemical IC50 may vary depending on the (pre)incubation time (Holdgate et al., 2017; Singh et al., 2011). The potency of two-step irreversible inhibitors that engage in an initial noncovalent enzyme-inhibitor complex EI prior to formation of covalent adduct EI* is driven by noncovalent affinity reflected in inactivation constant KI along with the maximum rate of inactivation k inact (Fig. 1C). Rate constant k inact/KI is generally accepted as a more suitable measure of two-step irreversible inhibitor potency (Holdgate et al., 2017; Schwartz et al., 2014; Singh et al., 2011; Strelow, 2017), in an analogous fashion to k cat/KM reflecting the efficiency of enzymatic substrate conversion (detailed comparison can be found in Table S3 in Supporting Information). The binding mode becomes one-step when noncovalent equilibrium is non-existent, for example for highly reactive thiol-alkylating reagents (McWhirter, 2021; Strelow, 2017), with the parameter k chem or k obs/[I] reflecting potency/efficiency (Fig. 1D).

Drug development of irreversible covalent inhibitors is typically geared towards simultaneous improvement of the binding affinity (reflected in a lower KI value) and faster covalent bond formation (reflected in a higher k inact value) to generate irreversible covalent inhibitors with a high k inact/KI value for the desired enzyme target (Mah, Thomas, & Shafer, 2014; Schwartz et al., 2014), while minimizing the intrinsic reactivity with undesired enzymes such as GSH (Guan, Williams, Pan, & Liu, 2021; Lonsdale et al., 2017; Martin, MacKenzie, Fletcher, & Gilbert, 2019). Typical reported k inact/KI values of irreversible inhibitors range from 105-107 M−1s−1 for kinase inhibitors (Schwartz et al., 2014; Telliez et al., 2016; Zhai, Ward, Doig, & Argyrou, 2020), 101-105 M−1s−1 for protease inhibitors (Meara & Rich, 1995; Mons et al., 2019; Rocha-Pereira et al., 2014), 102-104 M−1s−1 for other target classes (Fell et al., 2020; Hansen et al., 2018; Lanman et al., 2020), to 10−2-102 M−1s−1 for covalent fragments (Johansson et al., 2019; Kathman, Xu, & Statsyuk, 2014). Ranges of clinically relevant k inact/KI values are highly dependent on the nucleophilicity of the targeted amino acid (cysteine typically being more reactive than serine) and concentration of naturally present competitors (e.g., ATP-competitive inhibitors need to overcome competition by ATP at physiological concentrations far exceeding the KM,ATP).

Critical Parameters: Assumptions on Experimental Assay Conditions

Experimental conditions should meet certain criteria in order to use algebraic fitting methods. In this paragraph, we focus on the assumptions (Michaelis – Menten Enzyme Kinetics , Enzyme Stability, Constant Uninhibited Product Formation Velocity , Rapid Equilibrium Approximation , Pseudo First-order Reaction Kinetics without Inhibitor Depletion) on the experimental conditions that are embedded in algebraic equations to analyze time-dependent (covalent) inhibition. Generally, these assumptions involve simplifying the enzyme-inhibitor binding reaction to a single rate-determining step along with fixing inhibitor/substrate concentrations to a constant value. There are two distinct types of algebraic analysis: linear regression (fitting straight curves, compatible with commonly available software such as Excel) and nonlinear regression (fitting exponential curves, requiring sophisticated data fitting software). Linear regression was the predominant method to analyze kinetic data, but has now been surpassed by the more accurate nonlinear regression (Perrin, 2017). For our analyses, we use least-squares nonlinear regression with GraphPad Prism (RRID:SCR_002798), but other software packages are available too (Rufer, 2021). Please consult the detailed (online) guide on how to implement user-defined equations for nonlinear regression in GraphPad Prism (Motulsky & Christopoulos, 2003; also see Internet Resources section at end of article).

To use algebraic fitting, the experiment should meet all the required conditions outlined below. More complex systems (such as bisubstrate assay or other binding modes like allostery) violate one or more of these and require a different method of fitting. For such systems, numerical integration with dedicated software packages [e.g., KinTek (Johnson, 2009), DynaFit (Kuzmič, 2009)] is recommended. These packages are very powerful, and can fit anything with good error even when the model does not reflect the biological situation (Mayer, Khairy, & Howard, 2010). For these complex systems, it is crucial to ensure that the initial values are reasonable and the amount of (orthogonal) data is sufficient for the amount of parameters that are fitted. The first step, however, whether working with complex systems or reactions with a single rate-determining step, should always be optimization of the experimental conditions.

Michaelis–Menten enzyme kinetics

All experimental methods in this manuscript are based on enzyme activity assays with multiple turnovers per enzyme, with enzyme release after product formation. We assume that the uninhibited enzymatic substrate processing reaction (E + S <-> ES → E + P) complies with Michaelis–Menten enzyme kinetics (Pollard & De La Cruz, 2013; Rufer, 2021). The concentration of unbound substrate has to be constant ([S]t = [S]0) and not depleted by engagement in a (non)covalent complex ES ([ES]t < 0.1[S]0) or conversion into product. Therefore, substrate is added in a large excess over the enzyme ([S]0 > 10[E]0), and the uninhibited velocity of product formation (vctrl) is calculated over the linear part corresponding to less than 10% substrate conversion ([P]t < 0.1[S]0) (Wu, Yuan, & Hodge, 2003). The signal corresponding to 10% substrate conversion can be estimated from a product calibration/titration curve (Dharadhar et al., 2019; Janssen et al., 2019) to avoid substrate depletion. The effect of substrate depletion can be investigated with the kinetic simulation script KinSubDpl. More complex enzymatic (bisubstrate) assays (Copeland, 2000) are outside of the scope of this work. However, the methods described herein could still be applicable under pseudo-single substrate (Hit-and-Run) conditions.

Enzyme stability

Unless otherwise noted, time-dependent decrease of enzyme activity is attributed solely to the presence of a (slow-binding) inhibitor. It is thus assumed that the enzyme activity is constant throughout the whole experiment, although this does not necessarily reflect the actual experimental situation. Recombinant enzymes do not have an eternal life; thus, time-dependent loss of enzyme activity will inevitably occur due to spontaneous protein denaturation, degradation, or unfolding (Miyawaki, Kanazawa, Maruyama, & Dozen, 2017). The Selwyn test is a relatively simple test to see if time-dependence of uninhibited enzyme activity is due to (spontaneous) enzyme inactivation (Selwyn, 1965). Spontaneous enzyme degradation/denaturation is similar to radioactive decay in a sense that inactivation is a first-order reaction (degradation rate = k degE×[E]). Enzyme stability might be promoted by optimization of the assay buffer, and is less significant at shorter (pre)incubation times, but degradation cannot completely be avoided. Therefore, we included data analysis methods to account for spontaneous first-order enzyme degradation/denaturation. Cannibalistic proteases (Ferrall-Fairbanks, Kieslich, & Platt, 2020) follow a second-order (auto)proteolysis rate (degradation rate = k degE×[E]2) and are as such outside of the scope of these methods. In simulations to illustrate the methods described herein (with kinetic simulation scripts KinDeg and KinVolDeg), we assumed that first-order decay is uniform for all enzyme species (k degE = k degES = k degEI = k degEI*) and combined the individual degradation rates into the enzyme degradation rate constant k deg.

Constant uninhibited product formation velocity

The uninhibited controls should be linear for the whole measurement when analyzing time-dependent inhibition. There are various factors contributing to a slight time-dependent decrease of product formation velocity in the absence of inhibitor (Copeland, 2000), thus violating this assumption. An overview of common troubleshooting options is listed in Table 3 (located in the troubleshooting section at the end of this document). As discussed above, substrate depletion ([P] > 0.1[S]0) negatively influences the linearity over time, as does product inhibition ([P] > 0.1KD,P). Fortunately, this can be avoided by decreasing the enzyme concentration and/or shortening the incubation time to reduce substrate turnover, thereby lowering the absolute and relative product concentration. Other factors, such as quenching of the fluorescent product signal by photobleaching (Johnson, 2010), can make the results look nonlinear. This effect can be reduced by increasing the measurement interval and/or reducing the number of excitation cycles. Finally, optimization of assay conditions can minimize the effect of spontaneous loss of enzyme activity (k deg > 0), but cannot be resolved completely. In this work, we will refer to the overall rate of nonlinearity in the uninhibited control (k obs of [I] = 0) with the symbol k ctrl, regardless of the underlying mechanism that causes the time-dependent decrease of product formation velocity.

Rapid equilibrium approximation

Algebraic analysis of (covalent) inhibition is based on the assumption that time-dependent inhibition is driven by a single rate-determining step. For two-step covalent inhibitors (Fig. 1B and 1C), this means that the noncovalent E + I <-> EI equilibrium that precedes covalent EI* adduct formation should be reached almost instantly after the onset of inhibition. After this rapid equilibrium, a much slower step of covalent adduct formation follows (k inact << k 4). Whether the noncovalent equilibrium indeed is reached rapidly is an intrinsic inhibitor property, and (kinase) inhibitors with a low-nM noncovalent potency are likely to violate this assumption: the association rate constant is diffusion-limited (k 3 ≤ 109 M−1s−1), and thus k 4 must be relatively slow if Ki ≤ 10-8 M (Kuzmič, 2020a). Unfortunately, a slow initial, noncovalent step is not easily recognized from raw kinetic data, resulting in overestimation of the rate of inactivation k inact and underestimation of the inactivation constant KI with algebraic rather than numerical data analysis.

