Production of Rhizoctonia solani inoculum for sugar beet disease trials

Travis Vagher, nicholas.metz, bradley.sowder, Amy Nielson, kevin.dorn

Abstract

Rhizoctonia solani is an economically important plant pathogen resulting in substantial losses of crop production within the United States and worldwide. In order to properly study resistance to this pathogen, having a consistent, uniform disease pressure of correct intensity is essential to effectively screen plant cultivars for relevant disease traits. This procedure details the process of producing inoculum in order to create a uniform Rhizoctonia solani disease trials.

Attachments

Colonized barley kernels.jpg colonized barley.jpg Contaminated barley.jpg contaminated flask.jpg contaminated plates.jpg Dried barley inoculum.jpg flask and lid.jpg flask with PDB.jpg flask with Rhizoc growing in PDB.jpg Flasks with Rhizoc growing in PDB.jpg ground inoculum.jpg Impulse polybag sealer.jpg Partly colonized barley.jpg plate colonized with Rhizoc..jpg plate colonized with Rhizoc.jpg plates for long term storage.jpg spawn bag.jpg wiley mill.jpg rhizoctonia solani inoculum production.docx

Steps

Preparation of culture for long term storage

Obtain desired isolate from either fungal isolation techniques or material transfer from a third party resource.

For sugar beet, the Rhizoctonia solani strain R9 (AG2-2IIIB) has been used for identifying lines of sugar beet with strong resistance.

