Assays to Study Enzymatic and Non-Enzymatic Protein Lysine Acetylation In Vitro

Leonie G. Graf, Leonie G. Graf, Robert Vogt, Robert Vogt, Anna-Theresa Blasl, Anna-Theresa Blasl, Chuan Qin, Chuan Qin, Sabrina Schulze, Sabrina Schulze, Daniela Zühlke, Daniela Zühlke, Susanne Sievers, Susanne Sievers, Michael Lammers, Michael Lammers

Abstract

Proteins can be lysine-acetylated both enzymatically, by lysine acetyltransferases (KATs), and non-enzymatically, by acetyl-CoA and/or acetyl-phosphate. Such modification can be reversed by lysine deacetylases classified as NAD+-dependent sirtuins or by classical Zn2+-dependent deacetylases (KDACs). The regulation of protein lysine acetylation events by KATs and sirtuins/KDACs, or by non-enzymatic processes, is often assessed only indirectly by mass spectrometry or by mutational studies in cells. Mutational approaches to study lysine acetylation are limited, as these often poorly mimic lysine acetylation. Here, we describe protocols to assess the direct regulation of protein lysine acetylation by both sirtuins/KDACs and KATs, as well as non-enzymatically. We first describe a protocol for the production of site-specific lysine-acetylated proteins using a synthetic biological approach, the genetic code expansion concept (GCEC). These natively folded, lysine-acetylated proteins can then be used as direct substrates for sirtuins and KDACs. This approach addresses various limitations encountered with other methods. First, results from sirtuin/KDAC-catalyzed deacetylation assays obtained using acetylated peptides as substrates can vary considerably compared to experiments using natively folded substrate proteins. In addition, producing lysine-acetylated proteins for deacetylation assays by using recombinantly expressed KATs is difficult, as these often do not yield proteins that are homogeneously and quantitatively lysine acetylated. Moreover, KATs are often huge multi-domain proteins, which are difficult to recombinantly express and purify in soluble form. We also describe protocols to study the direct regulation of protein lysine acetylation, both enzymatically, by sirtuins/KDACs and KATs, and non-enzymatically, by acetyl-CoA and/or acetyl-phosphate. The latter protocol also includes a section that explains how specific lysine acetylation sites can be detected by liquid chromatography coupled to tandem mass spectrometry (LC-MS/MS). The protocols described here can be useful for providing a more detailed understanding of the enzymatic and non-enzymatic regulation of lysine acetylation sites, an important aspect to judge their physiological significance. © 2021 The Authors. Current Protocols published by Wiley Periodicals LLC.

Basic Protocol 1 : Preparation of N-(ε)-lysine-acetylated proteins using the genetic code expansion concept (GCEC)

Basic Protocol 2 : In vitro sirtuin (SIRT)-catalyzed deacetylation of lysine-acetylated proteins prepared by the GCEC

Basic Protocol 3 : In vitro KDAC/HDAC-catalyzed deacetylation of lysine-acetylated proteins

Basic Protocol 4 : In vitro lysine acetylation of recombinantly expressed proteins by lysine acetyltransferases (KATs)

Basic Protocol 5 : In vitro non-enzymatic lysine acetylation of proteins by acetyl-CoA and/or acetyl-phosphate

INTRODUCTION

Lysine acetylation is a post-translational modification that was originally found in the 1960s in histones, affecting RNA synthesis (Allfrey, Faulkner, & Mirsky, 1964; Phillips, 1963). Today, it is known that lysine acetylation is present in thousands of proteins in organisms of all domains of life, regulating fundamental cellular processes (Choudhary et al., 2009; Lundby et al., 2012; Weinert et al., 2011). A dysfunction in the post-translational machinery responsible for this modification is associated with the development of severe diseases in humans, ranging from neurodegenerative disorders and cancer to metabolic diseases. Moreover, it is directly involved in the aging process of organisms (Imai & Guarente, 2016; Zullo, Simone, Grimaldi, Musto, & Mancini, 2018). Identifying proteins subjected to this modification and understanding its regulation, is, thus, of significant relevance.

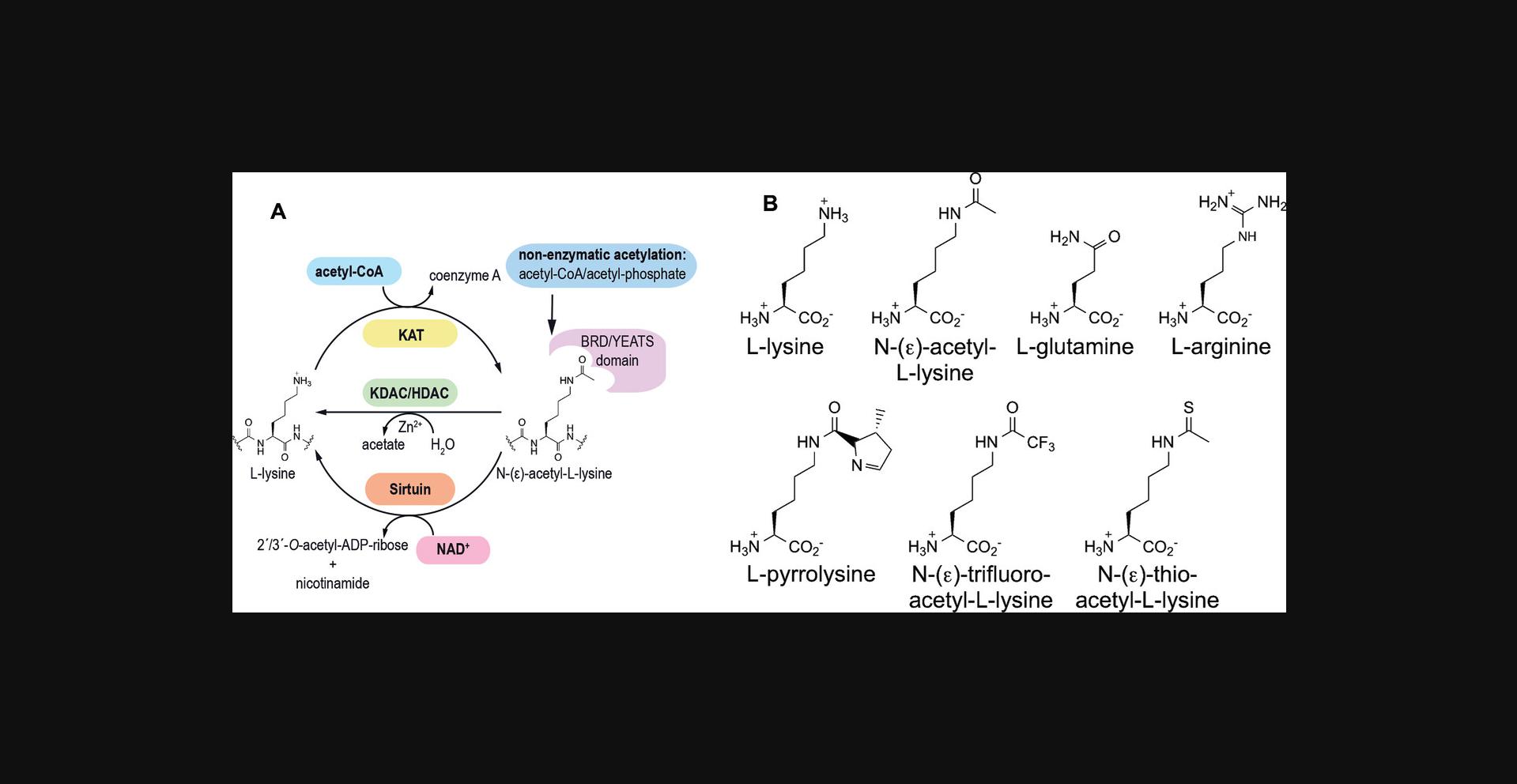

Lysine acetylation is tightly connected to the cellular metabolic state, as lysine acetyltransferases, enzymes that catalyze protein lysine acetylation, use the central metabolic molecule acetyl-CoA as donor molecule for the acetylation of the ε-amino group of lysine side chains, and sirtuins (SIRT: silent information regulator), the corresponding deacetylases, use NAD+ as a stoichiometric co-substrate for catalysis (Fig. 1A; Albaugh, Arnold, & Denu, 2011; Dittenhafer-Reed, Feldman, & Denu, 2011; Feldman, Dittenhafer-Reed, & Denu, 2012; Schmidt, Smith, Jackson, & Denu, 2004). In addition to enzymatic acetylation, non-enzymatic acetylation has been described in eukaryotes and prokaryotes (Dieterich et al., 2019; Weinert et al., 2013). The level of non-enzymatic acetylation depends on the concentration of the high-energy molecules acetyl-CoA and acetyl-phosphate, the major drivers of non-enzymatic acetylation in eukaryotes and in bacteria, respectively, (Kuhn et al., 2014; Weinert et al., 2013; Fig. 1A). Notably, recent reports suggest that non-enzymatic, chemical acetylation can even occur in a site-specific manner, and protein sequence and structure might affect its efficiency (Baeza, Smallegan, & Denu, 2015; Chen & Li, 2019; Lindahl, Lawton, Baeza, Dowell, & Denu, 2019; Wang, You, & Ye, 2017; Fig. 1A).

The massive progress in mass spectrometry (MS) in the last two decades has enabled the identification of thousands of lysine acetylation sites in proteins from organisms of all domains of life (Baeza et al., 2014; Baeza et al., 2020; Choudhary et al., 2009; Choudhary, Weinert, Nishida, Verdin, & Mann, 2014; Thomas, Haws, Borth, & Denu, 2020; Weinert et al., 2015; Weinert et al., 2018; Weinert et al., 2011). Importantly, however, these experiments have limitations in assessing whether acetyl transfer events are direct or indirect with regard to an enzyme-substrate connection. Follow-up experiments with purified materials are needed to complement such genetic studies.

Other reported methods to identify KAT/KDAC/sirtuin substrates employ acetylated peptides or microarrays consisting of small acetylated/non-acetylated peptides spotted on a surface (Rauh et al., 2013; Schutkowski, Fischer, Roessler, & Steegborn, 2014). These experiments assume that the primary sequence is the major molecular determinant of substrate specificity, and do not take into account that the three-dimensional structure of the protein can have a profound effect on the recognition of an individual acetylation site by lysine deacetylases. We have shown, by using natively folded proteins that have been site-specifically lysine acetylated as substrates, that the protein structure is a major factor determining substrate specificity for sirtuins and acetyltransferases (Knyphausen et al., 2016). Again, it is important to then validate sites identified by these microarray methods in follow-up experiments and to evaluate the contribution of protein structure and, ultimately, the physiological importance of these sites.

Several laboratories have performed mutational studies not only in vivo , in mammalian cells, but also in vitro , using recombinantly expressed and purified proteins, to derive the role of lysine acetylation and its consequences on protein function. Mutation of lysine to glutamine (Lys to Gln) is often used in these studies as a mimic for acetyl lysine, and mutation of lysine to arginine (Lys to Arg) is typically used to conserve the non-acetylated state (Fig. 1B). However, from a chemical perspective, the structural mimicry of acetyl-lysine (AcK) by Gln and that of Lys by Arg is rather crude in terms of sterics and physicochemical properties (Fig. 1B; de Boor et al., 2015; Knyphausen, Lang, Baldus, Extra, & Lammers, 2016). In fact, it has been shown that mutation of Lys to Gln is often a poor mimic of lysine acetylation at the molecular level. Apart from these points, recruitment of a lysine-acetylated protein to a reader domain [bromodomain (BRD), YEATS domain] is not captured by these mutations (Fig. 1B). Moreover, it is not clear if these mutations can mimic crosstalk of lysine acetylation with other post-translational modifications. These examples demonstrate that it is important to show the reliability of using these mutations to study lysine acetylation, particularly in cellular studies, in order to draw valid conclusions from the experiments and not misinterpret the results and the physiological consequences of a lysine-acetylation event.