The inactivation constant KI approximates inhibition constant Ki (KI ≈ Ki) when covalent bond formation is driven by the rate-determining conversion of noncovalent complex EI into covalent adduct EI* (k inact << k 4) (Fig. 1C), analogous to the Briggs–Haldane treatment of enzyme-substrate kinetics where KM ≈ KS if k cat is rate-limiting (McWhirter, 2021). Consequently, Ki and KI may have the same value, but they are not interchangeable, and it is as such recommended to report k inact/KI rather than k inact/Ki.

Pseudo first-order reaction kinetics without inhibitor depletion

Algebraic analysis of (covalent) inhibition is typically based on the assumption that the unbound inhibitor concentration is a constant value ([I]t = [I]0) unaffected by enzyme binding (Pollard & De La Cruz, 2013). This assumption is only valid when the inhibitor is present in large excess with respect to the enzyme ([I]0 > 10[E]0) at reaction initiation. The enzyme occupancy after reaching the noncovalent equilibrium is driven solely by the excess inhibitor concentration relative to the (apparent) inhibition constant Kiapp: [EI]eq/[E]0 = 1/(1 + (Kiapp/[I])). The effect of inhibitor depletion can be investigated with the kinetic simulation script KinInhDpl. Violation of this assumption results in an appreciable reduction of the remaining population of unbound inhibitor upon complexation with enzyme. Consequently, the inhibitor occupancy at equilibrium no longer reflects the apparent inhibition constant Kiapp because the equilibrium is now driven by both enzyme and inhibitor concentration (Fig. 2A). Algebraic correction for inhibitor depletion ([I]t < [I]0) to find the equilibrium constant Ki is often performed for one-step reversible inhibitors displaying tight-binding behavior (with low inhibitor concentrations because Kiapp approaches [Etotal]), by fitting the (steady-state) equilibrium product formation velocity to (variants of) Morrison's quadratic equation (Copeland, 2013c; Murphy, 2004) that treat the inhibitor concentration as a variable rather than a constant value (more details in Supporting Information). However, these equations are only compatible with inhibitors with a reversible binding mode after equilibrium has been reached, and are thus not suitable for irreversible inhibition.

![Details are in the caption following the image Consequences of inhibitor depletion. Simulated with KinInhDpl for 50 nM inhibitor C with 5 nM enzyme ([I]<sub>0</sub> = 10[E]<sub>0</sub>) or 50 nM enzyme ([I]<sub>0</sub> = [E]<sub>0</sub>). (A) Inhibitor depletion (blue line) results in lower noncovalent equilibrium occupancy [EI]<sub>eq</sub> calculated with Morrison's quadratic equation (available in Supporting Information) and slower reaction rates resulting in longer incubation time to reach full inactivation than for excess inhibitor (black line). (B) First-order reaction conditions with constant half-life t½ when inhibitor is present in excess (left). Second order reaction conditions with variable half-life t½ and longer overall reaction time when inhibitor is depleted (right).](https://static.yanyin.tech/literature_test/cpz1419-fig-0002-m.jpg)

Binding of inhibitor to enzyme is, in principle, a second-order reaction: the association rate depends on the concentration of unbound enzyme as well as unbound inhibitor, which both decrease upon formation of association product EI. Towards the end of the reaction, the reaction rate is significantly slower when less of the unbound components are left. Algebraic analysis of second-order (ir)reversible association curves is complicated (data not included, simulated with simulation script KinInhDpl), even for inhibitors with a one-step binding (Fig. 1); thus, it is strongly advised to analyze second-order reactions of two-step (ir)reversible inhibitors by numeric integration (Copeland, 2013a). However, as mentioned above, unbound inhibitor concentrations remain more or less constant during the reaction if the inhibitor is present in excess at reaction initiation ([I]0 > 10[E]0). Consequently, the second-order binding reaction of enzyme and inhibitor behaves like a first-order reaction when the inhibitor is present in excess: pseudo-first order reaction kinetics (Copeland, 2013a). The time-dependent association reaction for a (pseudo-)first order reaction has a constant half-life t½, and the progress curves can be fitted to standard one-phase exponential association equations (Fig. 2B, left), as will be discussed in more detail in the next section.

Second-order kinetic association reactions require a longer overall time to reach reaction completion of the enzyme-inhibitor binding reaction (inactivation or equilibrium) with a variable half-life t½ (Fig. 2B, right), because the association reaction rate slows down when the remaining unbound inhibitor concentration decreases. For two-step (ir)reversible inhibitors, the time-dependent reduction in covalent reaction rate is a direct consequence of the decreasing noncovalent occupancy upon inhibitor depletion. The rate-determining step of covalent adduct formation is preceded by noncovalent complex EI formation, and is thus limited by noncovalent occupancy, which decreased over time.

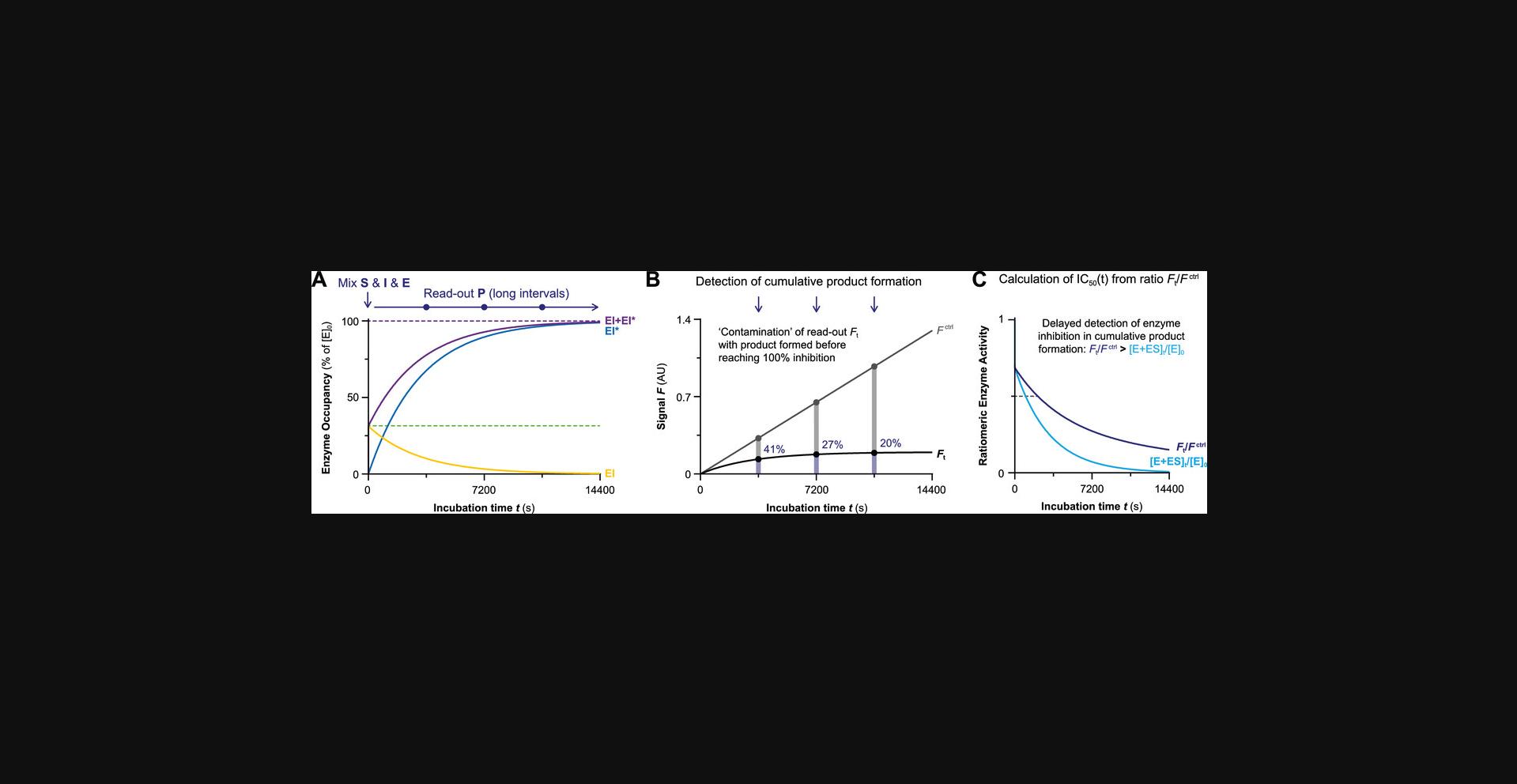

Time-Dependent Inhibitor Potency

Methods to analyze time-dependent inhibitors are based on the fact that it takes time to reach completion, and we use this information to obtain kinetic parameters. Under pseudo-first-order conditions (Copeland, 2013a) based on a single rate-determining step, inhibitor binding follows an exponential one-phase association reaction (Pollard & De La Cruz, 2013) from the rapid initial binding (rapid equilibrium approximation) to (slowly) reaching a plateau at reaction completion : equilibrium for reversible inhibitors (Fig. 3A, right) or inactivation for irreversible inhibitors (Fig. 3A, right). The incubation time to reaction completion is infinite, but after five half-lives (t = 5t½) reaction progress is at 97%, which is generally sufficient to be considered reaction completion (Fig. 3A). Reaction half-life t½ is inversely related to observed reaction rate k obs (Copeland, 2013a): t½ = LN(2)/k obs. k obs is the experimental reaction rate for reaction progress from initial binding to reaction completion under the specific assay conditions. Inhibitor concentration as well as competing substrate concentration are major contributors to the observed reaction rate k obs. The experimental k obs value can be obtained by fitting the time-dependent binding/occupancy curve to exponential one-phase association Equation I (Fig. 3B) from initial to final enzyme occupancy.

