Custom open-chamber microfluidic fabrication

Richard Wade-Martins, Quyen Do, Jimena Baleriola, Nora Bengoa-Vergniory

Abstract

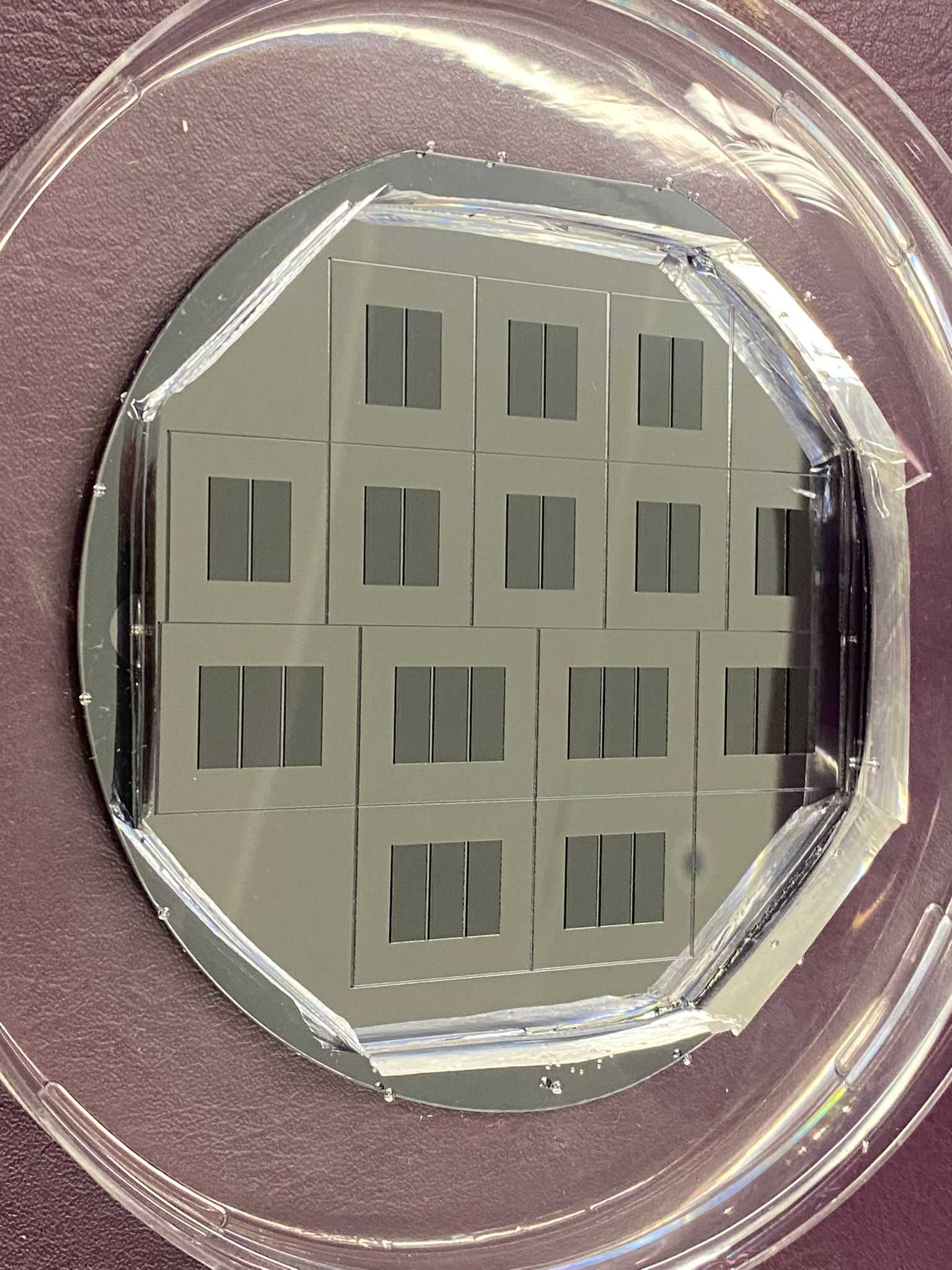

This protocol described the fabrication of two- and three-open chambered microfluidics suitable for cell culturing using commercially acquired master mould.

Before start

Always store cut-out devices in ethanol.

Avoid exposing microfluidic devices, particularly the cell-adherent side, to open air and unnecessary contact. Once sterilised, devices should be handled with care following sterile working techniques.

Steps

Casting of microfluidic devices

Mix 46 ml of silicon elastomer SylGARD 184, Dow Corning © with 4 mL of its curing agent (supplied in the same pack), i.e. the 1:10 ratio in a 50 ml falcon.

Mix well by inverting the falcon multiple times till a homogenous solution is seen by eye.

Slowly pour the mixture into the master mould and incubate for 2-2.5 hours at 60ºC.

Device preparation

Manually remove the final cast from the mould using a sharp blade.

Manually cut out individual devices and immediately wash them with 100% ethanol.

Air-dry cut-out devices in tissue culture hood.

Place dry and sterile devices on ethanol – sterilised 19 mm-diameter coverslips to form an instantaneously tight seal.

Coat both chambers and microchannel area with Poly-D-Lysin (0.1 mg/ml) overnight followed by Geltrex™ prior to cell culturing.