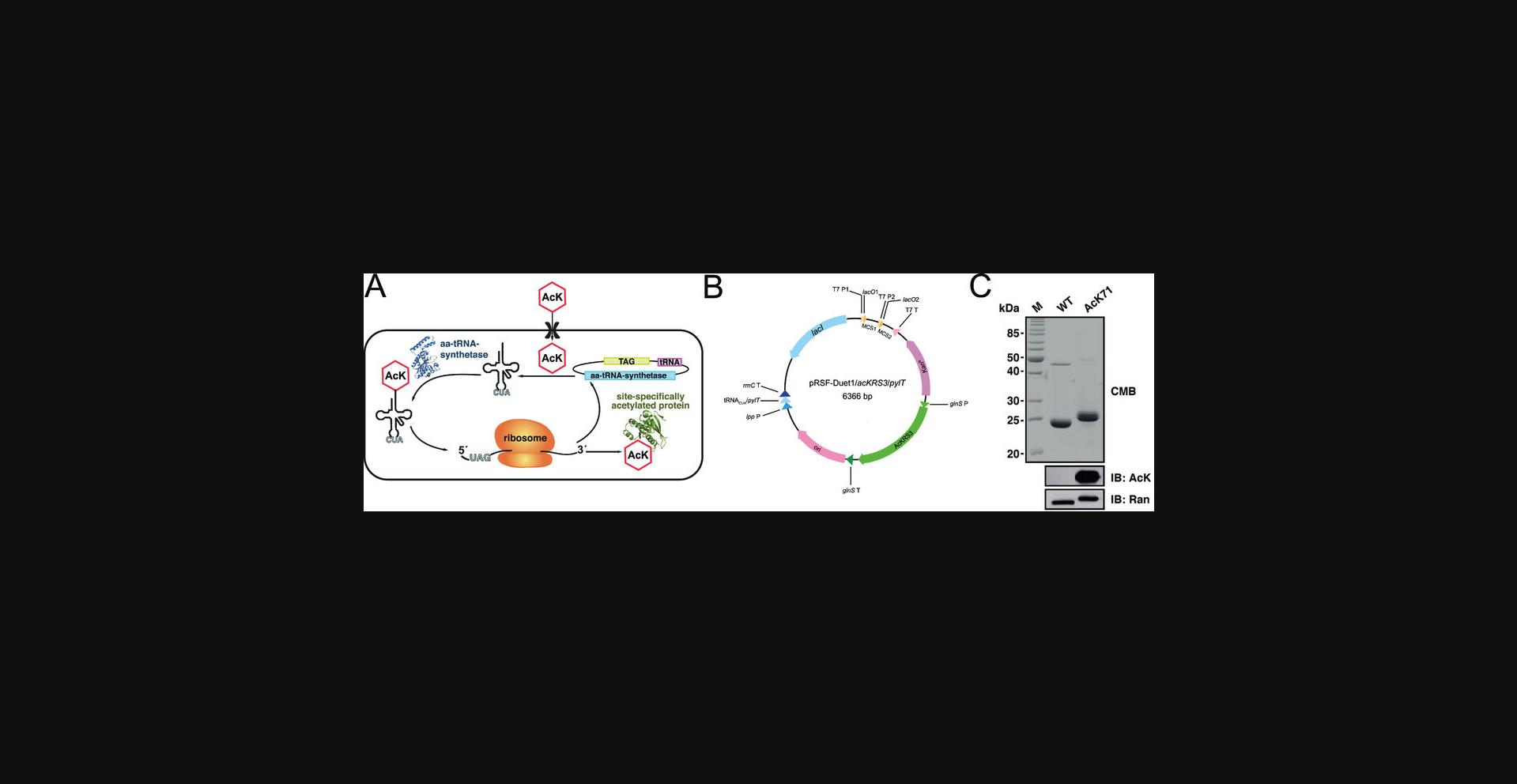

A major step in the field was the development of the genetic code expansion concept (GCEC), which enables the study of the real consequences of a site-specific lysine acetylation in a protein, in its natively folded state (Kuhlmann et al., 2016; Lammers, 2018; Lammers, Neumann, Chin, & James, 2010; Neumann, Peak-Chew, & Chin, 2008). This system is based on a synthetically evolved orthogonal acetyl-lysyl-tRNA-synthetase (AcKRS3)/tRNACUA (PylT)-pair originating from pyrrolysyl-tRNA-synthetase (PylRS) from methanogenic archaea of the genus Methanosarcina. We have used the acetyl-lysyl-tRNA-synthetase/tRNACUA pair from M. barkeri to prepare proteins that are homogenously, site-specifically, and quantitatively lysine acetylated. Moreover, the proteins used in this system are natively folded, which is a major advantage in studying the role of lysine acetylation in regulating protein function compared to acetylated peptides, which often do not represent the correct three-dimensional structural context. The AcKRS3/PylT pair from M. barkeri has been shown to be orthogonal in all model organisms, i.e., it does not interfere with the endogenous translation system. AcKRS3 charges the cognate tRNA PylT with acetyl-L-lysine, and this can thereby be co-translationally incorporated into proteins in response to an amber stop codon, using the endogenous cellular translational machinery.

Here, we describe protocols that help address some of the limitations explained above to directly study the regulation of protein lysine acetylation, both enzymatically, by sirtuins/KDACs as well as KATs, and non-enzymatically, by acetyl-CoA and acetyl-phosphate. These include a protocol for producing a protein that is natively folded and site-specifically and homogenously lysine-acetylated via the GCEC, in yields and quality compatible with biophysical studies, including X-ray crystallography (Basic Protocol 1; Fig. 2A). The precise lysine acetylation afforded by this approach permits a more accurate determination of its potential regulatory roles. Moreover, genetic incorporation of acetyl lysine allows the investigator to assess the real consequences of a protein lysine-acetylation event, rather than using Lys to Gln or Lys to Arg mutants as it is often done in cell culture experiments.

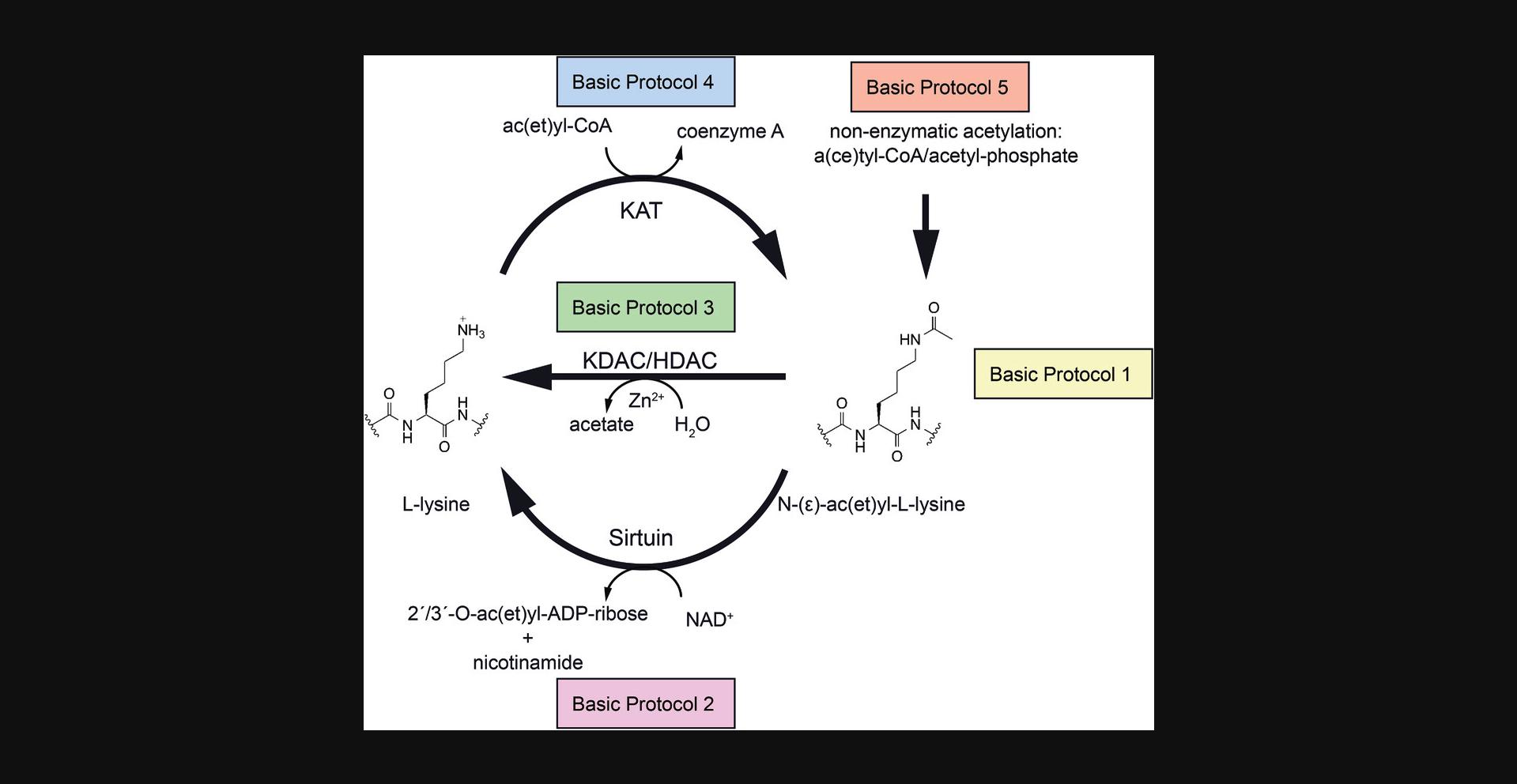

While most mass spectrometry−based data on KDACs/sirtuins, KATs, and non-enzymatic acetylation driven by acetyl-phosphate/acetyl-CoA do not reveal direct substrates, recombinantly expressed and purified acetylated and non-acetylated proteins are often used to identify direct targets of these enzymatic and non-enzymatic reactions. Knowledge about the regulation of an individual acetylation event is important to judge its cellular spatial and temporal coordination, as well as its physiological significance. We thus describe protocols for using site-specifically acetylated proteins as substrates for sirtuins, allowing the characterization of deacetylation reactions catalyzed by these enzymes (Basic Protocol 2). Moreover, this allows studying enzyme activities in their natural sequence and structural context rather than using reporter peptides, such as Fluor-de-Lys peptides, which are mostly histone-derived or p53-derived peptides. We also describe a protocol that includes preparation of acetylated proteins to then study the deacetylation catalyzed by classical deacetylases (Basic Protocol 3). To complete the assessment of the lysine acetylation cycle, we also describe the preparation of non-acetylated proteins to study their acetylation, both enzymatically, by lysine acetyltransferases (Basic Protocol 4), and non-enzymatically, by acetyl-CoA and/or acetyl-phosphate (Basic Protocol 5). In combination with LC-MS/MS analyses, this facilitates the direct identification of individual lysine substrate sites in proteins. An overview of the protocols described in this article is shown in Figure 3.

Overall, these protocols aim to allow users to gain a comprehensive understanding of the regulation of lysine acetylation of a protein, both enzymatically and non-enzymatically, to judge the physiological significance of an individual lysine acetylation site.

Strategic Planning

For the preparation of site-specifically lysine-acetylated proteins using the GCEC, the gene encoding the desired protein of interest (POI) carrying an amber stop codon (POIUAG) must first be cloned into an expression plasmid. Either the expression is performed using a one-plasmid system—encoding for the protein of interest, the Methanosarcina barkeri acetyl-lysyl-tRNA synthetase (AcKRS3), and the Mb tRNACUA (Fig. 2B)—or a two-plasmid one. In the latter case, the coding region of the protein of interest can be cloned together with the Mb tRNACUA, including the promoter and terminator regions, in one plasmid, and the coding region for acyl-lysyl-tRNA synthetase, including promoter and terminator regions, can be cloned in another plasmid. We constructed a vector based on pRSF-Duet1 that encodes for the synthetically evolved acetyl-lysyl-tRNA-synthetase(AcKRS3)/Mb tRNACUA (PylT)-pair from Methanosarcina barkeri next to the protein of interest (Fig. 2B). Here, the expression of acKRS3 is under the control of a constitutive glutaminyl-tRNA-synthetase promotor (glnS P) and terminator (glnS T), and pylT expression is under control of a constitutive lipoprotein (lpp)-promotor and rrnC terminator (Fig. 2B; Lammers, 2018). In pRSF-Duet1, the gene of interest is expressed under the control of a T7 promotor (T7 P) and T7 terminator (T7 T). This allows inducing expression by adding IPTG. Importantly, the origins of replication of both plasmids should belong to different incompatibility groups, and they should contain genes encoding for different antibiotic resistances, to allow propagation and maintenance in E. coli.

For the other protein purification protocols described here, appropriate expression constructs must be prepared beforehand. The choice of the expression plasmid depends on several factors such as solubility of the target protein and compatibility with buffer components needed for the purification, such as imidazole, which is needed for elution of a His6-tagged protein. Small-scale tests can be performed in advance to define the optimal expression and purification conditions before applying the GCEC to initiate expression and purification of the acetylated protein. Optimization parameters should include: expression host, expression temperature and duration, IPTG concentration, method used for cell lysis (sonication, French press, microfluidics, lysozyme, etc.), the buffer system, and further buffer components used for resuspension and for purification and optimization of the purification strategy. The purification of proteins should be conducted as quickly as possible in a continuous process to ensure that unstable proteins do not precipitate during the process. Proteins should be shock-frozen in liquid nitrogen in small aliquots to avoid repeated freeze-thaw cycles, and then stored long-term at −80°C. The optimal purification conditions, including purification affinity tags, buffer components, and buffer pH, should be analyzed carefully to obtain properly folded proteins in high yield. In that context, it is also recommended to analyze if codon optimization for E. coli expression results in an increase in the yield of soluble protein. In our experience, this can increase the amount of soluble target protein. Several companies offer the synthesis of codon-optimized genes for expression in various expression hosts.