![Details are in the caption following the image Time-dependent Inhibition and Reaction Completion. Simulated with KinGen for 1 pM enzyme with substrate S1. (A) Time-dependent enzyme occupancy simulated for 50 nM one-step reversible inhibitor A (left) or two-step irreversible inhibitor C (right) in presence of 100 nM substrate S1. Each half-life t½, the occupancy increases by 50% (of the remaining span). After 5t½, occupancy is at 97% of its maximum (equilibrium concentration [EI]<sub>eq</sub> or total enzyme concentration [E]<sub>0</sub>) and generally considered as reaction completion. Half-life t½ is inversely related with observed reaction rate k<sub>obs</sub> (under pseudo-first order conditions). (B) Bounded exponential association Equation I from initial occupancy (rapid equilibrium) to final occupancy (reaction completion). (C) Progress curve of time-dependent product formation for enzyme inhibition in Figure 3A. Product formation velocity (slope, in AU/s), reflecting the (remaining) enzyme activity decreases until reaction completion is reached (steady-state equilibrium or inactivation). (D) Exponential association Equation II from initial velocity v<sub>i</sub> (rapid equilibrium) to final velocity v<sub>s</sub> (reaction completion). (E) k<sub>obs</sub> curves in absence (black, [S] = 0) or presence (gray, [S] = 2K<sub>M</sub>) of competing substrate. Apparent values are not yet corrected for substrate competition. (F) Two-step irreversible covalent inhibitors display one-step behavior at non-saturating inhibitor concentrations ([I] ≤ 0.1K<sub>I</sub>). Fit straight line with Y-intercept = k<sub>ctrl</sub> to obtain k<sub>chem</sub> = (k<sub>inact</sub>/K<sub>I</sub>) from the linear slope. (G) Two-step irreversible covalent inhibitors display one-step behavior at saturating inhibitor concentrations ([I] > 10K<sub>I</sub>). Distinguish from non-saturating inhibitor concentrations in Figure 3F: Y-intercept > k<sub>ctrl</sub> when fitting a straight line to the k<sub>obs</sub> curve.](https://static.yanyin.tech/literature_test/cpz1419-fig-0003-m.jpg)

Biochemical inhibitor potency is seldom assessed by direct observation of enzyme complex/adduct. Typically, enzyme inhibition is indirectly assessed in in vitro assays with a detectable read-out for product formation as a measure of (remaining) enzyme activity. Consequently, reversible enzyme inhibition may have reached the enzyme-inhibitor binding equilibrium (reaction completion), but not all enzyme is occupied (unless [I] >> Kiapp) so the remaining fraction of unbound enzyme continues to convert substrate into product (Fig. 3C, left). The reaction is no longer accurately reflected by Equation I (Fig. 3B), as product concentration at reaction initiation does not reflect the initial binding equilibrium, and product concentration does not reach a plateau after reaching the noncovalent equilibrium (reaction completion) for reversible inhibitors. Therefore, time-dependent product formation is fitted to exponential one-phase association Equation II (Fig. 3D) to obtain observed reaction rate k obs from initial to final product formation velocity. For irreversible inhibitors, the initial velocity vi reflects the (remaining) enzyme activity after rapid noncovalent association, and final velocity vs = 0 as this reflects full enzyme inactivation.

Typically, substrate competition assays are run at various inhibitor concentrations, and the concentration-dependent k obs is fitted to obtain kinetic parameters (Fig. 3E). In this work, equations and simulations are tailored to competitive binding of inhibitor and substrate (Holdgate et al., 2017; Rufer, 2021). Consequently, the observed reaction rate k obs (Fig. 3E) in the presence of competing substrate is slower, and apparent kinetic constants (marked with app) need to be corrected for substrate competition to reflect the kinetic inhibitor potency. Unless otherwise noted, nonlinearity in the uninhibited control k ctrl (k obs of [I] = 0) is assumed to be 0. The relation between k obs and inhibitor concentration holds important information on the inhibitor binding mechanism. A linear k obs increase with inhibitor concentration is a hallmark of a one-step binding mode, as reaction rates are only limited by experimental factors such as solubility. Plots of k obs against two-step inhibitor concentrations are hyperbolic, as the experimental covalent EI* association rate is limited by EI occupancy, which reaches its maximum (k inact or k 5) at saturating inhibitor concentration, as shown in Figure 3E: [I] > 10KI for 2-step IRREV or [I] > 10Ki for 2-step REV. An exception to this general observation is inhibitors with a two-step binding mode that will display a linear relationship (Strelow, 2017) when assessed at all non-saturating inhibitor concentrations (Fig. 3F) or all saturating inhibitor concentrations (Fig. 3G). These one-step binding behaviors can be distinguished from the Y-intercept (Y0 = k ctrl for [I] << Kiapp and Y0 > k ctrl for [I] >> Kiapp) along with the noncovalent inhibition of enzyme activity (vi = vctrl for [I] << Kiapp) and vi < vctrl for [I] >> Kiapp).

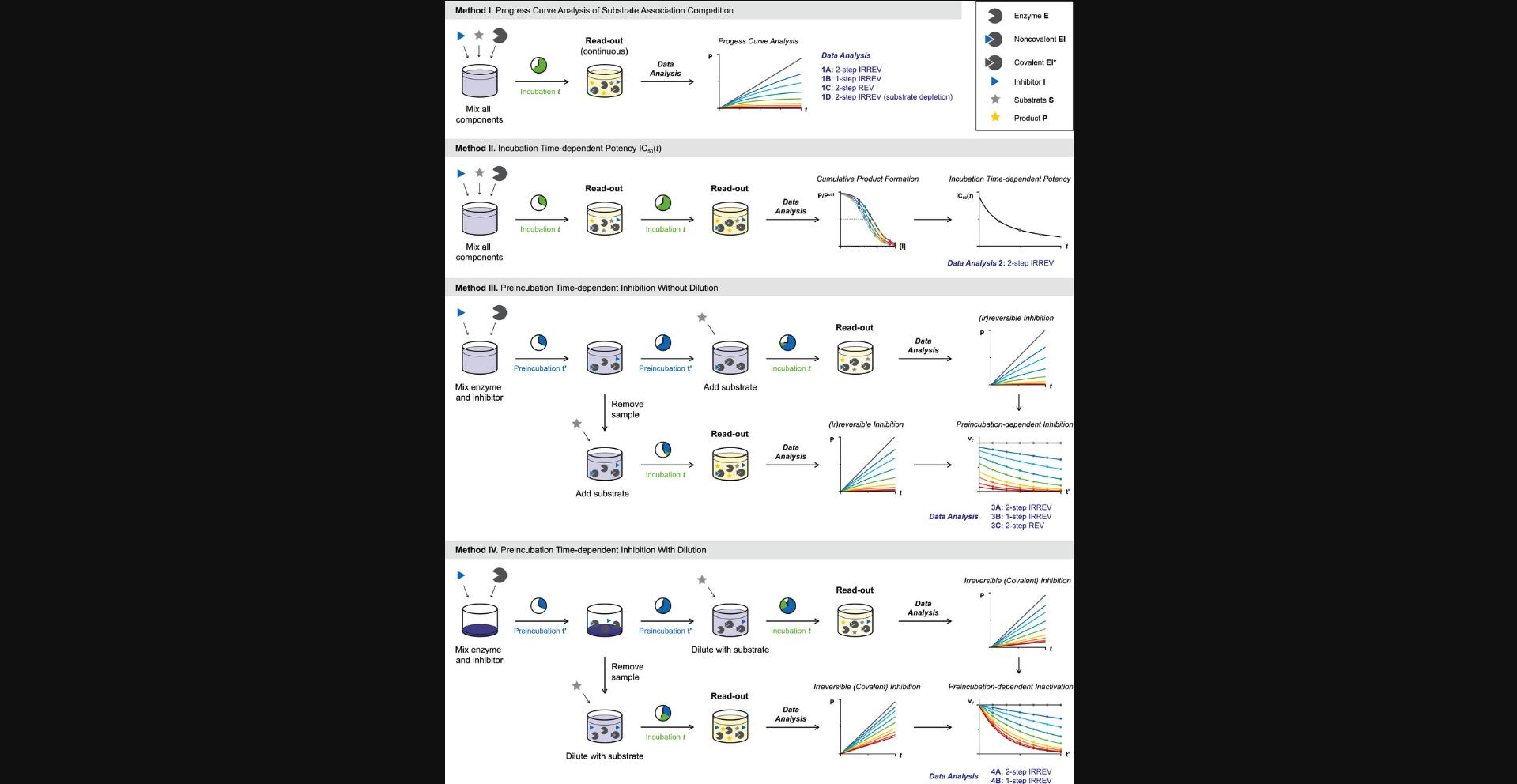

EXPERIMENTAL METHODS AND DATA ANALYSIS

We will discuss four methods in this work (Progress Curve Analysis of Substrate Association Competition, Incubation Time–Dependent Potency IC50(t), Preincubation Time-Dependent Inhibition without Dilution, and Preincubation Time–Dependent Inhibition with Dilution/Competition) with accompanying data analysis protocols depending on the inhibitor binding mode (Fig. 4; also see Table 2). For each method, we will start with an overview of the general conceptual background and assay design considerations. Subsequent data analysis is subdivided into protocols tailored to a specific inhibitor binding mode, and for each data analysis protocol we will illustrate the ‘ideal’ situation with kinetic simulations to guide interpretation of results. A practical comment on the nomenclature used: we use the word ‘fit’ for nonlinear fits of raw data (in e.g., GraphPad as part of data analysis protocols) and ‘calculate’ to denote that we calculate parameters from experimental values (in e.g., EXCEL as part of sample calculations). Furthermore, pointers on identification of deviations such as nonlinearity in the uninhibited control (k ctrl > 0) will be given along with algebraic corrections or troubleshooting options to resolve issues.

