Estimate phospholipids from microalgae

Ying-Yu Hu, Zoe V. Finkel

Abstract

Here we describe a protocol to estimate phospholipids from microalgae.

After extracting and measuring the total lipids from microalgae, the remaining lipid extract is dried using a nitrogen flow, followed by drying with magnesium sulfate at 90°C. However, it has been observed that traditional dry combustion at 500°C only decomposes approximately 50% of phospholipids (Hu et al., 2022). To achieve complete conversion of phospholipids to pyrophosphate, a temperature of around 800°C is required, but such high temperatures cannot be used with glassware. As the acid digestion method involves using only 500 µL of 0.2 M HCl, which must be placed in tightly capped glass vials to prevent concentration changes due to evaporation, combustion must be carried out using glassware instead of crucibles. It should be noted that the recovery rate of phospholipids is around 80% when combusted at 650°C, but this recovery rate is consistent, making the use of glass vials applicable. Therefore, we recommend using 650°C to combust phospholipids and using 80% to correct the final results.

The resulting ash is digested using 0.5 mL of 0.2 M HCl for 30 minutes at 90°C. After digestion, the resulting orthophosphate is detected by mixing the sample with a combination of molybdate and ascorbic acid to produce molybdenum blue, as described in Chen's work (1956).

Steps

Prepare phospholipids sample

Dry remaining organic phase extract of total lipids at 37°C under a stream of N2 gas (<2 psi)

Phosphate primary standard

KH2PO4 primary standard stock solution (≈ 1 mM)

Transfer about 1 g KH2PO4 into a beaker, cover the beaker with foil

Place the beaker into an oven, dry KH2PO4 at 110°C for at least 2h 0m 0s

Move KH2PO4 into a vacuum desiccator, allow KH2PO4 to cool to room temperature

Dissolve around0.136g dried KH2PO4 in 1LMilliQ water.* Use 1 L volumetric flask

- Take notes of the actual weight of KH2PO4 for final concentration of standard stock solution

Transfer standard stock solution into a 1 L bottle and store in the fridge.

High temperature dry combustion

Use diamond pen to engrave the sample vials with numbers. Log number and sample code.

0.17M MgSO4reagent:Dissolve 1.023g MgSO4 in 50 mL MilliQ water

Add 200µL 0.17M MgSO4 to the dry extract.

Cover the uncapped vials with foil and place in the oven at 90°C until samples are completely dry.

Equipment

| Value | Label |

|---|---|

| Forced air oven | NAME |

| VWR | BRAND |

| 89511-410 | SKU |

Combust dried samples at 650°C for 9h 0m 0s

Equipment

| Value | Label |

|---|---|

| Muffle furnace | NAME |

| F30428C | TYPE |

| Thermo | BRAND |

| 10-505-13 | SKU |

| https://www.fishersci.com/us/en/home.html | LINK |

Allow samples to gradually cool down in the muffle furnace.

Digestion

0.2M HCl reagent:

In a reagent bottle, dissolve one part of 12N HCl in 59 parts of MilliQ water

Preheat oven to 90°C

Add 0.5mL 0.2M HCl to each vial.

Tightly cap the vial and vortex.

Place vials in the oven for 0h 30m 0s

Cool samples down to Room temperature

Preparing standard working solutions

Preheat shaker/incubator to 37°C

Equipment

| Value | Label |

|---|---|

| SHAKING INCUBATOR | NAME |

| 71L | TYPE |

| Corning® LSE™ | BRAND |

| 6753 | SKU |

Standard working solutions and reagents can be prepared during sample digestion.