For the purification of the classical Zn2+-dependent KDACs (Basic Protocol 3), prepare a Zn2+-charged Zn2+-NTA-column in advance. To this end, connect an Ni2+-NTA column to an automated FPLC system. Strip the column with 2 column volumes (CVs) of 0.1 M EDTA, wash with 10 CVs of water, recharge the column with 3 CVs of 0.1 M ZnCl2 solution, and wash again with 5 CVs of water before equilibrating it with KDAC lysis buffer.

To select the correct size-exclusion chromatography (SEC) column type for the purification of the target protein on a preparative scale, perform analytical SEC runs beforehand. These analytical SEC analyses can be performed on different columns (S200 Increase 10/300 GL, S75 Increase 10/300 GL, Superose 6 Increase 10/300 GL) to determine the elution volume and the oligomeric state of the target protein.

Basic Protocol 1: PREPARATION OF N-(ε)-LYSINE-ACETYLATED PROTEINS USING THE GENETIC CODE EXPANSION CONCEPT (GCEC)

This protocol describes the generation of site-specifically acetylated proteins that can be used as substrates for deacetylases to analyze deacetylation by sirtuin deacetylases and/or classical deacetylases (KDACs). To generate site-specifically lysine-acetylated proteins, the genetic code expansion concept (GCEC) represents a powerful tool. The GCEC is based on a synthetically evolved orthogonal acetyl-lysyl-tRNA-synthetase (AcKRS3)/tRNACUA pair derived from the pyrrolysyl-tRNA-synthetase (PylRS)/tRNACUA (PylT) pair from an archaea of the genus Methanosarcina. Here, as an example, we describe the site-specific lysine acetylation of the small GTP-binding protein Ran at Lys71 (Ran AcK71), applying the GCEC (Fig. 2A), using a one-plasmid system. The application of the GCEC allows the production of site-specifically and quantitatively lysine-acetylated proteins, which are natively folded (Knyphausen et al., 2016; Lammers, 2018). These natively folded proteins can then be used to study sirtuin- (Basic Protocol 2) and KDAC-catalyzed (Basic Protocol 3) deacetylation.

Materials

-

Competent E. coli BL21 (DE3) cells (Novagen®; Sigma-Aldrich, cat. no: 69450)

-

Plasmid pRSF-Duet1 (Sigma-Aldrich, cat. no.: 71341) expressing ackRS3 /MbpylT/ranUAG71 (see Strategic Planning)

-

Lysogeny broth (LB) agar plates (see recipe) containing 50 µg ml-1 kanamycin

-

Lysogeny broth (LB) medium (sterilize by autoclaving) (see recipe)

-

Kanamycin sulfate (50 mg ml-1 stock in H2O; Carl Roth, CAS no. 25389-94-0)

-

1 M N-(ε)-acetyl-L-lysine (Chem-Impex Int.; CAS no. 692-04-6, cat. no. 05364) in sterile-filtered (0.22-µm filter) deionized water (prepare fresh)

-

2 M nicotinamide (Sigma-Aldrich; CAS no. 98-92-0, cat. no. N3376) in sterile-filtered (0.22-µm filter) deionized water (prepare fresh)

-

Isopropyl β-D-1-thiogalactopyranoside (IPTG; 1 M stock in H2O; Carl Roth, CAS no. 367-93-1)

-

Buffers 1.1, 1.2, 1.3, 1.4, and 1.5 (see recipes)

-

Liquid nitrogen (CAUTION : handle with care; use protective equipment for extremely low temperatures and provide a well-ventilated environment)

-

5× SDS-PAGE sample buffer (see recipe)

-

12% v/v SDS-PAGE gel (see recipe)

-

SDS-PAGE running buffer (see recipe)

-

SDS-PAGE staining solution (see recipe)

-

SDS-PAGE destaining solution (see recipe)

-

100-ml and 5-L baffled Erlenmeyer flasks (VWR, cat. no. 214-1131 and 214-1137)

-

Incubator (e.g., Function Line B20; Heraeus Holding GmbH)

-

Shaking incubator (e.g., Infors HT Multitron Standard; Infors AG)

-

UV/Vis spectrophotometer (e.g., Varian Cary 50 UV-Vis spectrophotometer or NanoDrop ND 1000, VWR International GmbH)

-

Heat block (e.g., Mixing Block MB-102, Bioer Technology Co.; and Digital Heatblock, VWR International GmbH)

-

Refrigerated microcentrifuge

-

Centrifuge (e.g., SORVALL RC 6 with Rotor SLA-1500 and Rotor SS-34, Thermo Fisher GmbH)

-

250-ml glass beaker (VWR, cat. no. 213-1121)

-

Sonicator [e.g., Sonopulse HD 4100 with UW 100, TS133V, SH 100G, and tip TT213 (ᴓ12.7 mm); BANDELIN Electronic GmbH & Co. KG, Berlin, Germany]

-

5-ml HisTrapTM FF crude column (Cytiva, cat. no. 17-5286-01)

-

Automated FPLC system and fraction collector (Cytiva, Bio-Rad)

-

Sterile bottle-top filters, 0.45-μm pore size

-

Electrophoresis chamber and power supply (e.g., Bio-Rad Laboratories GmbH)

-

Amicon® Ultra-15 centrifugal filter unit (10 kDa MW cut off; Merck, cat. no. UFC901024)

-

Black Corning® 96-well plate with flat bottom

-

Preparative size-exclusion column: HiLoad® 26/60 Superdex®75 pg column (Cytiva, cat. no. 28-9893-34)

-

Medium-pressure chromatography system (low MPA range) with UV detection (280 nm) (e.g., Äkta Purifier, GE Healthcare) and a fraction collector

-

Nitrocellulose/PVDF membrane (Carl Roth GmbH & Co. KG)

-

Semi-dry Blotter Trans-Blot® TurboTM Transfer System (e.g., Bio-Rad Laboratories GmbH)

-

Chemiluminescent detection system (e.g., Octoplus QUPLEX, Intas Science Imaging Instruments GmbH)

-

1.5-ml microtubes (BRAND, cat. no. 780500)

-

Additional reagents and equipment for SDS-PAGE (see Current Protocols article: Gallagher, 2012) and immunoblotting (Western blotting; Ni, Xu, & Gallagher, 2016)

Expression of His6-Ran AcK71

1.Transform E. coli (BL21) DE3 cells with pRSFDuet-1/ackRS3 /MbpylT/ranUAG71

2.Plate cells on selective LB agar plates containing 50 µg ml-1 kanamycin and incubate the plates overnight at 37°C.

3.Add 25 ml of LB medium containing 50 µg ml-1 kanamycin to a 100-ml baffled Erlenmeyer flask. Inoculate this pre-culture with four to five single colonies from the LB agar plate from step 2.Incubate the pre-culture overnight (∼16 hr, 37°C, and 160 rpm)

4.Prepare eight 5-L baffled Erlenmeyer flasks, each with 1.25 L of LB medium supplemented with 50 µg ml-1 kanamycin. Inoculate each of these (main culture) with 12.5 ml of the pre-culture (i.e., prepare a 1:100 dilution) and grow to an OD600 of 0.6 (37°C, 140 rpm).

5.Supplement each flask with 12.5 ml of 1 M N-(ε)-acetyl-L-lysine (final concentration in culture: 10 mM) and 12.5 ml of 2 M nicotinamide (final concentration in culture: 20 mM). Reduce temperature to 18°-20°C.

6.After 30 min, add IPTG to a final concentration of 100 µM to induce the expression of the POI (here: His6-Ran AcK71) and incubate for 12-24 hr (at 18°-20°C, 140 rpm).

7.Harvest the cells by centrifugation (10,000 × g , 4°C, 20 min).

8.Resuspend the cell pellet in resuspension buffer (buffer 1.1) and store the pellet at −80°C. Use ∼10-15 ml of resuspension buffer per pellet from 1 L of culture.

Purification of Ran AcK71 (see Current Protocols article: Wingfield, 2015)

9.Thaw the cell pellet on ice. Transfer the suspension into a glass beaker and lyse cells by sonication on ice (five cycles of 2 min, intensity 60%, pulse 0.5 s/2.0 s).

10.Centrifuge the lysate at 39,000 × g , 4°C, for 45-60 min to remove the insoluble fraction. While waiting for the centrifugation, prepare the Ni2+-NTA metal affinity column (5-ml HisTrapTM FF crude column) by equilibrating it with 5 column volumes (CVs) of buffer 1.1.

11.Load the cleared supernatant (which contains the POI; here: His6-Ran AcK71) onto the Ni2+-NTA metal affinity column (5 ml HisTrapTM FF crude column) using an automated FPLC system (Cytiva, Bio-Rad) at 4°C.

12.Wash the column with >10 CVs washing buffer (buffer 1.2) to remove unspecifically bound proteins and contaminants. Wash with 2 CVs of buffer 1.3.

13.Elute the POI on an FPLC system, applying a 10-500 mM imidazole gradient using buffer 1.3 and buffer 1.4.Follow the absorption at 280 nm (A 280) to monitor elution of the POI and the conductivity to monitor the imidazole gradient over time. Collect the flow-through using automated FPLC system and fraction collector.

14.Analyze the protein-containing fractions by SDS-PAGE (see Current Protocols article: Gallagher, 2012).

15.Pool the fractions containing the POI and concentrate via ultrafiltration (4°C, 4000 × g) using an Amicon® Ultra centrifugal filter device with a suitable MWCO, following the manufacturer's instructions.

16.Equilibrate the SEC column with >2 CVs of SEC equilibration buffer (buffer 1.5).

17.Load the concentrated POI (from step 15) onto the equilibrated SEC column and elute on medium-pressure chromatography system using buffer 1.5.Monitor the elution by following the A 280. Collect the eluate using a fraction collector.

18.Analyze the protein-containing fractions by SDS-PAGE (Gallagher, 2012) to identify the POI-containing fractions (see Gallagher, 2012). Then, pool the POI-containing fractions, concentrate the POI using an Amicon Ultrafiltration device, and determine the concentration of the POI (by measuring A 280). Aliquot the POI-containing solution, snap freeze the solution in liquid nitrogen, and store the POI at −80°C until further use.

19.Evaluate the successful incorporation of acetyl-L-lysine by immunoblotting using a specific anti-acetyl-lysine antibody (Fig. 2C) (see Basic Protocol 2).