| Method | Data analysis Protocol | Binding mode | Readout and experimental conditionsa | Obtainable kinetic parameters | Comments/remarks | Literature reference |

|---|---|---|---|---|---|---|

| I | 1A | 2-step IRREV | Continuous | kinact, KI & kinact/KI | Progress curve analysis is favored for very potent inhibitors as competing substrate is present during incubation. Optimization of reaction conditions to minimize assay artefacts can be challenging but rewards with the most simple experimental procedure. | Copeland, 2013b |

| 1B | 1-step IRREV | Continuous | kchem | |||

| 2-step IRREV | Continuous [I] << Kiapp | kinact/KI | ||||

| 1C | 2-step REV | Continuous kctrl << k6 | Ki* | Progress curve analysis is disfavored for 2-step reversible inhibitors as algebraic correction for spontaneous loss of enzyme activity is NOT possible. | ||

| 1D | 2-step IRREV | Continuous [P]t > 0.1[S]0 [S] << 0.1KM | kinact, KI & kinact/KI | Algebraic correction for substrate depletion. | Kuzmič et al., 2015 | |

| II | 2 | 2-step IRREV | Continuous/Quenched kctrl = 0 | kinact, KI & kinact/KI | Incubation time-dependent potency enables use of quenched assays but is sensitive to spontaneous loss of enzyme activity. | Krippendorff et al., 2009 |

| III | 3Ai | 2-step IRREV | Continuous/Quenched [S] << KM Vsub << Vt′ | kinact, KI & kinact/KI | Preincubation without dilution is favored for inhibitors with low potency as preincubation is performed in absence of competing substrate. Experimentally, assays are more time-consuming than Methods I & II. Data Analysis Protocols 3Ai and 3Bi are favored for comparison of multiple inhibitors on a single target. Data Analysis Protocols 3Aii and 3Bii are favored for selectivity evaluation of a single inhibitor on multiple targets. | Ito et al., 1998 |

| 3Aii | 2-step IRREV | Continuous/Quenched [S] << KM Vsub << Vt′ | kinact, KI & kinact/KI | |||

| 3Bi | 1-step IRREV | Continuous/Quenched [S] << KM Vsub << Vt′ | kchem | |||

| 2-step IRREV | Continuous/Quenched [S] << KM Vsub << Vt′ [I] << KI | kinact/KI | ||||

| 3Bii | 1-step IRREV | Continuous/Quenched [S] << KM Vsub << Vt′ | kchem or kobs/I | |||

| 2-step IRREV | Continuous/Quenched [S] << KM Vsub << Vt′ [I] << KI | kinact/KI | ||||

| 3C | 2-step REV | Continuous/Quenched [S] << KM Vsub << Vt′ | Ki* | Favored for 2-step REV inhibitors, with algebraic correction for spontaneous loss of enzyme activity by normalization. | ||

| IV | 4Ai | 2-step IRREV | Continuous/Quenched [S] >> KM Vsub >> Vt′ | kinact, KI & kinact/KI | Preincubation without dilution is favored for inhibitors with low (noncovalent) affinity, or to study the contribution of covalent bond formation. Data Analysis Protocols 4Ai and 4Bi are favored for comparison of multiple inhibitors on a single target. Data Analysis Protocols 4Aii and 4Bii are favored for selectivity evaluation of a single inhibitor on multiple targets. | Kitz & Wilson, 1962 |

| 4Aii | 2-step IRREV | Continuous/Quenched [S] >> KM Vsub >> Vt′ | kinact, KI & kinact/KI | |||

| 4Bi | 1-step IRREV | Continuous/Quenched [S] >> KM Vsub >> Vt′ | kchem | |||

| 2-step IRREV | Continuous/Quenched [S] >> KM Vsub >> Vt′ [I] << KI | kinact/KI | ||||

| 4Bii | 1-step IRREV | Continuous/Quenched [S] >> KM Vsub >> Vt′ | kchem or kobs/I | |||

| 2-step IRREV | Continuous/Quenched [S] >> KM Vsub >> Vt′ [I] << KI | kinact/KI or kobs/I | ||||

- a General assay conditions for all methods (unless otherwise noted/specified): [I] > 10[E]. [S] > 10[E]. [P]t < 0.1[S]0.

Methods I and II are based on incubation time–dependent enzyme inhibition (Fig. 4). Here, substrate and inhibitor are mixed, and the reaction is initiated by addition of enzyme: i.e., simultaneous onset of product formation and enzyme inhibitor. Methods III and IV are based on enzyme inhibition after preincubation. Here, enzyme is preincubated with inhibitor before substrate addition. Two major factors contribute to selection of the appropriate experimental method for your enzymatic inhibition assay: the available enzyme activity assay and the inhibitor binding mode. Recombinant enzyme inhibition is assessed in an in vitro enzyme activity assay with detectable product formation (Acker & Auld, 2014; Bisswanger, 2014). This can be a continuous read-out for enzymatic processing of fluorogenic substrates (e.g., fluorescence intensity, FRET) or be a stopped/quenched assay that may require a secondary development/quenching or separation step to detect the formed product (or remaining substrate) such as LC/MS-based assays, conversion of radiolabeled substrate, and commercial assay technologies including ADP-GloTM (Promega) ATP consumption/ADP production assays, HTRF® KinEASETM (Cisbio) and Z′-LYTE (Invitrogen) phosphorylation assays, and Amplex® Red (Invitrogen) hydrogen peroxide/peroxidase assays (Acker & Auld, 2014; Bisswanger, 2014). Method I is only compatible with homogeneous enzymatic assays that allow continuous read-out, such as cleavage of fluorogenic reporter peptides by proteases. Methods II-IV are also compatible with quenched/stopped assays with development step prior to read-out.

METHOD I: PROGRESS CURVE ANALYSIS OF SUBSTRATE ASSOCIATION COMPETITION

Progress curve analysis is an established method for kinetic analysis of slow-binding inhibitors based on continuous detection of product formation after the substrate processing/product formation reaction has been initiated by addition of enzyme to a mixture of inhibitor and substrate (Fig. 5A). A single measurement at each inhibitor concentration is sufficient, which is convenient when comparing the potency of multiple inhibitors on the same target. However, this method requires the availability of an activity assay format with a continuous read-out, thereby limiting the substrates that can be used. Additionally, assay optimization for progress curve analysis is labor intensive: it is not uncommon to perform multiple pilot experiments to find suitable concentrations of substrate, enzyme, and inhibitor that ensure linear product formation in the uninhibited control (consult Table 3 in the troubleshooting section near the end of the article for troubleshooting).

![Details are in the caption following the image Method I: Progress curve analysis of substrate association competition. Simulated with KinGen for 1 pM enzyme and 100 nM substrate S1. (A) The reaction between enzyme, inhibitor, and substrate is initiated by addition of enzyme. Product formation is monitored continuously to detect the time-dependent enzyme activity. Top: simulated for 50 nM reversible two-step inhibitor B. Bottom: simulated for 50 nM irreversible two-step inhibitor C. Enzyme inhibition increases with time-dependent formation of covalent EI* until reaching reaction completion. Initially, total enzyme occupancy [EI + EI*] reflects the rapid noncovalent equilibrium [EI]<sub>eq</sub>. At reaction completion (t > 5t½), total enzyme occupancy EI + EI* reflects the steady-state equilibrium (reversible) or inactivation (irreversible). (B) Typical progress curves for enzyme activity in presence of time-dependent inhibitors. Time-dependent product formation decreases exponentially from initial velocity v<sub>i</sub> (dashed green line) to the steady-state velocity v<sub>s</sub> (dashed purple line) at reaction completion (t > 5t½). v<sub>i</sub> = v<sup>ctrl</sup> when [I] << K<sub>i</sub><sup>app</sup> (and for one-step inhibitors) with v<sup>ctrl</sup> = linear product formation in uninhibited control (gray line). Simulated for 50 nM one-step reversible inhibitor A, two-step reversible inhibitor B, one-step irreversible inhibitor D, or two-step irreversible inhibitor C. (C) General exponential association Equation II to fit progress curves of time-dependent inhibition. Parameters are constrained depending on the inhibitor binding mode. Irreversible inhibition: v<sub>s</sub> = 0 (inactivation at reaction completion). One-step inhibition: v<sub>i</sub> = v<sup>ctrl</sup> (noncovalent complex is not significant at non-saturating inhibitor concentrations). F<sub>t</sub> = time-dependent signal resulting from product formation (in AU). F<sub>0</sub> = Y-intercept = background signal at reaction initiation (in AU). v<sub>i</sub> = initial product formation velocity (in AU/s). v<sub>s</sub> = final/steady-state product formation velocity (in AU/s). t = incubation time after enzyme addition (in s). k<sub>obs</sub> = observed rate of time-dependent inhibition from initial v<sub>i</sub> to final v<sub>s</sub> (in s<sup>−1</sup>). Also fit the uninhibited/fully inhibited controls to obtain reference values for uninhibited velocity v<sup>ctrl</sup> and the rate of nonlinearity in the uninhibited control k<sub>ctrl</sub>.](https://static.yanyin.tech/literature_test/cpz1419-fig-0005-m.jpg)