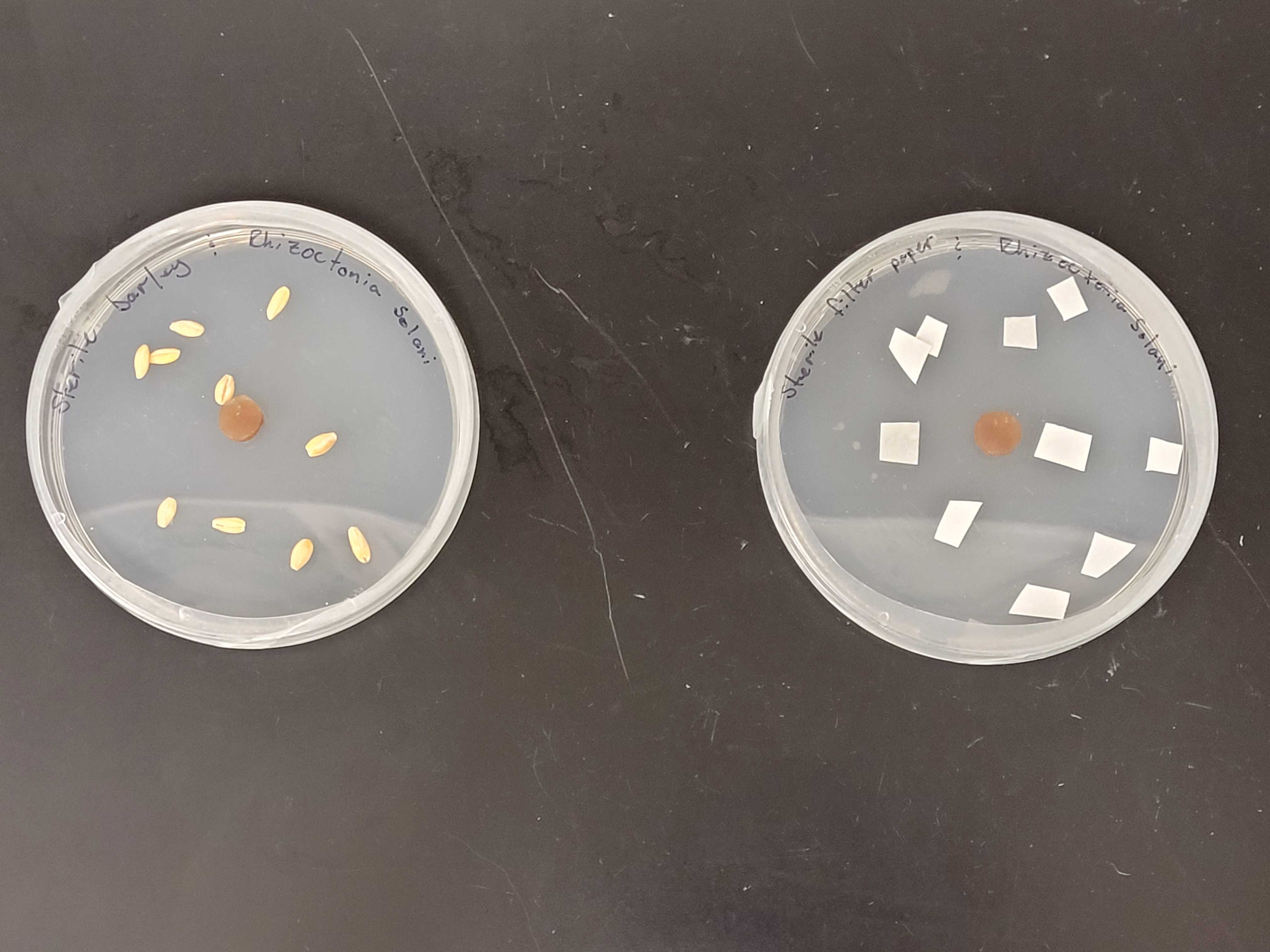

Prepare petri plates containing 25ml of potato dextrose agar and place sterilized medium to be colonized for long term storage atop of petri plate.

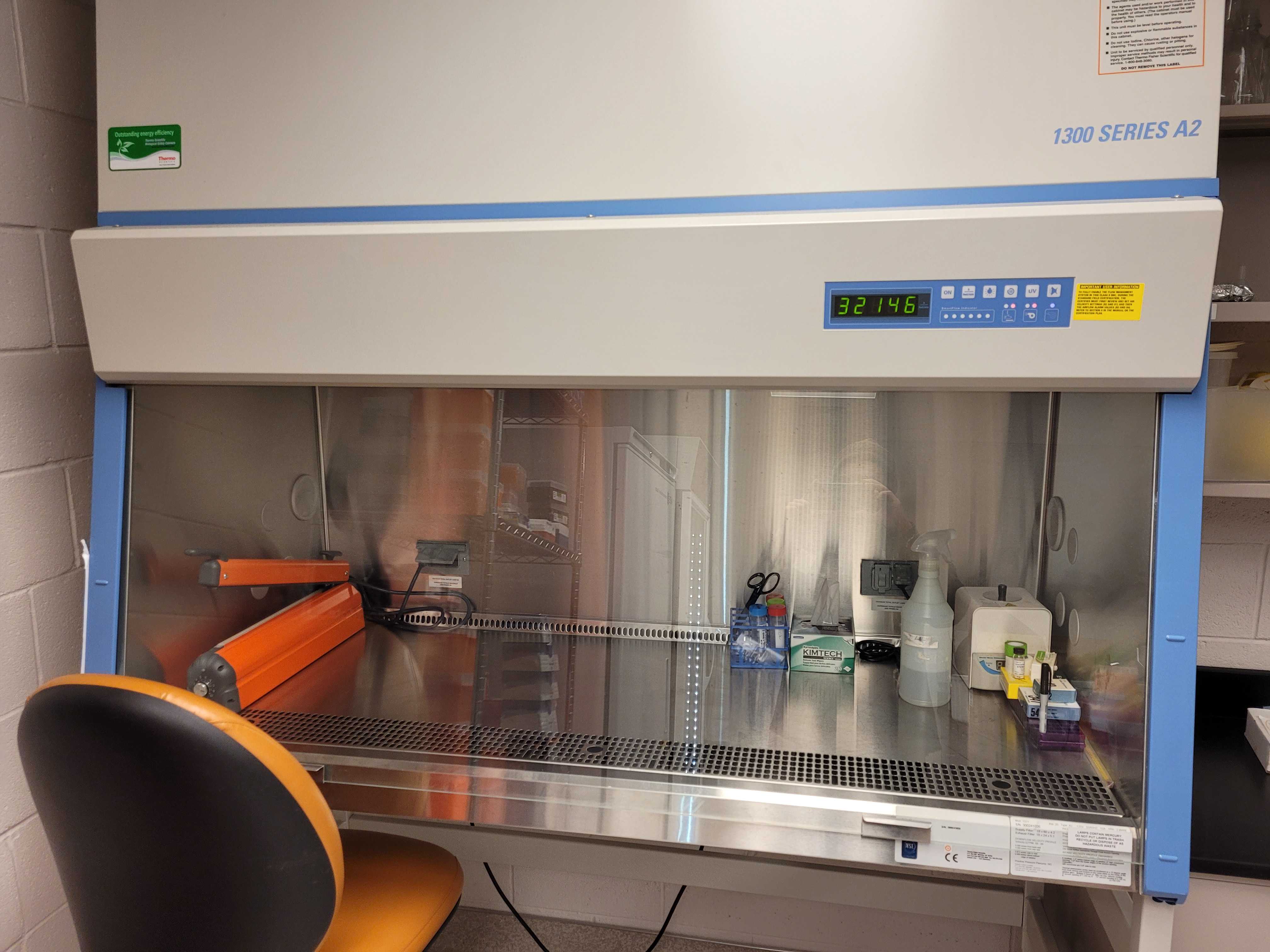

Suspend 39g of Difco™ Potato Dextrose Agar in 1L of purified water. Mix and heat with frequent agitation until the powder is completely dissolved. Autoclave at 121°C for 15 minutes. Let cool and aseptically, in a biological safety cabinet, pipette out 25ml for each sterile petri plate. Let solidify and return to sleeve for future use.

a. Sterile concentration disks or sterile barley kernels used as medium to be colonized for long term storage.