Basic Protocol 2: IN VITRO SIRTUIN (SIRT)-CATALYZED DEACETYLATION OF LYSINE-ACETYLATED PROTEINS PREPARED BY THE GCEC

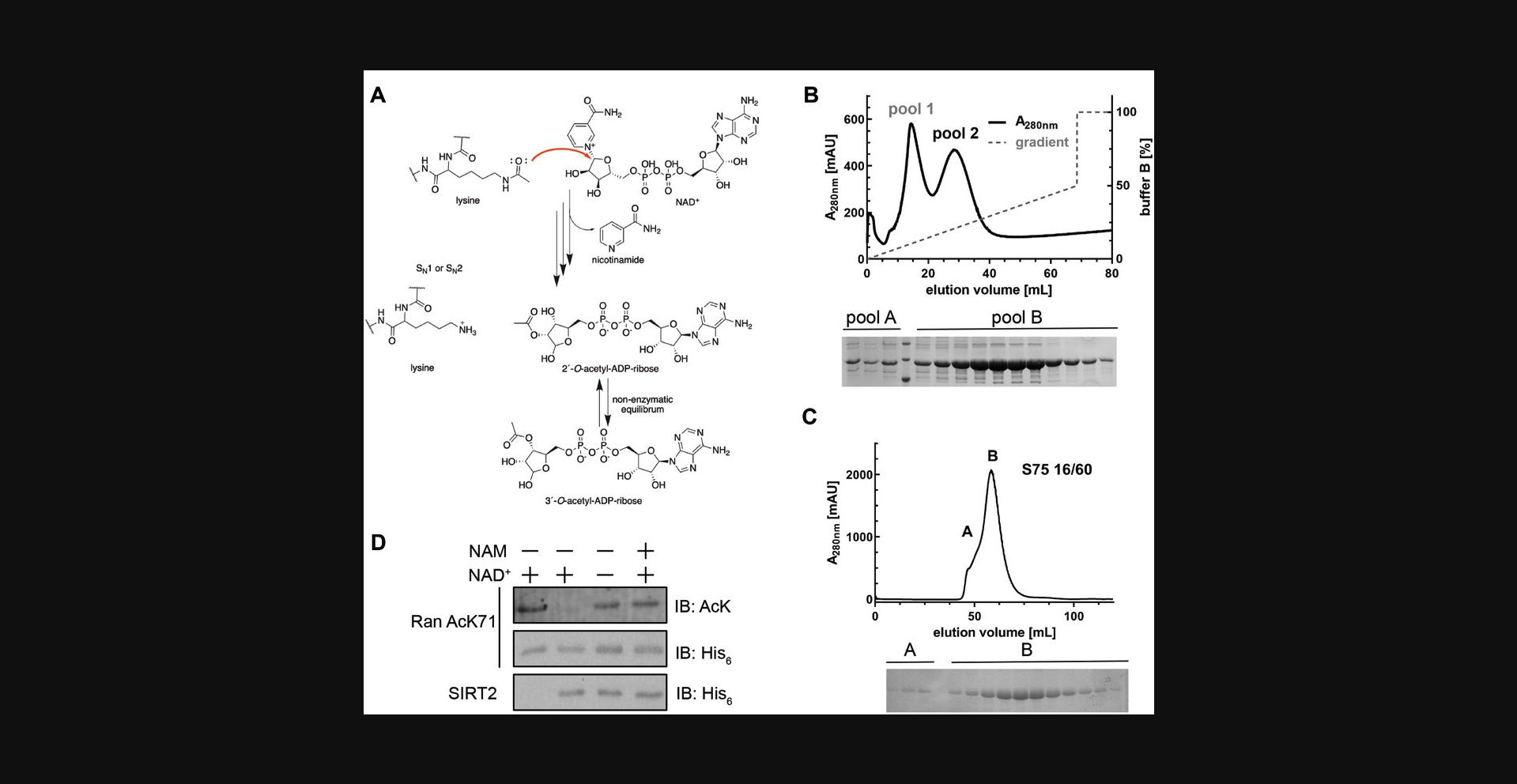

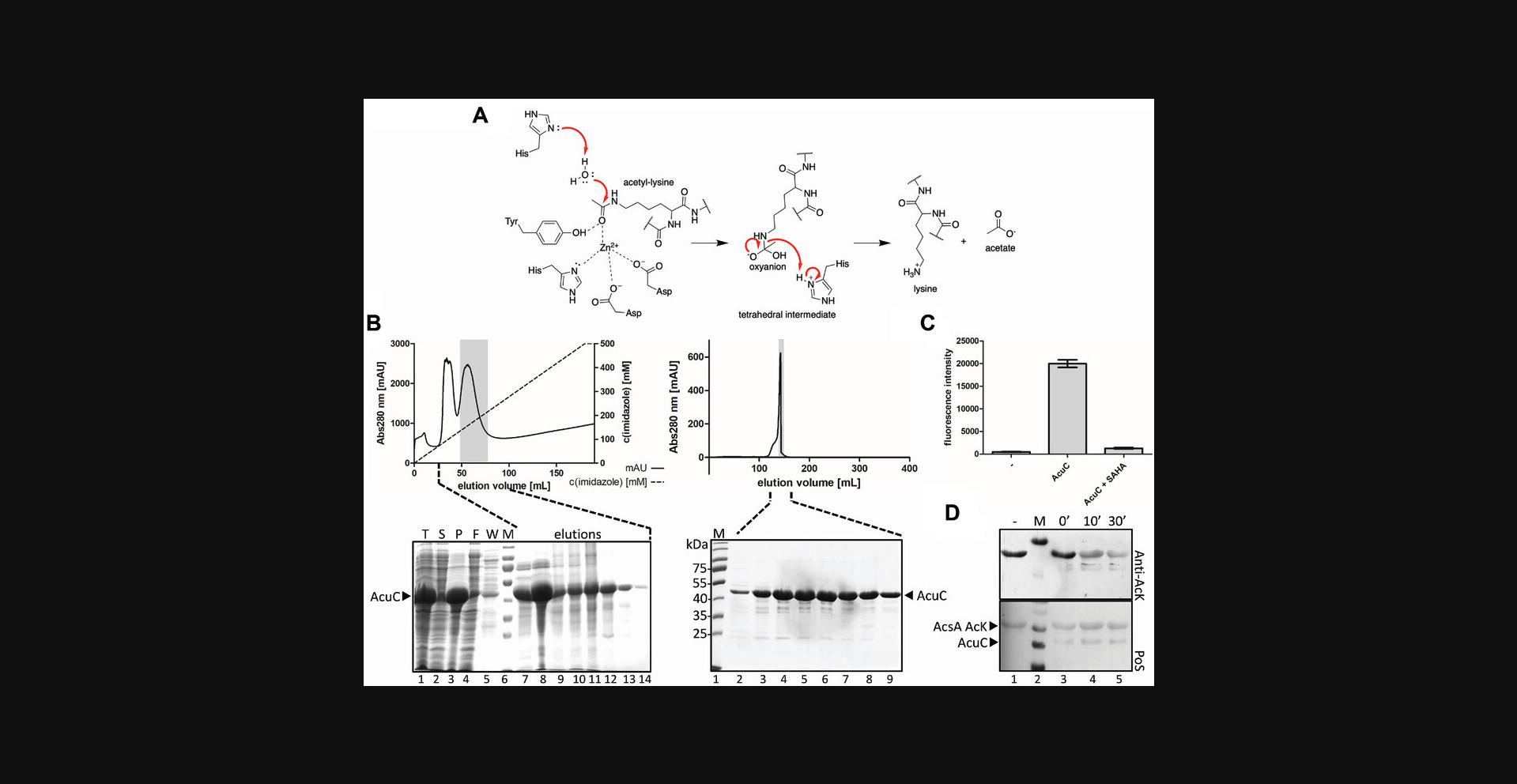

This protocol describes how natively folded and site-specifically lysine-acetylated proteins prepared by genetic code expansion (GCEC; Basic Protocol 1) can be used as substrates for sirtuin-catalyzed deacetylation assays. Sirtuin deacetylases (short: sirtuins; SIRT: silent information regulator) are NAD+-dependent enzymes, which are important regulators of fundamental cellular processes (Fig. 2A). Of the seven mammalian sirtuins known (SIRT1-7), SIRT 1-3 are well-documented to possess robust lysine deacetylase activity, while the others show more complex enzymatic activities. Here, we describe the expression and purification of SIRT2 (Fig. 4B and 4C), as well as a deacetylation assay using the site-specifically lysine-acetylated protein His6-Ran AcK71 (Basic Protocol 1) as a substrate (Fig. 4D). This assay is designed to directly identify deacetylases for individual acetylation sites in proteins. Following the initial expression of the gene encoding for the sirtuin of interest in E. coli (here: His6-SIRT250-356), a two-step purification strategy consisting of Ni2+-NTA affinity chromatography (Fig. 4B) and size-exclusion chromatography (SEC) (Fig. 4C) is used to obtain a protein sample of sufficient purity for the deacetylation assay, which uses immunoblotting with a specific anti-acetyl-lysine antibody as a readout (Fig. 4D).

Materials

-

Competent E. coli (BL21) DE3 cells (Novagen®; Sigma-Aldrich, cat. no: 69450)

-

Plasmid pRSF-Duet1 (Sigma-Aldrich, cat. no. 71341) encoding the sirtuin of interest (here, His6-SIRT250-356)

-

LB agar plates (see recipe) containing 50 µg L-1 kanamycin (Carl Roth, cat. no: T832.2)

-

Lysogeny broth (LB) medium (see recipe)

-

Kanamycin sulfate (50 mg ml-1 stock in H2O; Carl Roth, CAS no. 25389-94-0)

-

Isopropyl β-D-1-thiogalactopyranoside (IPTG), 1 M stock, in water (Carl Roth, CAS no. 367-93-1)

-

Buffers 2.1 (resuspension buffer), 2.2, 2.3, 2.4, 2.5 (assay buffer), 2.6 (stripping buffer) (see recipes)

-

5× SDS-PAGE sample buffer (see recipe)

-

my-Budget Pre-stained Protein Ladder (Bio-Budget, cat. no. 86-1000-0500)

-

4%-12% (v/v) SDS-PAGE gels

-

SDS-PAGE running buffer (see recipe)

-

SDS-PAGE staining solution (see recipe)

-

Liquid nitrogen (CAUTION : handle with care; use protective equipment for extremely low temperatures and provide a well-ventilated environment)

-

Acetylated POIAck (see Basic Protocol 1 for His6-Ran AcK71)

-

200 mM nicotinamide (Sigma-Aldrich, cat. no. N3376) in sterile filtered (0.22 µm filter) deionized water. Prepare fresh

-

5 mM NAD+ stock solution (β-nicotinamide adenine dinucleotide sodium salt; Sigma-Aldrich, cat. no.: N0632)

-

Ponceau S red (VWR, Lot No.: 0447C180) in 10% acetic acid

-

PBS-T buffer (see recipe)

-

5% skimmed milk powder in PBS-T (see recipe)

-

Immunoblot transfer buffer (see recipe)

-

Methanol (Carl Roth, CAS no. 67-56-1)

-

Anti-acetyl-L-lysine antibody (abcam 21623, anti-rabbit; dilute 1:1000 in 5% w/v skimmed milk/PBS-T)

-

Goat HRP-coupled anti-rabbit IgG (ab6271, dilute 1: 10,000 in 5% w/v skimmed milk/PBS-T)

-

ECL solution (ROTI®Lumin; Carl Roth GmbH & Co- KG, cat. no. P078.2)

-

Phosphate-buffered saline (PBS; see recipe)

-

Anti-His6-tag antibody (ab18184, 1:1000 in 5% w/v skimmed milk/PBS-T)

-

Rabbit HRP-coupled anti-mouse IgG (ab6728, 1: 10.000 in 5% w/v skimmed milk/PBS-T)

-

5-L baffled Erlenmeyer flasks (VWR, cat. no. 214-1137)

-

Incubator (e.g., Function Line B20; Heraeus Holding GmbH)

-

Shaking incubator (e.g., Infors HT Multitron Standard; Infors AG)

-

UV/Vis spectrophotometer (e.g., Varian Cary 50 UV-Vis spectrophotometer or NanoDrop ND 1000, VWR International GmbH)

-

Heat block at 30°C and 95°C (Mixing Block MB-102, Bioer Technology Co.)

-

Centrifuge (SORVALL RC 6, ThermoFisher GmbH)

-

Refrigerated microcentrifuge

-

Sonicator (Sonopulse HD 4100, BANDELIN Electronic GmbH & Co. KG, Berlin, Germany)

-

1.5-ml microtubes (SARSTEDT AG & Co. KG, REF 72.690.001)

-

Sterile bottle-top filters, 0.45-μm pore size

-

5-ml His-TrapTM High Performance column (Cytiva, cat. no. 17524801, with Ni Sepharose® High Performance)

-

Automated FPLC system and fraction collector (Cytiva, Bio-Rad)

-

Electrophoresis chamber and power supply (e.g., Bio-Rad Laboratories GmbH)

-

Amicon® Ultra centrifugal filter unit (10 kDa; Merck, cat. no. UFC901024)

-

NanoDrop microspectrophotometer (NanoDrop ND 1000, VWR International GmbH)

-

Preparative size-exclusion column: HiLoad® 16/600 Superdex®75 pg column (Cytiva, cat. no. 2898933)

-

Medium-pressure chromatography system (low MPA range) with UV detection (280 nm) (e.g., Äkta Purifier, GE Healthcare)

-

0.2-ml microtubes

-

Nitrocellulose/PVDF membrane (Carl Roth GmbH & Co. KG)

-

Semi-dry Blotter Trans-Blot® TurboTM Transfer System (e.g., Bio-Rad Laboratories GmbH)

-

Chemiluminescent detection system (e.g., Octoplus QUPLEX, Intas Science Imaging Instruments GmbH)

-

Additional reagents and equipment for SDS-PAGE (see Current Protocols article: Gallagher, 2012) and immunoblotting (Western blotting; Ni, Xu, & Gallagher, 2016)

Expression of His6-SIRT250-356

1.Transform competent E. coli BL21 (DE3) cells with pRSF-Duet1/his6-sirt250-356.

2.Plate cells on LB agar plates containing 50 µg L-1 kanamycin.

3.Incubate overnight at 37°C (16-18 hr).

4.Prepare eight 5-L baffled flasks, each containing 1 L of LB medium with 50 µg L-1 kanamycin.

5.Inoculate each flask with 12.5 ml (i.e., 1:100 dilution) of the overnight preculture.

6.Grow cells under constant shaking (160 rpm) at 37°C.

7.Measure the optical density OD600 every 30 min until it reaches 0.6.

8.Adjust the temperature to 18°-20°C (this takes approximately 30 min).

9.Induce expression of the POI (here: His6-SIRT250-356) by adding IPTG to a final concentration of 100-400 µM.

10.Allow POI expression by incubating the cells at 18-20°C at 160 rpm overnight (for 12-16 hr).

11.Harvest the cells by centrifugation (4500 × g , 20 min, 4°C).

12.Discard the supernatant.

13.Resuspend the cells in ∼20 ml of resuspension buffer (buffer 2.1) and freeze the suspension at −80°C or proceed with protein purification (step 14).

Purification of His6-SIRT250-356

14.If frozen, thaw the cell suspension from step 13 on ice.

15.Lyse cells by sonication (two cycles with 5 min, intensity 55%, pulse 0.5 s/1.5 s).

16.Centrifuge the lysate at 50,000 × g for 45 min.

17.Transfer the supernatant containing the POI into a fresh 1.5-ml tube and discard the pellet.

18.Filter the supernatant using a bottle-top filter with a 0.45-µm pore size to remove any remaining cell debris.

19.Equilibrate the Ni2+-NTA affinity column (5 ml His-TrapTM High Performance column) with ≥3 CVs of buffer 2.2.