For ‘slow-binding’ inhibitors, the slope of time-dependent product formation exponentially decreases from initial product formation velocity vi (rapid noncovalent inhibition) to the final product formation velocity vs (reaction completion) (Fig. 5B) (Copeland, 2013b). The progress curve of time-dependent product formation (as detected signal F t in AU) is fitted to a general exponential inhibitor association Equation II (Fig. 5C) to obtain the observed rate of reaction completion k obs (in s−1) from initial velocity vi (in AU/s) to final velocity vs (in AU/s). One-step or two-step binding modes can be identified by (visual) inspection of the initial velocity (Fig. 5B). The value of initial velocity vi is inhibitor concentration–dependent for two-step (ir)reversible inhibitors that form a rapid (noncovalent) equilibrium (vi < vctrl) because the noncovalent enzyme-inhibitor complex already inhibits the enzyme activity (rapid equilibrium approximation). Similarly, the value of initial velocity vi is equal to the uninhibited velocity vctrl in lieu of a rapid initial binding step, as can be observed for two-step (ir)reversible inhibitors at non-saturating concentrations ([I] << Kiapp) and one-step (ir)reversible inhibitors (vi < vctrl). Irreversible inhibitors are expected to reach 100% inhibition at reaction completion for all inhibitor concentrations, provided inhibitor is present in large excess and the reaction does not exceed the dynamic enzyme lifetime. Therefore, the final velocity vs is restrained to full inhibition (vs = 0) for two-step irreversible inhibitors (Data Analysis 1A) and one-step irreversible inhibitors (Data Analysis 1B). Two-step reversible inhibitors will reach a reversible steady-state equilibrium (vs ≥ 0) upon reaction completion (Data Analysis 1C). Be aware that the product formation progress curve is not only linear for fast-binding inhibitors but will also appear linear for slow-binding inhibitors if reaction completion is much slower than the time course of the assay (t << t½). Importantly, the noncovalent equilibrium is assumed to be reached instantly for two-step inhibitors (rapid equilibrium approximation). An algebraic solution to analyze irreversible two-step inhibitors violating the rapid equilibrium approximation is available as a preprint (Kuzmič, 2020a).

It is crucial to have linear product formation in the uninhibited control (F ctrl), as progress curve fitting for time-dependent (ir)reversible inhibition relies on the assumption that uninhibited product formation is absolutely linear. This ideal situation is often not feasible to achieve experimentally, as there are many factors contributing to a slight time-dependent decrease of product formation velocity in the uninhibited control, and not all of them are resolvable (common troubleshooting options are listed in Table 3 in the troubleshooting section near the end of the article). It is possible to correct algebraically. Algebraic correction for nonlinearity in the uninhibited control k ctrl caused by spontaneous enzyme degradation/denaturation is possible for irreversible inhibitors (Data Analysis 1A-B). Furthermore, it is also possible to perform an algebraic correction for substrate depletion for two-step irreversible inhibitors (Data Analysis 1D) (Kuzmič, Solowiej, & Murray, 2015). Ultimately, numerical integration is the preferred method in complex systems where multiple events contribute to the observed nonlinearity.

Basic Protocol 1: Progress Curve Analysis of Substrate Association Competition

The protocol below provides a generic set of steps to accomplishing this type of measurement. A practical example with specific reagents, and assay conditions for progress curve analysis of covalent Cathepsin K inhibitors can be found in Mons et al. (2019).

Materials

- 1× Assay/reaction buffer supplemented with co-factors and reducing agent

- Active enzyme, 4× solution in assay buffer

- Substrate with continuous read-out, 4× solution in assay buffer

- Positive control: vehicle/solvent as DMSO stock, or 2% solution in assay buffer

- Negative control: known inhibitor or alkylating agent as DMSO stock, or 2× solution in assay buffer

- Inhibitor: as DMSO stock, or serial dilution of 2× solution in assay buffer with 2% DMSO

- 384-well low volume microplate with nonbinding surface (e.g., Corning 3820 or 4513) for incubation and read-out

- Optical clear cover/seal (e.g., Perkin Elmer TopSeal-A Plus, #6050185, Corning 6575 Universal Optical Sealing Tape or Duck Brand HP260 Packing Tape)

- 1.5 ml (Eppendorf) microtubes to prepare stock solutions

- Optional : 96-well microplate to prepare serial dilution of inhibitor concentration

- Microplate reader equipped with appropriate filters to detect product formation (e.g., CLARIOstar microplate reader)

- Optional : Automated (acoustic) dispenser (e.g., Labcyte ECHO 550 Liquid Handler acoustic dispenser)

Before you start , optimize assay conditions in the uninhibited control to ensure compliance with assumptions and restrictions for progress curve analysis—most importantly linear product formation in the uninhibited control for the duration of the experiment (k ctrl = 0) — by activating the enzyme before reaction initiation (e.g., preincubation with reducing agent for proteases, or ATP for kinases and ligases), testing the enzyme activity on the (fluorogenic) substrate in absence of inhibitor, and adjusting the enzyme and substrate concentration ([S] 0>10[E]0) to reach maximum 10% substrate conversion at the end of the measurement window ([P]t < 0.1[S]0). Further optimization typically involves tuning the reader settings for optimal sensitivity, measurement of a calibration curve for product concentration (Dharadhar et al., 2019; Janssen et al., 2019), and calculation of the Z′-score from the uninhibited and inhibited controls (ideally 8 replicates) in a separate experiment (Zhang, Chung, & Oldenburg, 1999) to validate that enough product is formed for a good signal/noise ratio (Z′ > 0.5) at the end of the measurement. Consult Table 3 in the troubleshooting section near the end of the article for common optimization and troubleshooting options. The read-out of product formation must be homogeneous/continuous. Product formation of substrates with a less sensitive read-out (e.g., fluorescence polarization) may generate a relatively low product signal relative to the unprocessed substrate, and substrate depletion is unavoidable to generate a sufficient Z′-score (Zhang et al., 1999). Algebraic analysis of two-step irreversible inhibition with substrate depletion ([P]t < 0.1[S]0) can be performed with Data Analysis Protocol 1D after completion of Basic Protocol I , steps 2-6.

1.Add inhibitor or control to each well with the uninhibited control for full enzyme activity containing the same volume vehicle/solvent instead of inhibitor (we use DMSO in this protocol). Add a constant volume of serially diluted inhibitor in assay buffer supplemented with DMSO (e.g., 10.2 µl of 2× solution containing 2% DMSO), or add inhibitor and controls by (acoustic) dispensing of the pure DMSO stocks, with DMSO backfill to a constant volume (e.g., 0.2 µl), followed by addition of assay buffer to each well (e.g., 10 µl) and gentle shaking (300 rpm) to homogenize the solution.

Typically, measurements are performed in triplicate (or more replicates) with at least 8 inhibitor concentrations. Inhibitor concentrations might need optimization, but a good starting point is 0.1-10×IC50; the highest inhibitor concentration should correspond to maximum 90% initial (noncovalent) inhibition (vi > 0.1vctrl), as it can be difficult to accurately detect the increase from 90% to 100% inhibition.

2.Add substrate in assay buffer to each well (e.g., 5 µl of 4× solution) and homogenize the solutions by gentle shaking (300 rpm).

The order of substrate or inhibitor addition is not important per se , as long as enzyme is the last reagent to be added, and DMSO stocks are added prior to buffered (aqueous) solutions. Optionally, gently centrifuge the plate (1 min at 1000 rpm) to ensure that assay components are not stuck at the top of the well.

3.Add active enzyme in assay buffer to each well (e.g., 5 µl of 4× solution), with minimal delay between addition to the first and the last well. Optionally, gently centrifuge the plate (1 min at 1000 rpm) if bubbles are formed (especially for buffers containing surfactants), as these will induce assay artifacts, and to ensure assay components are in solution together rather than stuck to the wall at the top of the well.

Manual addition of enzyme solution and physically moving the plate to the plate reader introduces a delay that may slightly affect the accuracy of the measurement, as it can be variable (depending on the total number of wells, distance to the machine and walking pace of the researcher). This should not be significant if the delay is short compared to the total reaction time, but it can affect the outcome in the data analysis when t0 is actually 1-2 min. One method to monitor the delay between reaction initiation (onset of product formation and inhibition) and the start of product detection in step 6 is evaluation of the Y-intercept values (as discussed in Table 3). Alternatively, enzyme addition with an injector built into the plate reader minimizes the delay between reaction initiation (onset of product formation and inhibition) and starting the measurement.

4.Seal the wells by applying an optical clear cover.