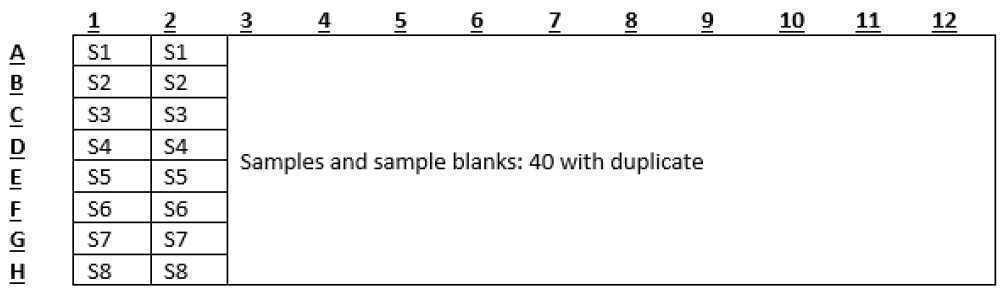

Standard working solution

| A | B | C |

|---|---|---|

| S1 | 0 | 1000 |

| S2 | 5 | 995 |

| S3 | 10 | 990 |

| S4 | 20 | 980 |

| S5 | 50 | 950 |

| S6 | 100 | 900 |

| S7 | 150 | 850 |

| S8 | 200 | 800 |

Transfer 500µL of each standard working solution to 2 mL microtube.

Preparing working reagents

All reagents are freshly prepared before colorimetric measurement.

2.5% ammonium molybdate reagent:

Weigh 0.25g ammonium molybdate in a Falcon tube and top to 10g with MilliQ water.

Cap and shake until totally dissolved.

10% ascorbic acid reagent (avoid light exposure):Weigh 1g ascorbic acid in a Falcon tube and top to 10g with MilliQ water;Cap and shake until all dissolved.

6N (3 M) sulfuric acid reagent:Carefully add 1 part 18M concentrated sulfuric acid into 5 part MilliQ water

Calculate the volume of molybdate-ascorbic reagent:

Total volume of reagent_mL = (0.5 mL) X (#standard working solution + #samples + #blanks)

Mix the reagents into Falcon tube:

| A | B |

|---|---|

| MilliQ | 2 |

| 6N sulphuric acid | 1 |

| 2.5% ammonium molybdate | 1 |

| 10% ascorbic acid | 1 |

Colorimetric measurement

Add 500µL reagent to each standard, sample (in the vial) and blank, starting from blanks, including blank for standards and blank for samples.

Equipment

| Value | Label |

|---|---|

| Finntip Stepper Tips | NAME |

| 5 mL | TYPE |

| Thermo Scientific | BRAND |

| 9404200 | SKU |

| https://www.fishersci.com/us/en/home.html | LINK |

Vortex.

Incubate at 37°C for 3h 0m 0s while shaking at 150 rpm

Read plate in microplate reader

| A | B |

|---|---|

| Shake duration | 00:00:05 |

| Shaking type | Continuous |

| Shaking force | High |

| Shaking speed [rpm] | 600 |

| Wavelength [nm] | 820 |

| Use transmittance | No |

| Pathlength correction | No |

| Measurement Time [ms] | 100 |

Equipment

| Value | Label |

|---|---|

| Varioskan LUX Multimode Microplate Reader | NAME |

| Thermo Fisher | BRAND |

| VL0L00D0 | SKU |

Calculation

Subtract the average absorbance at 820 nm of the blank standard replicates from the absorbance at 820 nm of all other standard working solutions.

Subtract the average absorbance at 820 nm of the blank sample (i.e. blank filter) replicates from the absorbance at 820 nm of all other individual samples.

Prepare a standard curve by plotting the average blank-corrected 820 nm absorbance for each standard working solution versus its concentration in uM.

Molar Mass of KH2PO4: 136.086 g/mol

Use the standard curve to determine the orthophosphate concentration of each unknown sample by using its blank-corrected 820 nm absorbance.

(Pmeasured)_umol/sample = (orthophosphate)_uM X (V_HCl)_mL X (0.001)

(Pcorrected)_umol/sample = (Pmeasured) / 0.8

Where, 0.8 is the average recovery of phospholipids after a high temperature dry combustion at 650°C .

(Phospholipids)_ug/sample = (Pcorrected)X30.97/(0.01X4.3)