20.Load the supernatant onto the equilibrated Ni2+-NTA column using an automated FPLC system (4°C, flow rate ≤2 ml min-1).

21.Wash the column with 10 CVs of buffer 2.3 (flow rate 1-2 ml min-1 dependent on the column used). Follow the absorption at 280 nm (A 280) and wash the column until A 280 reaches a stable minimum.

22.Wash the column with buffer 2.2 (>2 CVs) to exchange the high-salt buffer 2.3.

23.Elute the SIRT2 by applying a 10-500 mM imidazole gradient from 100% buffer 2.2 to 100% buffer 2.4 over 10 CVs (flow rate 1 ml min-1). Collect the eluate in fractions of 1 ml using an automated FPLC system and a fraction collector (Fig. 4B). Monitor A 280 and the conductivity to follow protein elution and the formation of the imidazole gradient, respectively.

24.Select possible His6-SIRT250-356-containing fractions based on A 280 and prepare SDS-PAGE samples of each fraction (10 μl sample + 2.5 μl 5× sample buffer). Microcentrifuge briefly at room temperature. Heat the mix for 5 min at 95°C. Microcentrifuge briefly at room temperature.

25.Load 10 μl of each mix and 5 μl of pre-stained ladder on a 4% v/v-12% v/v SDS-PAGE gel. Run the gel in SDS-PAGE running buffer at 180 V until the dye front reaches the bottom of the gel (approximately 50 min).

26.Pool the fractions containing the POI and concentrate using an Amicon® Ultra centrifugal filter device with suitable molecular weight cutoff (MWCO).

27.Measure the concentration based on the extinction coefficient (EC) of the POI by assessing A 280 using a NanoDrop microspectrophotometer and applying the Lambert-Beer law.

28.Equilibrate a suitable size-exclusion chromatography (SEC) column (depending on the molecular weight, oligomeric state, and total amount of POI) with ≥1.5 CVs of equilibration buffer 2.5.

29.Perform size-exclusion chromatography (SEC) with buffer 2.5 using a medium-pressure chromatography system (low MPA range) with UV detection (280 nm) and running specifications according to the selected column.

30.Select possible POI-containing fractions by monitoring the A 280 and subsequent analysis of the protein-containing fractions by SDS-PAGE (Fig. 4B).

31.Pool the POI-containing fractions (separated by oligomeric state if necessary).

32.Concentrate the POI-containing fractions using an Amicon® Ultra centrifugal filter device with a suitable molecular weight cutoff (MWCO).

33.Determine the concentration of the POI by measuring A 280 using a NanoDrop microspectrophotometer and applying the Lambert-Beer law using the POI's specific extinction coefficient.

34.Flash-freeze the concentrated POI in liquid nitrogen and store in suitable aliquots at −80°C.

Sirtuin deacetylation assay

35.Thaw one aliquot of the acetylated POIAck (see Basic Protocol 1 for His6-Ran AcK71) and one aliquot of the prepared SIRT (here: His6-SIRT250-356; step 34) on ice.

36.Microcentrifuge (5 min at 13,500 rpm, 4°C) both tubes to remove precipitated proteins and other precipitants.

37.Transfer the supernatants to separate, fresh, pre-cooled 1.5-ml tubes and store on ice.

38.Measure the concentration of the POIAck and SIRT by applying the Lambert-Beer law using each protein's specific extinction coefficient and A 280 determined using a NanoDrop microspectrophotometer.

39.Calculate the volume of protein needed for preparing a 20-μl solution containing 5 µM POIAck (volume needed in assay: V A) and 1 µM SIRT (volume needed in assay: V B).

40.Prepare four tubes, e.g., 0.2-ml tubes, and label them with 1 through 4.

41.Use the pipetting scheme described in Table 1 for conducting the SIRT deacetylase assay.

| Final concentration | Sample 1 -SIRT/+NAD+ | Sample 2 +SIRT/+NAD+ | Sample 3 +SIRT/-NAD+ | Sample 4 +SIRT/+NAD+/+NAM |

|---|---|---|---|---|

| 5 µM POIAck | VA | VA | VA | VA |

| 1 µM sirtuin | - | VB | VB | VB |

| 0.5 mM NAD+ (5 mM stock) | 2 µl | 2 µl | - | 2 µl |

| 10 mM nicotinamide (200 mM stock) | - | - | - | 1 µl |

| Assay buffer (buffer 2.5) to 20 µl | X µl | X µl | X µl | X µl |

- a

Add the SIRT as last component and immediately start the incubation.

- b

Sample 1 corresponds to the non-enzyme control, sample 2 contains the SIRT co-substrate NAD+, sample 3 lacks the co-substrate NAD+ and nicotinamide (NAM), and sample 4 contains NAD+ and NAM in addition to SIRT and POIAcK.

- c

Applying this pipetting scheme allows one to confirm an NAD+-dependent SIRT-catalyzed deacetylation of POIAcK. VA, VB: volume of acetylated substrate protein (POIAcK) or sirtuin deacetylase, respectively.

42.Incubate samples in a heat block, incubator, or PCR cycler at 30°C for 2 hr 30 min.

43.Add 10 μl of H2O and 12 μl of 5× SDS-PAGE sample buffer to each reaction. Microcentrifuge briefly at room temperature. Heat the samples for 5 min at 95°C. Microcentrifuge briefly at room temperature.

44.Store samples at −20°C until further use, or proceed to SDS-PAGE and immunoblotting (detection of deacetylation by immunoblotting, step 45).

Detection of deacetylation by immunoblotting

45.If frozen, thaw samples from step 44.Load 10 μl of each sample for analysis by SDS-PAGE (step 48) and 5 μl of pre-stained ladder on a 4% v/v-12% v/v SDS-PAGE gel. Run the SDS-PAGE gel in SDS-PAGE running buffer at 180 V until the dye front reaches the bottom of the gel (∼50 min); also see step 24.

46.Blot on a PVDF or nitrocellulose membrane by semi-dry transfer in immunoblot transfer buffer at 150 mA for 30 min (for additional details, see Niet al., 2016).

47.To analyze the efficiency of the transfer of the proteins from the SDS-PAGE gel to the membrane, stain the membrane for 5 min with Ponceau S followed by washing with distilled, deionized H2O (for details, see Ni et al., 2016).

48.Wash the membrane in PBS-T at least three times, each time for 5 min at room temperature, until Ponceau S red−stained protein bands are no longer visible.

49.Block the membrane with 5% (w/v) skimmed milk in PBS-T for 1 hr at room temperature.

50.Incubate the membrane with primary anti-acetyl-L-lysine antibody overnight at 4°C with mild agitation.

51.Wash the membrane at least three times with PBS-T buffer, each time for 5 min.

52.Incubate with secondary goat HRP-coupled anti-rabbit IgG for 1 hr at room temperature with mild agitation.

53.Wash the membrane at least three times with PBS-T buffer, each time for 5 min.

54.Detect lysine-acetylated proteins using an enhanced chemiluminescence substrate for HRP (ECL solution) (Fig. 4C) using a suitable documentation system.

55.Incubate two times for 10 min with fresh stripping buffer (buffer 2.6).

The following steps are designed as an additional loading control by detecting the His6-tag of the SIRT and the POIAck

56.Wash two times for 5 min with PBS-T buffer followed by two times for 5 min with PBS buffer.

57.Continue with step 49 of this protocol but use anti-His6 antibody (ab18184, diluted 1:1000 in 5% w/v skimmed milk/PBS-T) as the primary antibody and HRP-coupled anti mouse IgG (ab6728, 1: 10,000 in 5% w/v skimmed milk/PBST) as the secondary antibody.

Basic Protocol 3: IN VITRO KDAC/HDAC-CATALYZED DEACETYLATION ON LYSINE-ACETYLATED PROTEINS

In this protocol, we describe the use of acetylated proteins to assess deacetylation catalyzed by classical KDACs. The enzymatic activity of purified KDAC can be determined in vitro with acetylated proteins produced via the GCEC method (Basic Protocol 1), using immunoblotting (Basic Protocol 2) and mass spectrometry (Basic Protocol 5) as readouts. As classical deacetylases produce acetate as a result of deacetylation, enzyme-coupled assays can be used to determine the amount of released acetate (Fig. 5A). Alternatively, fluorescently labeled peptides can be used to determine the activity of classical KDACs (and of sirtuins). This Fluor-de-Lys® assay uses histone- or p53-derived peptides that carry an acetyl-L-lysine and a coumarin fluorophore at the C-terminus. Upon deacetylation of the lysine in these peptides, the peptide becomes cleavable by a trypsin protease, which then liberates and unquenches the fluorogenic coumarin group, which allows detection by measuring fluorescence intensity. As such, this end-point assay allows one to quantify deacetylase activity and to screen for potential KDAC inhibitors (Wegener, Wirsching, Riester, & Schwienhorst, 2003). In this protocol, we use the Bacillus subtilis classical deacetylase AcuC (acu : acetoin utilization) as an example to describe this deacetylation assay. We describe the steps for expression of the test deacetylase in E. coli BL21 (DE3) and its purification, and the procedures for activity determination of classical KDACs (Fig. 5B). For determination of AcuC activity, we describe two assays. We report how the Fluor-de-Lys assay can be used to determine the activity of classical KDACs (Fig. 5C). In addition, we describe the assessment of deacetylation of the AcuC substrate AcsA (acetyl-CoA synthetase) using immunoblotting with a specific anti-acetyl-lysine antibody (anti-AcK antibody) as a readout, as described in Basic Protocol 2 (Fig. 5D).

Materials

-

Competent E. coli BL21 (DE3) cells (Novagen®; Sigma-Aldrich, cat. no. 69450)

-

pET-45b(+) vector (Novagen, Darmstadt, Germany) with (a) the acuC (N-terminal His6-Tag, UniProtKB entry: P39067), (b) acsA (N-terminal His6-Tag, UniProtKB entry: P39062), and (c) acuA sequence (N-terminal His6-tag, UniProtKB entry: P39065)

-

We used codon-optimized, synthetic genes prepared by BioCat (https://www1.biocat.com/).

-

LB agar plates (see recipe) containing 100 µg ml-1 ampicillin

-

Ampicillin sodium salt (100 mg ml-1 stock in H2O; Sigma-Aldrich, CAS no. 69-52-3)

-

Lysogeny broth (LB) medium (sterilize by autoclaving; see recipe)

-

Terrific broth (TB; sterilize by autoclaving; see recipe)

-

200 mM ZnCl2 (Carl Roth, CAS no. 7646-85-7) in water

-

Isopropyl β-D-1-thiogalactopyranoside (IPTG) (1 M stock in H2O; Carl Roth, CAS no. 367-93-1)

-

Buffer 3.1 (KDAC lysis buffer), 3.2 (KDAC washing buffer), 3.3 (KDAC standard buffer), and 3.4 (KDAC elution buffer) (see recipes)

-

5× SDS-PAGE sample buffer (see recipe)

-

Ladder: my -Budget Pre-stained Protein Ladder (Bio-Budget, cat. no. 86-1000-0500)

-

12% v/v SDS-PAGE gel and SDS-PAGE running buffer (see recipe)

-

SDS-PAGE staining solution (see recipe)

-

SDS-PAGE destaining solution (see recipe)

-

Ponceau S red (VWR, Lot No.: 0447C180) in 10% acetic acid

-

Bradford assay (Carl Roth, cat. no.: K015.1)

-

Liquid nitrogen (CAUTION : handle with care; use protective equipment for extremely low temperatures and provide a well-ventilated environment)

-

Fluorogenic KDAC substrate (Boc-Lys(Ac)-AMC; BACHEM, cat. no. I-1875)

-

DMSO (Cayman Chemical, CAS no. 149647-78-9)

-

Trypsin (Sigma Aldrich, CAS no. 9002-07-7)

-

10 mM stock solution of SAHA (suberoylanilide hydroxamic acid) in DMSO (Cayman Chemical, CAS no. 149647-78-9)

-

10 mM stock of Trichostatin A (TSA) in DMSO (Hycultec, cat. no. HY-15144)

-

25% (v/v) HCl

-

2× Fluor-de-Lys developer solution (see recipe)

-

50 mM Tris⋅HCl, pH 8.0

-

50 mM KCl

-

Acetylated POIAck (see Basic Protocol 4 for His6-AcsA)

-

PBS-T (see recipe)

-

Immunoblotting transfer buffer (see recipe)

-

5% (w/v) skimmed milk powder in PBS-T (see recipe)

-

Antibodies (5% w/v skimmed milk/PBS-T):

- Primary antibody: 1:1000; anti-acetyl-L-lysine antibody (abcam, cat. no. ab21623)

- Secondary antibody: 1:10,000; goat Anti-Rabbit IgG H&L (HPR) (abcam, cat. no. ab6721)

-

ECL solution A and B (see recipes)

-

100-ml and 5-L baffled Erlenmeyer flasks (VWR cat. no. 214-1131 and 214-1137)

-

Incubator (e.g., Function Line B20, Heraeus Holding GmbH)

-

Shaking incubator (e.g., Infors HT Multitron Standard, Infors AG)