Continuous kinetic measurements are subject to assay artifacts such as drift due to evaporation. In our experience, application of an optical clear cover/seal prior to measurement improves the assay robustness and resolves significant aberrant nonlinearity unrelated to enzyme activity.

5.Measure product formation in microplate reader by detection of the product read-out.

A typical assay measurement window is 60-240 min, with a measurement interval of 1-2 min. The inhibitor-binding reaction does not have to reach completion (100% inhibition for irreversible inhibitors, equilibrium for reversible inhibitors) within this window, but data will be more reliable when completion is reached before the end of the measurement (Fig. 5B).

6.Proceed to Basic Data Analysis Protocols to calculate the appropriate kinetic parameters for each covalent binding mode: Data Analysis Protocol 1A for two-step irreversible inhibitors, Data Analysis Protocol 1B for one-step irreversible inhibitors, Data Analysis Protocol 1C for two-step reversible inhibitors, or Data Analysis Protocol 1D for two-step irreversible inhibitors with substrate depletion.

| Data Analysis Protocol | |||

|---|---|---|---|

| EXP Conditions | 2-step IRREV | 1-step IRREV | 2-step REV |

| kctrl = 0 | 1A | 1B | 1C |

| kdegE > 0 | 1A | 1B | – |

| [P]t > 0.1[S]0 | 1D | – | – |

Exemplary assay concentrations.

| Concentration during incubation t | |||

|---|---|---|---|

| [stock] | V (µl) | [conc]t | |

| Enzyme | 4 nM | 5 | 0.99 nM |

| Inhibitor | 20 nM | 10.2 | 10.10 nM |

| Substrate | 4 µM | 5 | 0.99 µM |

| Total | 20.2 | ||

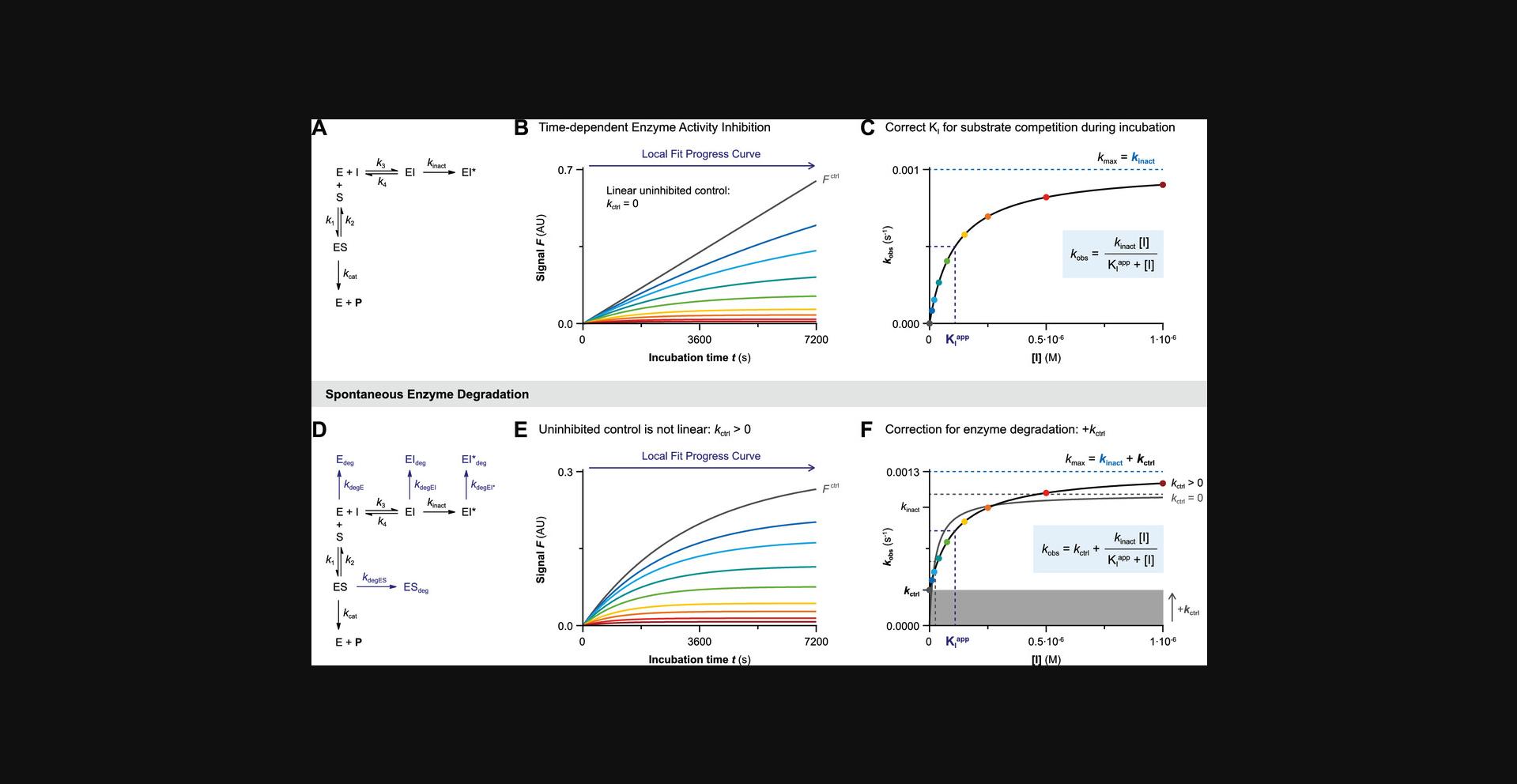

Data Analysis 1A: Progress Curve Analysis for Two-Step Irreversible Covalent Inhibition

The progress curve of time-dependent product formation of each inhibitor concentration is fitted to exponential Equation II (Fig. 5C) constraining final velocity to 100% inhibition (vs = 0) at reaction completion (Fig. 6A and 6B). The inhibitor concentration–dependent observed rate of inactivation k obs reflects the rate from initial velocity vi (rapid noncovalent equilibrium) to final velocity vs (inactivation at reaction completion). The plot of inhibitor concentration–dependent k obs reaches maximum rate of inactivation k inact in the presence of saturating inhibitor concentration ([I] >> KIapp) with the Y-intercept at 0 when the progress curve in absence of inhibitor is strictly linear (Fig. 6C). Importantly, the inhibitor concentration that results in half-maximum enzyme inactivation (k obs = ½× k inact) has to be corrected for competition by the substrate during incubation but maximum rate of inactivation k inact is unaffected.

Warnings and remarks

A linear plot of inhibitor concentration-dependent k obs (with Y-intercept = k ctrl) and an initial velocity independent of inhibitor concentration (vi = vctrl) are indicative of a one-step binding mechanism: the inhibitor concentration is not saturating ([I] ≤ 0.1KIapp and [I] ≤ 0.1Kiapp). This can be resolved by increasing the inhibitor concentration, reducing the substrate concentration, or processing the data with Basic Data Analysis Protocol 1B. Inhibitors with a high noncovalent potency ([I] >> Kiapp) might exhibit tight-binding behavior: complete inactivation is reached at reaction initiation (vi = 0), even at the lowest inhibitor concentration, without violating the pseudo-first order reaction conditions ([I]0 ≥ 10[E]0). This can be resolved by lowering the inhibitor concentration, but only if the assay robustness is sufficient to also lower the enzyme concentration, and/or by increasing the concentration of competing substrate, thus increasing the apparent inhibition constant Kiapp. Unfortunately, algebraic correction for progress curve analysis of one-step inhibitors (Copeland, 2013b) with inhibitor depletion ([I]0 < 10[E]0) is not compatible with two-step inhibition. Numeric fitting is a possibility to fit progress curves with depletion of substrate as well as inhibitor (Kuzmič, 2015). Alternatively, tight-binding two-step irreversible covalent inhibition can be assessed with Method IV if covalent adduct formation is relatively slow.