-

Heat block (e.g., Mixing Block MB-102, Bioer Technology Co. and Digital Heatblock, VWR International GmbH)

-

UV/Vis spectrophotometer (e.g., Varian Cary 50 UV-Vis spectrophotometer or NanoDrop ND 1000, VWR International GmbH)

-

Refrigerated microcentrifuge

-

Centrifuge (e.g., SORVALL RC 6 with Rotor SLA-1500 and Rotor SS-34, Thermo Fisher GmbH)

-

Sonicator [e.g., Sonopulse HD 4100 with UW 100, TS133V, SH 100G, and tip TT213 (ᴓ12.7 mm); BANDELIN Electronic GmbH & Co. KG, Berlin, Germany]

-

5-ml HisTrapTM High Performance column (Cytiva, cat. no. 17524801, packed with Ni Sepharose® High Performance)

-

Amicon® Ultracentrifugal filter unit (10 kDa MW cut off; Merck, cat. no. UFC901024)

-

Electrophoresis chamber and power Supply (e.g., Bio-Rad Laboratories GmbH)

-

Preparative size-exclusion chromatography column: HiLoad® 16/600 Superdex®75 pg column and HiLoad® 16/600 Superdex®200 pg (Cytiva, cat. no. 2898933 and 28989335) or Superose 6 Increase 10/300 GL (Cytiva, cat. no. 29091596)

-

Medium pressure chromatography system (low MPA range) with UV detection (280 nm) (e.g., Äkta Purifier, GE Healthcare) and a fraction collector

-

Black Corning 96-well plates with flat bottom

-

Sealing tape for 96-well plates (Greiner Bio-One International GmbH, cat. no. 676001)

-

Plate reader Infinite 200 PRO (Tecan), or similar

-

1.5-ml microtubes (SARSTEDT AG & Co. KG, REF 72.690.001)

-

0.45-µm syringe filter

-

Polyvinylidene fluoride (PVDF) membrane and filter paper (Bio-Rad, cat. no 1620263)

-

Semi-dry Blotter Trans-Blot® TurboTM Transfer System (e.g., Bio-Rad Laboratories GmbH)

-

Shaker/Nutator

-

Chemiluminescent detection system (e.g., Octoplus QUPLEX, Intas Science Imaging Instruments GmbH)

-

Additional reagents and equipment for SDS-PAGE (see Current Protocols article: Gallagher, 2012) and immunoblotting (Western blotting; Ni, Xu, & Gallagher, 2016)

Expression of acuC

1.Transform E. coli BL21 (DE3) cells with the expression plasmid [here: pET-45b(+)] encoding for B. subtilis AcuC. Plate the cells on a LB agar plates containing 100 µg ml-1 ampicillin.

2.Pick 4-5 single colonies to inoculate a 50-ml preculture in LB medium containing 100 µg ml-1 ampicillin. Grow overnight at 150-160 rpm, 37°C.

3.The next day, transfer 20 ml of the preculture to 2 L of TB (i.e., do a 1:100 dilution) in a 5-L Erlenmeyer flask and grow the culture to an optical density at 600 nm (OD600) of 0.3 (37°C, 140 rpm).

4.Lower the temperature to 18°C and add ZnCl2 to the medium to a final concentration of 200 µM.

5.Grow the cells for an additional 30 min and induce the expression of acuC overnight by adding 400 μl of a 1 M IPTG stock solution (final concentration: 200 µM of IPTG) to the flask containing the 2 L of culture.

6.The next day, harvest the cells by centrifugation (4000 × g , 10 min, 4°C).

7.Resuspend the cell pellet in 40 ml of KDAC lysis buffer (buffer 3.1).

8.Lyse the cells by sonication on ice (cycle 5 min, intensity 55%, pulse 0.5/1.5 s).

9.Centrifuge the lysate (45 min, 40,000 × g , 4°C) and use the supernatant for protein purification. Discard pellet.

Protein purification of AcuC from B. subtilis (AcuC)

Have a Zn2+-charged Zn2+-NTA column prepared, as described in Strategic Planning.

10.Load the supernatant containing all soluble components in KDAC lysis buffer (buffer 3.1) onto an equilibrated zinc-charged NTA column (Zn2+-NTA; HisTrapTM High Performance column).

11.Wash the column with 10 CVs of KDAC washing buffer (buffer 3.2).

12.Elute the protein by applying a 0-500 mM imidazole gradient from 100% KDAC standard buffer (buffer 3.3) to 100% KDAC elution buffer 3.4 over 5 CVs.

13.Analyze the elution fractions by SDS-PAGE (see Current Protocols article: Gallagher, 2016). Collect the fractions containing the POI and concentrate the solution using an Amicon® Ultra centrifugal filter device. Microcentrifuge (4000 × g , 5 min, 4˚C) the concentrated protein solution to remove precipitants. Determine the protein concentration by Bradford assay.

14.Equilibrate the size-exclusion chromatography (SEC) column (HiLoad® 26/600 Superdex®200 pg) with the KDAC standard buffer (buffer 3.3). Load the protein and elute it using the same buffer (buffer 3.3).

15.Analyze the elution fractions by SDS-PAGE (see Current Protocols article: Gallagher, 2012). Collect the POI-containing fractions and concentrate the target protein using an Amicon ultrafiltration device.

16.Flash-freeze the concentrated protein aliquots in liquid nitrogen and store them at –80°C.

Fluor-de-Lys assay

17.Prepare a 10 mM stock solution of the fluorogenic KDAC substrate in DMSO. Boc-Lys(Ac)-AMC is highly soluble in DMSO. Protect the fluorogenic substrate solution from prolonged exposure to light, and store at −20°C.

18.Prepare 2× Fluor-de-Lys developer solution as described in Reagents and Solutions.

19.Prepare two Fluor-de-Lys reaction mixes, one with and one without KDAC inhibitor (SAHA or TSA). Prepare a mixture containing:

- 50 mM Tris·HCl (pH 8.0)

- 50 mM KCl

- 5 µM KDAC (AcuC from step 16)

- 20 µM fluorogenic KDAC substrate

- 1% v/v DMSO.

- To one of the mixes, add 50 µM KDAC inhibitor (SAHA or TSA). To the other, add the corresponding volume of DMSO.

For the reactions with KDAC inhibitor, incubate the mixture with KDAC and inhibitor on ice for 15 min before adding the KDAC substrate to the mixture, and mix in the last step.

20.Add 100 μl of the Fluor-de-Lys reaction mixtures, containing 5 µM KDAC and the KDAC substrate (here: (Boc-Lys(Ac)-AMC), to wells of a black Corning® 96-well plate with flat bottom.

21.Cover the plate with sealing tape and incubate at room temperature or 37˚C in the dark for 30 min.

22.Quench the reaction and initiate the cleavage of the deacetylated substrate by trypsin protease by adding 100 μl of the Fluor-de-Lys developer solution from step 18.Incubate at room temperature in the dark for 30 min.

23.Using a 96-well microtiter plate reader, determine the fluorescence at 460 nm by exciting the fluorophore at the wavelength of 390 nm.

Deacetylation assay with acetylated protein

24.Prepare 200 μl of a reaction mixture in 1.5-ml tubes containing:

- 10 nM-5 µM KDAC (AcuC from step 16)

- 10 µM of acetylated protein (Basic Protocol 4)

- 1% v/v DMSO

- 50 mM KCl

- 50 mM Tris·HCl (pH 8).

- After adding the acetylated protein, incubate the mixture at room temperature or 37°C.

The KDAC concentration and substrate concentration to use are enzyme dependent. For a qualitative assay to compare different enzymes or different mutant versions of one enzyme, it is important to ensure which assay settings (enzyme/substrate concentration, incubation time, incubation temperature, buffer conditions, etc.) are selected which ensure that the reaction is still within the dynamic range, i.e., the substrate is not consumed. If that were to happen, it would not be possible to relatively compare the enzymes/mutants. For quantitative analyses, such as for Michaelis-Menten kinetics, the enzyme concentration should be less than 10-fold below the substrate concentration of the reaction, and the substrate must not be fully consumed during the reaction. Ideally, less than 10%-20% turnover of substrate should occur under the experimental settings used.

25.At defined time points (0, 5, 10, 20, 30, 45, 60, 90, and 120 min), take 20 μl of the sample and stop the reaction by adding 5 μl of 5× SDS-PAGE sample buffer supplemented with 2.5-50 µM SAHA.

26.Denature the samples at 95°C for 5 min and analyze by immunoblotting as described below (see Current Protocols article: Ni et al., 2016).

Immunoblotting

27.Run the denatured samples on an SDS-PAGE (Gallagher, 2012).

28.Transfer the proteins from the SDS-PAGE gel to a PVDF membrane in a blotting device using immunoblot transfer buffer (Ni et al., 2016). After transfer, rinse the membrane with PBS-T.

29.Incubate the membrane in Ponceau S red solution (0.25% Ponceau S, 10% acetic acid) for 5 min on a shaker, carefully rinse with distilled water five times, and document the result as loading control.

30.Incubate the membrane with blocking solution (PBS-T supplemented with 5% w/v skimmed milk powder) for half an hour on a shaker.

31.Incubate the membrane with an appropriate dilution of an anti-acetyl-lysine antibody (here: abcam, cat. no. ab21623, 1:1000 in blocking buffer) overnight at 4°C on a nutator.

32.Wash the membrane three times with PBS-T, each with shaking on a nutator for 5 min. Incubate the membrane with a secondary antibody solution (use an appropriate dilution of a horseradish peroxidase coupled secondary antibody in the blocking buffer; here: 1:10,000 of abcam, cat. no. ab6721) for 1 hr at room temperature on a nutator.

33.Wash the membrane three times with PBS-T, each time for 5 min.

34.Mix 1 ml of ECL solution A (ECL A) and 1 ml of ECL solution B (ECL B), and rinse the membrane with the development solution mix. Document the result using a blot imaging system.

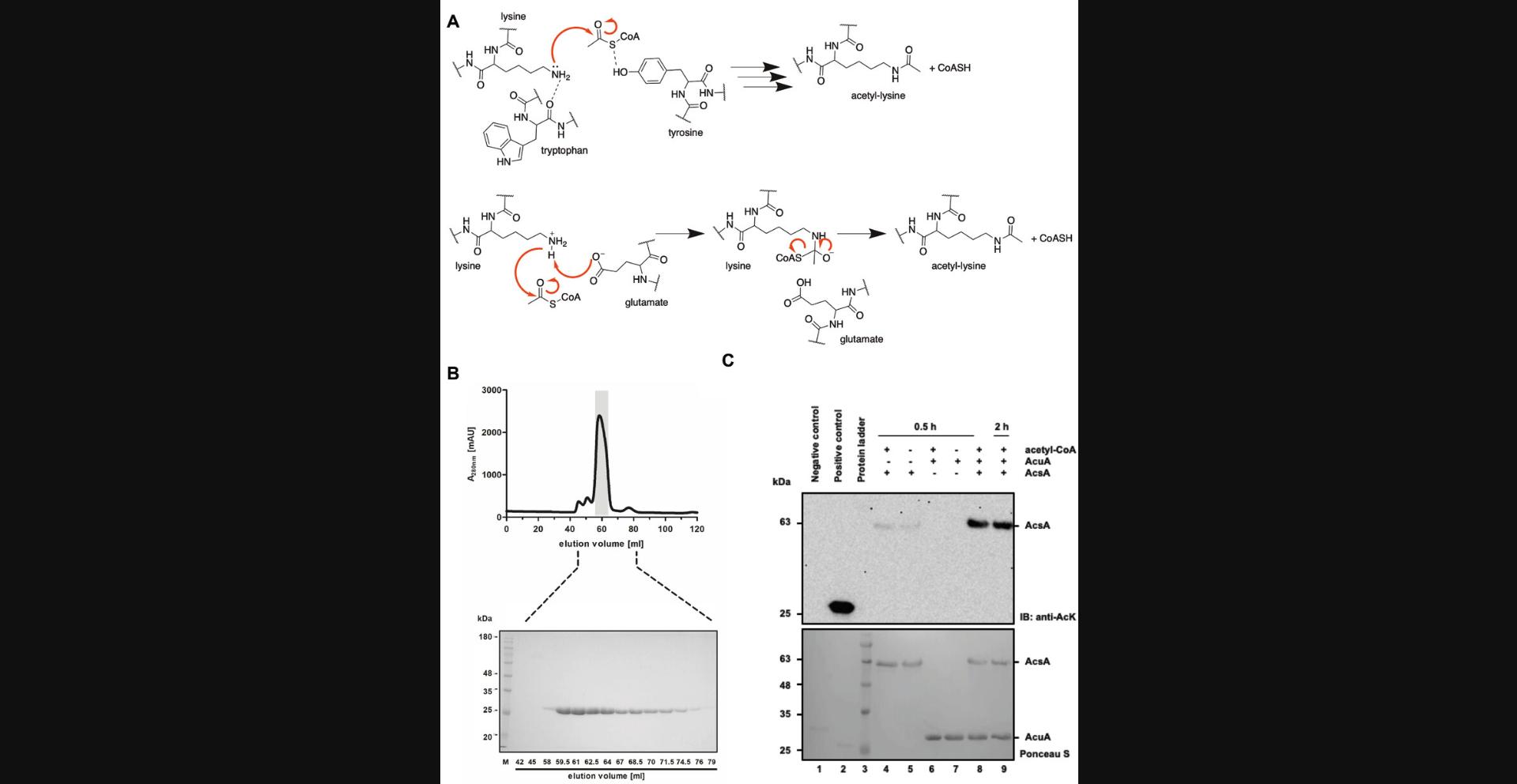

Basic Protocol 4: IN VITRO LYSINE ACETYLATION OF RECOMBINANTLY EXPRESSED PROTEINS BY LYSINE ACETYLTRANSFERASES (KATs)

In addition to the site-specific incorporation of acetyl-L-lysine into proteins by the genetic code expansion concept (GCEC; Basic Protocol 1), proteins can also be enzymatically acetylated at lysines. This protocol describes the steps to do this, using the enzymatic acetylation of K549 of acetyl-coenzyme A synthetase (AcsA) by a lysine acetyltransferase (AcuA) from Bacillus subtilis as an example (Fig. 6). Enzymatic lysine acetylation first requires the recombinant expression and purification of the substrate enzyme (in this case, AcsA) and the lysine acetyltransferase (in this example, AcuA; Fig. 6B). Expression is performed in Escherichia coli BL21 (DE3) cells, and purification takes place in two steps: firstly via an Ni-NTA affinity chromatography (IMAC: immobilized metal ion affinity chromatography) by the N-terminal His6-tag and, secondly, via a size-exclusion chromatography (SEC). The respective purification steps are monitored by recording the absorption at 280 nm (A 280) and additionally analyzed by SDS-PAGE. After purification, the proteins are concentrated using an Amicon® Ultra ultrafiltration device with a suitable molecular weight cutoff (MWCO) and flash-frozen in small aliquots (∼20 μl) in liquid nitrogen, which are stored at –80°C until use. Subsequently, the substrate protein (AcsA) can be lysine-acetylated by the test lysine acetyltransferase (AcuA) in the presence of acetyl-coenzyme A (acetyl-CoA). The acetylation is then detected by immunoblotting (Fig. 6C).

Materials

-

Competent E. coli BL21 (DE3) cells (Novagen®; Sigma-Aldrich, cat. no: 69450)

-

pET-45b(+) vector with the acsA sequence (N-terminal His6-Tag, UniProtKB entry: P39062) and pET-45b(+) vector with acuA sequence (N-terminal His6-Tag, UniProtKB entry: P39065) ordered as codon-optimized, synthetic DNA construct, from BioCat (https://www1.biocat.com/)

-

LB agar plates (see recipe) containing 100 µg ml-1 ampicillin

-

Ampicillin sodium salt (100 mg ml-1 stock in H2O; Sigma-Aldrich, CAS no. 69-52-3)

-

LB medium (sterilize by autoclaving; see recipe)

-

Terrific broth medium (TB; sterilize by autoclaving; see recipe)

-

Isopropyl β-D-1-thiogalactopyranoside (IPTG; 1 M stock in H2O; Carl Roth, CAS no. 367-93-1)

-

Resuspension buffer: Buffer 4.1 (see recipe) plus Pefabloc®SC Protease Inhibitor (Carl Roth, CAS no. 30827-99-7)

-

Buffer 4.1 (assay buffer), buffer 4.2 (Ni-II buffer), and buffer 4.3 (Ni-III buffer) (see recipe)

-

5× SDS-PAGE sample buffer (see recipe)

-

Ladder: my -Budget Prestained Protein Ladder (Bio-Budget, cat. no. 86-1000-0500)

-

12% v/v SDS-PAGE gel and SDS-PAGE running buffer (see recipe)

-

SDS-PAGE staining solution (see recipe)

-

SDS-PAGE destaining solution (see recipe)

-

Bradford assay (Carl Roth, cat. no.: K015.1)

-

Liquid nitrogen (CAUTION : handle with care; use protective equipment for extremely low temperatures and provide a well-ventilated environment)

-

Acetyl-coenzyme A sodium salt (e.g., Sigma Aldrich, CAS no. 102029-73-2)

-

Ponceau S red Solution (abcam, cat. no. ab270042)

-

Blocking buffer: 5% w/v skimmed milk powder in PBS-T (see recipe)

-

Antibodies (1: 10,000 in 5% w/v skimmed milk/PBS-T):

- Primary antibody: anti-acetyl-L-lysine antibody (abcam, cat. no. ab21623)

- Secondary antibody: goat Anti-Rabbit IgG H&L (HPR) (abcam, cat. no. ab6721)

-

PBS-T solution (see recipe)

-

Immunoblot transfer buffer (see recipe)

-

Phosphate-buffered saline (PBS; see recipe)

-

ECL solutions A and B (see recipes)

-

100-ml and 5-L baffled Erlenmeyer flasks (VWR, cat. no. 214-1131 and 214-1137)

-

Incubator (e.g., Function Line B20, Heraeus Holding GmbH)

-

Shaking incubator (e.g., Infors HT Multitron Standard, Infors AG)

-

Heat block (e.g., Mixing Block MB-102, Bioer Technology Co. and Digital Heatblock, VWR International GmbH)

-

UV/Vis spectrophotometer (e.g., Varian Cary 50 UV-Vis spectrophotometer or NanoDrop ND 1000, VWR International GmbH)

-

Refrigerated microcentrifuge

-

Centrifuge (e.g., SORVALL RC 6 with Rotor SLA-1500 and Rotor SS-34, Thermo Fisher GmbH)

-

100-ml glass beaker

-

Sonicator (e.g., Sonopulse HD 4100 with UW 100, TS133V, SH 100G, and tip TT213 (ᴓ12.7 mm) (BANDELIN Electronic GmbH & Co. KG, Berlin, Germany)

-

5-ml HisTrapTM High Performance column (Cytiva, cat. no. 17524801, packed with Ni Sepharose® High Performance) for AcuA

-

5-ml HiTrapTM TALON® crude column (Cytiva, cat. no. 28-9537-67)

-

Amicon® Ultra Centrifugal filter unit (10 kDa MW cut off; Merck, cat. no. UFC901024)

-

Preparative size-exclusion chromatography column: HiLoad® 16/600 Superdex®75 pg column and HiLoad® 16/600 Superdex®200 pg (Cytiva, cat. no. 2898933 and 28989335)

-

Medium pressure chromatography system (low MPA range) with UV detection (280 nm) (e.g., Äkta Purifier, GE Healthcare) and a fraction collector

-

1.5-ml microtubes (BRAND, cat. no. 780500)

-

Electrophoresis chamber and power supply (e.g., Bio-Rad Laboratories GmbH)

-

0.45 µm Polyvinylidene fluoride (PVDF) membrane and filter paper (Bio-Rad, cat. no 1620263)

-

Semi-dry Blotter Trans-Blot® TurboTM Transfer System (e.g., Bio-Rad Laboratories GmbH)

-

Chemiluminescent detection system (e.g., Octoplus QUPLEX, Intas Science Imaging Instruments GmbH)

-

Additional reagents and equipment for SDS-PAGE (see Current Protocols article: Gallagher, 2012) and immunoblotting (Western blotting; Ni, Xu, & Gallagher, 2016)

Expression of AcsA and AcuA

1.Transform two sets of E. coli BL21 (DE3) cells with the pET-45b(+) expression vectors containing the genes acsA and acuA , encoding for the enzymes AcsA or AcuA, respectively.

2.Plate cells after transformation on separate selective LB agar plates containing 100 µg ml-1 ampicillin and incubate the plates overnight at 37°C.

3.For each transformation, add 25 ml of LB medium containing 100 µg ml-1 ampicillin to a 100-ml baffled Erlenmeyer flask. Take 4-5 single colonies from each of the plates on step 2 and inoculate the corresponding pre-cultures. Incubate the pre-cultures overnight (37°C, 160 rpm).

4.Prepare two 5-L baffled Erlenmeyer flasks with 2 L TB medium supplemented with 100 µg ml-1 ampicillin. One will be for inducing expression of acsA and the other, for acuA. Inoculate the corresponding flasks with 20 ml of the appropriate pre-culture, E. coli BL21 (DE3)/pET45b(+)/acsA or E. coli BL21 (DE3)/pET45b(+)/acuA.

5.Incubate the cultures (37°C, 130 rpm) until the OD600 reaches 0.4.Induce protein expression by adding 400 μl of a 1 M IPTG stock (final IPTG concentration 200 µM). Lower the temperature to 18°C and continue the incubation with shaking for an additional 18 hr.

6.Harvest the cells by centrifugation (10,000 × g , 4°C, 20 min). Discard the supernatant and either immediately use the pellet and continue with cell lysis, or store the pellet at –20°C or –80°C until use.

Purification of AcsA and AcuA

The purification process of AcsA is almost identical to that of AcuA. Perform each step at 4°C.

7.Resuspend the cell pellet on ice in 40 ml of resuspension buffer (20 g wet cell pellet in 40 ml of resuspension buffer) and transfer the suspension into a 100-ml glass beaker. Disrupt the cells by sonication on ice (six cycles with 2 min, intensity 55%, pulse 0.5 s/1.5 s).

8.Centrifuge the cell lysate (39,000 × g , 4°C, 60 min) to remove insoluble cell debris.

9.Load the supernatant on a 5-ml metal affinity column equilibrated with assay buffer (buffer 4.1) (use for AcsA a HiTrap. TALON® crude metal affinity column and for AcuA a Ni Sepharose® High Performance metal affinity column) using a medium pressure chromatography system (low MPa range) with UV detection (280 nm) at 4°C. Wash the column with 15 column volumes (CVs) of buffer 4.2 to remove unbound proteins. Elute the target protein using an imidazole gradient from 20 mM imidazole (buffer 4.2) to 500 mM imidazole (buffer 4.3).

10.Pool the fractions containing the POI (here: AcsA and AcuA) based on monitoring the absorption at 280 nm (A 280) and the subsequent analysis of the protein containing fractions by SDS-PAGE; determine the concentration by Bradford assay and concentrate to 10-20 g/L protein by ultrafiltration at 4°C with a 10 kDa MW cut off Amicon® Ultra Centrifugal filter unit.

11.To obtain a high-purity POI sample, perform size-exclusion chromatography (SEC). Equilibrate the size-exclusion column (HiLoad® 26/600 Superdex®200 pg for AcsA; HiLoad® 26/600 Superdex®75 pg for AcuA) at 4°C with 1.5-2 CVs of assay buffer (buffer 4.1).

12.Load the concentrated target protein on the equilibrated size-exclusion column at 4°C and elute with 340 ml of assay buffer (buffer 4.1) using a medium pressure chromatography system (low MPa range). Set the flow rate to an appropriate flow rate to keep the pressure limit of the column (0.3 MPa) and collect the eluate in 3-ml fractions.

13.Pool the pure protein fractions representing a single oligomeric species from the SEC elution following analyses by SDS-PAGE (Gallagher, 2012; an example of SEC results and the subsequent identification of pure fractions by SDS-PAGE for AcuA is shown in Fig. 6B) and concentrate at 4°C to approximately 10 g L-1 using Amicon Ultra Centrifugal filter unit (10 kDa MW cut off). Afterwards, flash-freeze small aliquots (∼20 μl) in liquid nitrogen and store at −80°C until use.

In vitro lysine acetylation of AcsAK549 by lysine acetyltransferase AcuA

14.Prepare the following mix in a 1.5-ml microcentrifuge tube and mix gently by pipetting up and down:

- 34.4 μl of assay buffer (buffer 4.1)

- 1 μl of 10 mg ml−1 AcuA (final concentration 10 µM)

- 2.6 μl of 10 mg ml−1 AcsA (final concentration 10 µM)

- 2 μl of 1 mM acetyl-coenzyme A (final concentration 50 µM).

Acetyl-CoA is a thioester that is quite unstable in solution. Ideally, prepare a fresh solution right before starting the experiment. Add acetyl-CoA as final component to start the reaction.

15.Incubate at 37°C (e.g., Mixing Block MB-102) for 30 min.

16.After incubation, stop the reaction with 10 μl of 5× SDS-PAGE sample buffer and incubate the sample at 95°C in a heat block for 8 min.

17.To detect the acetylation signal, load 5 μl of the stopped sample in a 12% (v/v) SDS-PAGE gel (Gallagher, 2012). In addition, load a negative (a non-acetylated protein; here: Ran) and positive control (a lysine-acetylated protein; here: His6-Ran AcK71; see BP1) and a pre-stained protein ladder onto the gel. The controls are important to judge the immunoblotting procedure. After the electrophoresis, transfer the proteins from the SDS-PAGE gel onto a PVDF membrane.

18.As a loading control, and to assess the efficiency of protein transfer, stain the membrane with Ponceau S red solution for 5 min at room temperature and wash the membrane with Milli-Q water until signals are visible (Fig. 6C).