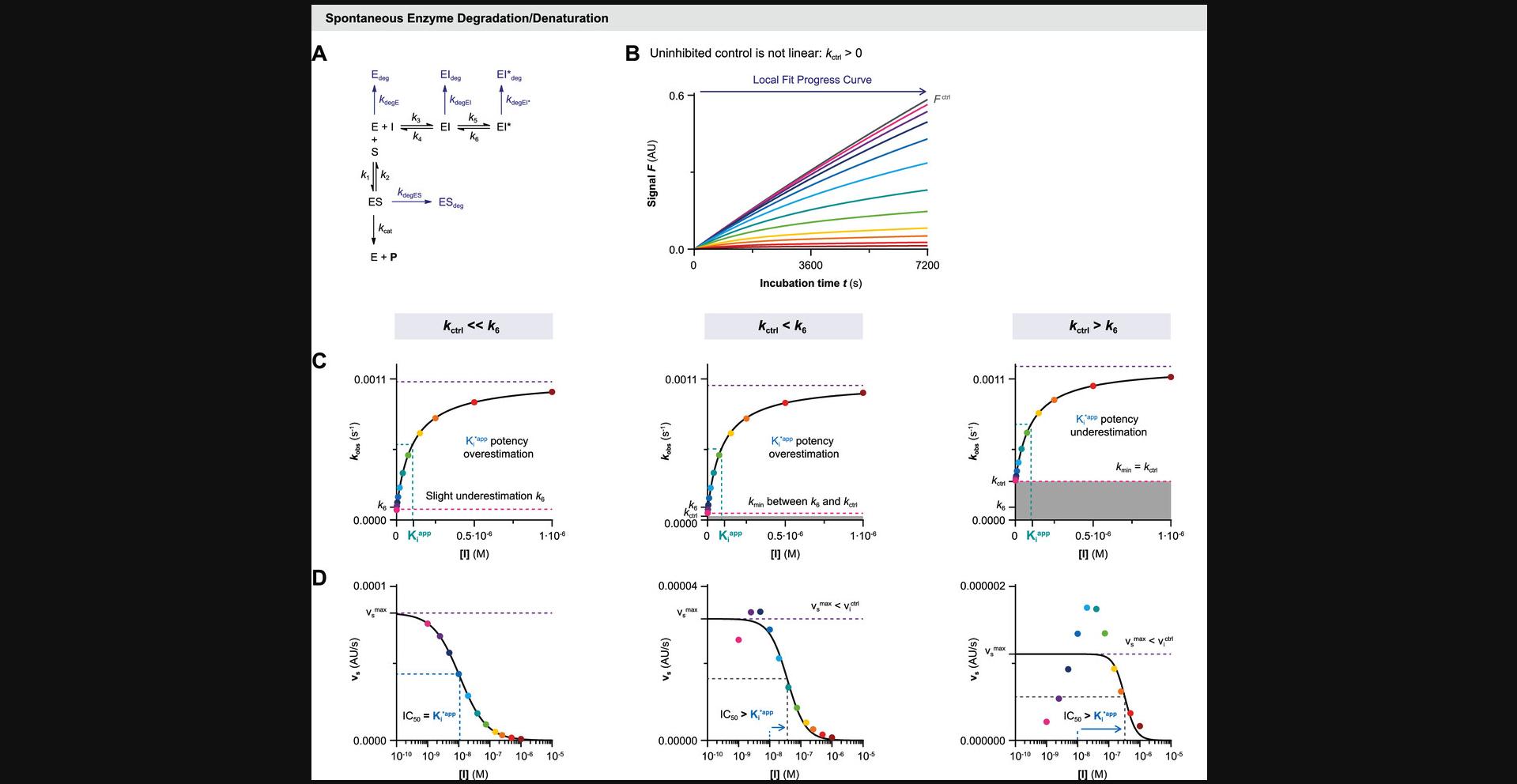

Spontaneous enzyme degradation/denaturation causes a nonlinearity in the uninhibited control (k ctrl > 0) that violates the assumption that time-dependence in the inhibitor-treated samples is a direct effect of the inhibitor (Fig. 6D and 6E). The first-order enzymatic degradation rate contributes to k obs independent of inhibitor concentration (k degE = k degES = k degEI). Consequently, the Y-intercept of the k obs against inhibitor concentration plot now corresponds to observed rate k ctrl in absence of inhibitor, and k max is higher (k max = k inact + k ctrl) (Fig. 6F). Performing a simple algebraic correction for the observed nonlinearity due to spontaneous enzyme degradation results in good estimates for k inact and KIapp (Fig. 6F). Ignoring the nonlinearity in the uninhibited control by restraining k ctrl = 0 implies that all time-dependent loss of enzyme activity should be attributed to inhibitor-mediated inactivation, resulting in an underestimation of inactivation constant KIapp (overestimation of potency) and overestimation of k inact. This effect is less pronounced when spontaneous enzyme degradation is much slower than the maximum rate of covalent adduct formation (k inact >> k ctrl). It is important to note that stabilization of the enzyme species by (noncovalent) inhibitor binding also decreases the contribution of k ctrl to the observed rate k obs at saturating inhibitor concentrations (k max = k inact). This impairs the accuracy of the algebraic correction unless k ctrl is relatively small (k max approaches k inact if k inact >> k ctrl).

This algebraic correction does not accurately correct for nonlinearity due to substrate depletion ([P]t > 0.1[S]0): substrate depletion is dependent on the total product formation and does not (significantly) contribute to k max at saturating inhibitor concentration because enzyme inhibition reduces the total amount of product formed (k max = k inact). Please consult Data Analysis 1D for algebraic correction of nonlinearity due to substrate depletion.

Basic Protocol 2: Two-Step Irreversible Covalent Inhibition

Processing of raw data obtained with Basic Protocol I for two-step irreversible covalent inhibitors.

1.Plot signal F against incubation time t.

Plot signal (in AU) on the Y-axis against incubation time (in s) on the X-axis for each inhibitor concentration and the controls (Fig. 6B). Product formation in the uninhibited control F ctrl should be linear. Consult Table 3 for troubleshooting of nonlinearity of the uninhibited control. Optionally, perform background correction to correct for assay artifacts such as bleaching and drift that cause a negative final velocity (vs < 0 AU/s) in the fully inhibited control. This correction can be subtraction of the background in presence of substrate (and inhibitor) but absence of enzyme, or subtraction of the fully inhibited control.

2.Fit signal F t against t to obtain k obs

Fit signal F t against incubation time t to Equation II (Fig. 6B/E). Constrain final velocity vs = 0 (in AU/s) for background-corrected product formation, or vs = value for full inhibition control. A lack of initial noncovalent complex (vi = vctrl) is indicative of one-step binding behavior.

\begin{equation} {F_{\rm {t}}} = ;{{\rm{v}}{\rm{s}}}t + \frac{{{{\rm{v}}{\rm{i}}} - {{\rm{v}}{\rm{s}}}}}{{{k{{\rm{obs}}}}}}\left[ {1 - {e^{ - {k_{{\rm{obs}}}}t}}} \right] + {F_0} \end{equation}

Equation II for nonlinear regression of user-defined explicit equation Y = (vsX) + (((vi-vs)/kobs)(1-EXP(-kobs*X))) + Y0 with Y = signal F t (in AU) and X = incubation time t (in s) to find Y0 = Y-intercept F 0 = background signal at t = 0 (in AU), vi = initial slope vi (in AU/s), vs = final slope vs (in AU/s) and kobs = observed reaction rate k obs (in s−1).

3.Plot k obs against [I].

Plot the mean and standard deviation of k obs (in s−1) on the Y-axis against inhibitor concentration (in M) after reaction initiation by enzyme addition (in the final solution) on the X-axis (Fig. 6C/F). The plot of k obs against [I] should reach a maximum k obs at saturating inhibitor concentration. Note that a linear curve is indicative of one-step binding behavior at non-saturating inhibitor concentrations ([I] << 0.1KIapp in Fig. 3F) with vi = vctrl (low initial inhibition). Proceed to Basic Data Analysis Protocol 1B , step 4, after it has been validated that the linear curve is not resultant from saturating inhibitor concentrations ([I] >> 10KIapp in Fig. 3G) as identified by vi << vctrl (significant initial inhibition), by repeating the measurement with a higher competitive substrate concentration (increase KIapp) and/or lower inhibitor concentration.

4.Fit k obs against [I] to obtain k inact and KIapp.

Fit k obs against inhibitor concentration to Equation VII to obtain maximum inactivation rate constant k inact (in s−1) and apparent inactivation constant KIapp (in M). Constrain k ctrl = k obs of the uninhibited control (Fig. 6F). Calculate inactivation constant KI (in M) and irreversible covalent inhibitor potency k inact/KI (in M−1s−1) with Sample Calculation 1 &2.

\begin{equation} {k_{{\rm{obs}}}} = {k_{{\rm{ctrl}}}} + \frac{{{k_{{\rm{inact}}}}\left[ {\rm{I}} \right]}}{{{{\rm{K}}_{\rm{I}}}^{{\rm{app}}} + \left[ {\rm{I}} \right]}} \end{equation}

Equation VII for nonlinear regression of user-defined explicit equation Y = Y0 + ((kmax*X)/((KIapp) + X)) with Y = observed reaction rate k obs (in s−1) and X = inhibitor concentration (in M) to find Y0 = rate of nonlinearity in uninhibited control k ctrl (in s−1), kmax = maximum reaction rate k inact (in s−1) and KIapp = Apparent inactivation constant KIapp (in M).

5.EXTRA: Plot and fit vi against [I] to obtain Kiapp.

Inhibition constant Ki can be calculated from the initial velocity vi (obtained in step 3), reflecting the rapid (initial) noncovalent enzyme-inhibitor equilibrium. Plot the mean and standard deviation of vi (in AU/s) on the Y-axis against inhibitor concentration on the X-axis (similar to Fig. 8D). Fit vi against [I] to four-parameter nonlinear regression Hill Equation VIII (Copeland, 2013e) to obtain apparent inhibition constant Kiapp (in M). Constrain the top to the uninhibited vi (maximum velocity = vctrl) and the bottom to the fully inhibited vi (vimin = minimum velocity. For (background-)corrected product formation vimin = 0). Calculate inhibition constant Ki (in M) with Sample Calculation 3.

\begin{equation} {{\rm{v}}{\rm{i}}} = {\rm{v}}{\rm{i}}^{{\rm{min}}} + \frac{{{{\rm{v}}^{{\rm{ctrl}}}} - {\rm{v}}{\rm{i}}^{{\rm{min}}}}}{{1 + {{\left( {\frac{{\left[ {\rm{I}} \right]}}{{{{\rm{K}}{\rm{i}}}^{{\rm{app}}}}}} \right)}^h}}} \end{equation}

Equation VIII for nonlinear regression of four-parameter dose-response equation Y = Bottom + (Top-Bottom)/(1 + (X/IC50)^HillSlope) with Y = initial product formation velocity vi (in AU/s), X = inhibitor concentration (in M), Bottom = velocity in fully inhibited control vimin (in AU/s), and Top = maximum velocity in uninhibited control vctrl (in AU/s) to find Hillslope = Hill coefficient h (unitless) and IC50 = apparent inhibition constant Kiapp (in M).