19.Block unspecific antibody binding sites on the membrane with 5% (w/v) skimmed milk powder (blocking buffer) for 2 hr at room temperature.

20.Incubate the membrane with the primary anti-acetyl-L-lysine antibody (here: abcam, cat. no. ab21623) for 2 hr at room temperature (prepare 10 ml at a dilution 1:5000 in blocking buffer).

21.Wash the membrane three times with PBS-T for 10 min and incubate with the secondary antibody (here: abcam, cat. no. ab6721) for 2 hr at room temperature (prepare 10 ml at a dilution of 1:5000 in blocking buffer)

22.Wash the membrane three times with PBS and incubate the membrane with 2 ml of ECL A and 2 ml of ECL B solution for 1 min at room temperature. Detect the ECL signal with a chemiluminescent imager (Fig. 6C).

Basic Protocol 5: IN VITRO NON-ENZYMATIC LYSINE ACETYLATION OF PROTEINS BY ACETYL-CoA AND/OR ACETYL-PHOSPHATE

This protocol describes the analysis of non-enzymatic, chemical acetylation of proteins and its detection using immunoblotting and LC-MS/MS. Determining the stoichiometry of a lysine acetylation event is important in order to judge its physiological significance. Under physiological conditions, N-(ε)-amino groups of lysines can be acetylated either enzymatically or non-enzymatically. As discussed above, non-enzymatic acetylation in the cell occurs at high concentrations of either acetyl-coenzyme A (acetyl-CoA; e.g., in the millimolar range in mitochondria of eukaryotic cells) or acetyl-phosphate (AcP; e.g., in the low millimolar range in Escherichia coli) and alkaline pH. This protocol describes the steps to perform non-enzymatic acetylation of N-(ε)-amino groups of lysine side chains of natively folded proteins. The concentration of acetyl-coenzyme A (20-1000 μM) or acetyl-phosphate (1-20 mM), the incubation temperature (25˚C-37˚C) and/or the incubation time (3-18 hr), and the accessibility of the N-(ε)-amino groups of lysine side chains of a protein determine the degree of lysine acetylation. The acetylation of a protein can be qualitatively detected by immunoblotting using an anti-acetyl-L-lysine antibody (anti-AcK antibody) in combination with a secondary antibody that allows detection of the signal (e.g., HRP-coupled or fluorescence-labeled compound). To unravel the specific site of lysine acetylation, liquid chromatography−tandem mass spectrometry (LC-MS/MS) is performed, as described below. We exemplify these protocols by describing non-enzymatic acetylation of a recombinantly expressed and purified protein by treatment with acetyl-CoA or acetyl-phosphate, and the subsequent identification of the acetylation sites applying LC–MS/MS.

Materials

-

Recombinantly expressed and purified protein of interest (for protein purification protocols, see Basic Protocols 2-4)

-

Bradford assay (Carl Roth, cat. no.: K015.1)

-

100 mM lithium potassium acetyl-phosphate (see recipe)

-

10 mM acetyl-coenzyme A trilithium (see recipe)

-

5× reaction buffer (see recipe)

-

5× SDS-PAGE sample buffer (see recipe)

-

Ladder: my -Budget Prestained Protein Ladder (Bio-Budget, cat. no. 86-1000-0500)

-

12% v/v SDS-PAGE gel and SDS-PAGE running buffer (see recipe)

-

SDS-PAGE staining solution (see recipe)

-

SDS-PAGE destaining solution (see recipe)

-

12% v/v mini-PROTEAN SDS-PAGE gel (Bio-Rad)

-

Pre-stained marker (Thermofisher scientific, cat. no. 26617)

-

Positive control (an lysine-acetylated protein; here: His6-Ran AcK71; see Basic Protocol 1)

-

Negative control (a non-acetylated protein; here: Ran; see Basic Protocol 1)

-

ECL solution A and B (see recipe)

-

Blocking buffers: 1%, 3%, and 5% (w/v) skimmed milk powder in PBS-T (see recipe)

-

Rabbit anti-acetyl-L-lysine antibody (abcam, cat. no. ab21623)

-

Goat anti-rabbit-HRP antibody (abcam, cat. no. ab6217)

-

Immunoblot transfer buffer (see recipe)

-

PBS-T solution (see recipe)

-

Methanol (Carl Roth, CAS no. 67-56-1)

-

50 mM triethylammonium bicarbonate (TEAB) buffer, pH 8.5 (Sigma Aldrich, cat. no. T7408)

-

RapiGestTM SF (Waters, cat. no. 186001861)

-

500 mM TCEP (tris-(2-carboxyethyl) phosphine hydrochloride) buffer (Sigma Aldrich, cat. no. C4706)

-

100 mM iodoacetamide (Sigma Aldrich, cat. no. I6125)

-

Endopeptidase trypsin solution (see recipe)

-

Trifluoroacetic acid (Sigma Aldrich, cat. no. 74564)

-

Wetting solution: 0.1% v/v acetic acid (3738.4, Carl Roth) in 70% v/v acetonitrile (7330.1, Carl Roth)

-

Equilibration solution (0.1% v/v acetic acid in 3% v/v acetonitrile)

-

Washing solution (0.1% v/v acetic acid in water)

-

Elution solution (0.1% v/v acetic acid in 60% v/v acetonitrile)

-

Buffer B (0.1% v/v acetic acid in acetonitrile)

-

ReproSil-Pur 120 C18-AQ (R13.aq.0003, Dr. Maisch GmbH, Ammerbuch-Entringen, Germany)

-

Tabletop microcentrifuge (Micro Star 17R, VWR, or equivalent)

-

1.5-ml microtubes (BRAND, cat. no. 780500)

-

NanoDrop spectrophotometer (DS-11 Series Spectrophotometer, DeNovix, or equivalent) or UV-Vis spectrophotometer (Cary 60 UV-Vis spectrophotometer, or equivalent)

-

Heating block (PCR machine) or water bath

-

SDS-PAGE system (Mini-PROTEAN Tetra handcast system, Bio-Rad, or equivalent)

-

Semi-dry blotting system (Trans-blot turbo transfer system Bio-Rad, or equivalent)

-

Immobilon-P membrane, PVDF, 0.45 μm (MERCK, Millipore cat. no. IVPH00010)

-

Shaker/Nutator

-

Gel documentation system (Octoplus OPLEX, NHDyeAGNOSTICS, INTAS Science Imaging, or equivalent)

-

Pierce C18 Tips (Thermo Fisher Scientific, cat. no. 87782)

-

Concentrator plus vacuum centrifuge (Eppendorf, cat. no. 5305000703)

-

Micro-flow UPLC system (EASY nLC, Thermo Fisher Scientific, or equivalent)

-

20-cm length, 100-µm inner diameter column

-

Mass spectrometer (Q Exactive Plus Orbitrap, Thermo Fisher Scientific, or equivalent)

-

MaxQuant, Version 1.6.17.0 (https://maxquant.org/)

-

Additional reagents and equipment for SDS-PAGE (see Current Protocols article: Gallagher, 2012) and immunoblotting (Western blotting; Ni, Xu, & Gallagher, 2016)

Non-enzymatic acetylation of proteins using Ac-CoA or AcP

Here, we describe the protocol for any protein. Start with one aliquot of purified protein (50-100 μl, 1-10 g/L).

1.Microcentrifuge the purified protein solution in a 1.5-ml microcentrifuge tube (10 min, 11,000 rpm, 4˚C).

2.Pipette the supernatant into a fresh 1.5-ml microcentrifuge tube. Avoid transferring any protein precipitation or protein pellet into the tube.

3.Determine the concentration of the pure protein solution by measuring the absorption at 280 nm (A 280) or by performing a Bradford assay [measuring the absorption of the reaction product at 595 nm (A 595)] or a similar procedure (e.g., BCA or amido black protein assay) to determine protein concentration with a UV-Vis spectrophotometer.

4.Dilute the protein sample with a suitable buffer to a concentration of 20-200 μM.

5.Set up one of the reactions shown in Table 2 or 3 for the non-enzymatic acetylation. Use either acetyl-phosphate or acetyl-coenzyme A. The tables describe a setup for testing acetylation at three different incubation temperatures (25, 30, and 37°C) and four concentrations of acetyl-phosphate or acetyl-CoA (0, 1, 5, and 20 mM) resulting in 12 conditions.

X(μl)=cproteininassaycproteinstock×totalvolume(μl)=10μM200μM×20μl=1.0μl

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample | Incubation temperature 25°C | Incubation temperature 30°C | Incubation temperature 37°C | |||||||||

| Volume of acetyl-phosphate [µl] | 0 | 2 (10 mM stock) | 10 (10 mM stock) | 4 (100 mM stock) | 0 | 2 (10 mM stock) | 10 (10 mM stock) | 4 (100 mM stock) | 0 | 2 (10 mM stock) | 10 (10 mM stock) | 4 (100 mM stock) |

| Protein concentration [µM] | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Reaction buffer (5×) [µl] | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Filtered ddH2O [µl] | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Total assay volume [µl] | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

6.Incubate the reactions in a heat block, e.g., PCR machine or water bath (25˚C, 30˚C/37˚C, 3-18 hr; also see Tables 2 and 3, 4).

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample | Incubation temperature 25°C | Incubation temperature 30°C | Incubation temperature 37°C | |||||||||

| Volume of acetyl-coenzyme A [µl] | 0 | 5 (100 μM stock) | 5 (1 mM stock) | 2 (10 mM stock) | 0 | 5 (100 μM stock) | 5 (1 mM stock) | 2 (10 mM stock) | 0 | 5 (100 μM stock) | 5 (1 mM stock) | 2 (10 mM stock) |

| Protein concentration [µM] | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Reaction buffer (5×) [µl] | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Filtered ddH2O [µl] | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Total assay volume [µl[ | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Problem | Possible Cause | Solution |

|---|---|---|

| Basic Protocol Basic Protocol 1 | ||

| High amounts of translational termination product | Translational stop at amber stop codon by RF1 | Check whether AcK was added and probably increase concentration; use E. coli ΔRF1 for expression. |

| ESI-MS does not show correct molecular weight of POI and/or immunoblotting for acetyl lysine does not show any signal |

CobB might have deacetylated POI during expression. Anti-acetyl-lysine antibody does not recognize the site |

Check whether nicotinamide was added to the culture and/or increase the concentration; use E. coli ΔCobB for expression Check dilution of the antibody used and amount of protein loaded on the SDS-PAGE gel, and increase accordingly. Prepare a fresh antibody dilution. Check transfer of proteins from the SDS- PAGE to the membrane. |

| High amounts of translational termination product but also of full-length protein | Low acetyl-L-lysine incorporation efficiency | Use C-terminal affinity tag to remove translational termination product; add additional copies of AckRS3 and/or MbPylTCUA encoding genes on compatible vector. |

| Basic Protocol Basic Protocol 2 | ||

| No acetylation signal | POIAck is not acetylated or antibody does not detect POIAck | Analyze POIAck by ESI-MS for acetyl-L-lysine incorporation and evaluate using antibody at different concentrations. |

| No deacetylation | POIAck is no substrate | Repeat the assay with different SIRT. |

| Sirtuin is not active | Test activity with known SIRT substrate. | |

| Slow substrate turnover | Extend assay incubation time or use a higher SIRT concentration. | |

| Weak deacetylation | Access of SIRT to acetylation site is limited, substrate is not a physiological substrate, or other factors are missing to enhance SIRT-catalyzed deacetylation | Extend incubation time or use different SIRT constructs. |

| Deacetylation with NAM | NAM concentration is too low | Repeat with new solution. |

| NAM was added following addition of the SIRT | Always add the SIRT last, particularly if the substrate is efficiently deacetylated by the SIRT. | |

| Basic Protocol Basic Protocol 3 | ||

| Strong aggregation of KDAC | Protein is denatured/partially unfolded in the KDAC elution buffer |

Reduce the time for Zn2+-NTA affinity chromatography and SEC. Include an initial purification step via Superose 6 SEC following Zn2+-NTA chromatography. |

| Protein is insoluble following expression | Optimize expression conditions (expression medium, expression time, modify IPTG concentration, expression host, etc.). | |

| Green/blue protein solution | KDAC binds Ni2+ ions and of Zn2+ ions | Strip the Ni2+-NTA resin with EDTA-containing stripping buffer and charge it with ZnCl2. |

| No deacetylation activity in FdL assay | Acidification affects the fluorescence and enzyme activity | Check pH value of assay. If necessary, increase the concentration of buffer agent. |

| Deactivation of KDAC in the Zn2+-ion-rich environment | Avoid adding additional Zn2+ to the assay buffer. | |

| No cleavage by trypsin | Trypsin is inactive | Prepare fresh developer solution, increase trypsin concentration. |

| No acetylation signal in immunoblotting | H2O2 is consumed in ECL solution B | Prepare fresh ECL solution B. |

| Anti-acetyl-lysine antibody does not recognize the acetylation site on the substrate | Use alternative approaches (mass spectrometry, acetate detection by coupled-enzymatic assay, etc.) to detect the deacetylation of the substrate. | |

| Basic Protocol Basic Protocol 4 | ||