6.Optional : Validate experimental kinetic parameters with kinetic simulations.

Proceed to Kinetic Simulations 1 to compare the experimental progress curves to the progress curves simulated with scripts KinGen and KinDeg (using experimental rate constant k inact = k 5) to confirm that the calculated kinetic constants are in accordance with the experimental data.

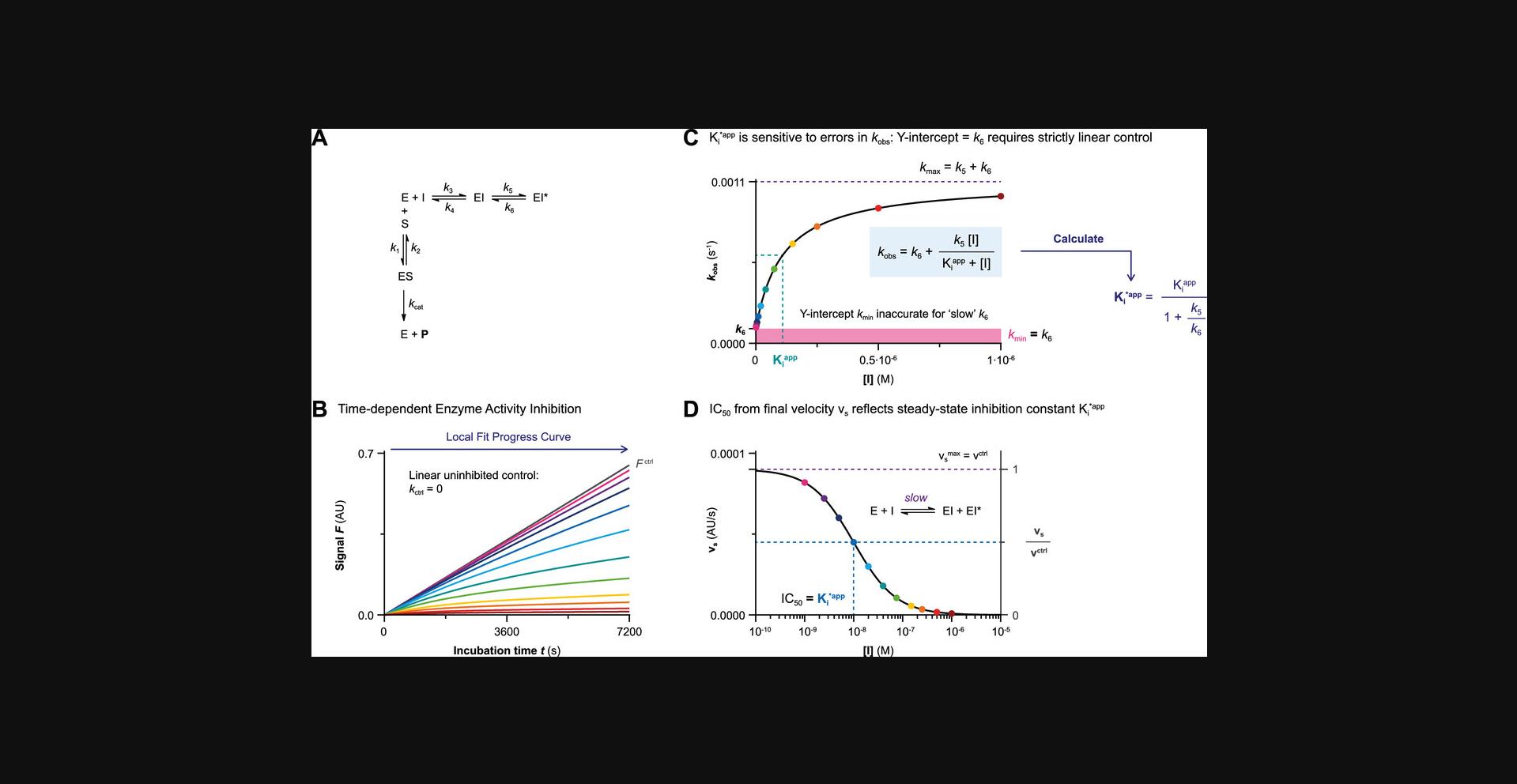

Data Analysis 1B: Progress Curve Analysis for One-Step Irreversible Covalent Inhibition

The progress curve of time-dependent product formation of each inhibitor concentration is fitted to exponential Equation II (Fig. 5C) constraining final velocity to inactivation (vs = 0) at reaction completion (Fig. 7A and 7B). The initial velocity vi equals the uninhibited product formation velocity (vi = vctrl), as noncovalent inhibitor binding does not contribute to enzyme inhibition by one-step irreversible inhibitors. A linear plot of inhibitor concentration–dependent k obs is indicative of a one-step binding mechanism with k chemapp as the slope (Fig. 7C). Two-step irreversible covalent inhibitors also have a linear k obs against inhibitor concentration plot at non-saturating concentrations ([I] ≤ 0.1KIapp) with k chemapp = k inact/KIapp.

![Details are in the caption following the image Data Analysis 1B: Progress curve analysis for one-step irreversible covalent inhibition. Simulated with KinGen (A-C) or KinDeg (D-F) for inhibitor D with 1 pM enzyme and 100 nM substrate S1. (A) Schematic enzyme dynamics during incubation for one-step irreversible covalent inhibition. (B) Time-dependent product formation in absence of inhibitor F<sup>ctrl</sup> or in presence of inhibitor. The progress curve for each inhibitor concentration is fitted individually to Equation II (Fig. 5C) (constraining v<sub>s</sub> = 0) to obtain the observed rate of inactivation k<sub>obs</sub>. v<sub>i</sub> = v<sup>ctrl</sup> for one-step irreversible inhibitors and two-step irreversible inhibitors at non-saturating concentrations ([I] << K<sub>i</sub><sup>app</sup>). (C) Inhibitor concentration–dependent k<sub>obs</sub> increases linearly with inhibitor concentration, with k<sub>chem</sub><sup>app</sup> as the slope. (D) Schematic enzyme dynamics during incubation for one-step irreversible covalent inhibition with spontaneous loss of enzyme activity. Simulated with k<sub>degE</sub> = k<sub>degES</sub> = k<sub>degEI</sub> = 0.0003 s<sup>−1</sup>. (E) Time-dependent product formation in absence of inhibitor F<sup>ctrl</sup> is not linear because k<sub>ctrl</sub> > 0. The progress curves for each inhibitor concentration and uninhibited control are fitted individually to Equation II (Fig. 5C) (constraining v<sub>s</sub> = 0) to obtain the observed rates of inactivation k<sub>obs</sub>. (F) Inhibitor concentration–dependent k<sub>obs</sub> with spontaneous enzyme degradation/denaturation increases by k<sub>ctrl</sub>. Fit with algebraic correction for nonlinearity (black line, k<sub>ctrl</sub> > 0) or ignoring nonlinearity (gray line, constrain k<sub>ctrl</sub> = 0). Ignoring the nonlinearity (assuming Y-intercept = 0) results in overestimation of k<sub>chem</sub><sup>app</sup> (steeper slope).](https://static.yanyin.tech/literature_test/cpz1419-fig-0007-m.jpg)

Warnings and remarks

The slope has to be corrected for substrate competition to obtain the inactivation constant k chem (in M−1s−1). Substrate will occupy a fraction of the unbound enzyme to reach the noncovalent E + S <-> ES equilibrium (how much depends on [S]/KM), thus reducing the unbound enzyme concentration. It may seem counterintuitive to correct for substrate competition, as the pseudo-first-order rate of covalent adduct formation (k obs = k chemapp[I]) does not seem to involve unbound enzyme (provided inhibitor is present in large excess), but formation of EI* is limited by the available unbound enzyme at that moment and it is not possible to form covalent adduct EI* when competing substrate blocks access to the enzyme active site.

It is important to have linear product formation in the uninhibited control (k ctrl = 0) or to perform an algebraic correction for nonlinearity in the uninhibited control (k ctrl > 0) caused by spontaneous first-order enzyme degradation/denaturation (Fig. 7D-F). Failure to correct for the contribution of enzyme degradation when fitting the observed rate of inactivation k obs against inhibitor results in overestimation of k chemapp (Fig. 7F, gray line). The contribution of nonlinearity k ctrl becomes less pronounced at elevated inhibitor concentrations as k ctrl becomes significantly smaller than k obs (k ctrl << k chemapp[I]). (De)stabilization of enzyme upon inhibitor binding (k degEI*) does not affect k obs, as EI* formation is already irreversible, thus removing the species from the available pool of catalytic enzyme. To our knowledge, methods to algebraically correct for substrate depletion have not been reported.

Basic Protocol 3: One-Step Irreversible Covalent Inhibition

Processing of raw data obtained with Basic Protocol I for one-step irreversible covalent inhibitors and two-step irreversible inhibitors at non-saturating inhibitor concentrations ([I] ≤ 0.1Kiapp).

1.Plot signal F against incubation time t.