Using aseptic technique, in a biological safety cabinet, transfer desired fungal isolates onto petri plate described in step two of preparation of culture for long term storage.

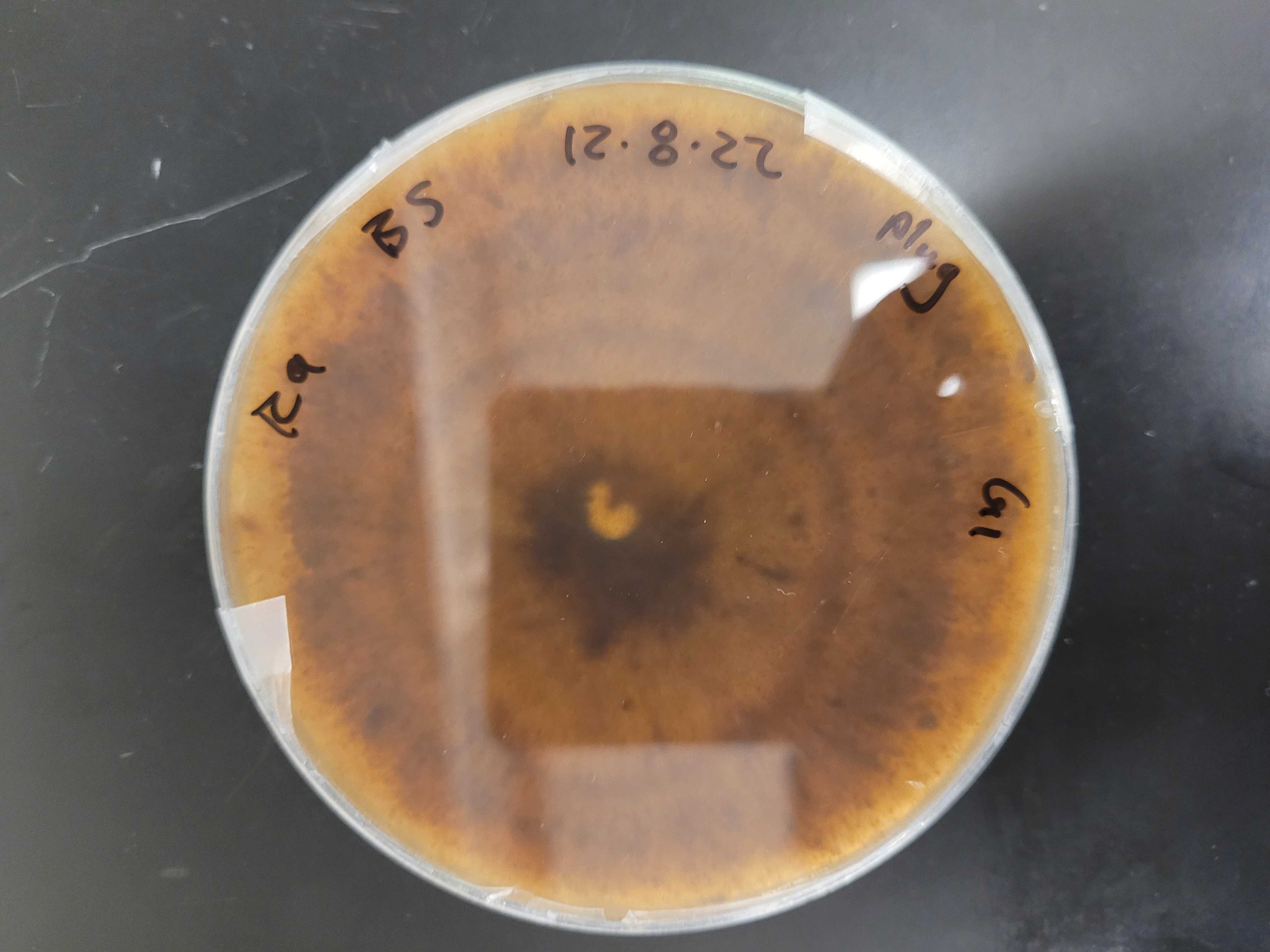

Once the petri plate is fully colonized, in a biological safety cabinet, using aseptic technique, transfer sterile medium colonized with isolate of interest into sterile cryogenic tubes and store at -80°C up to 21-26 months. (Sneh & Adams, 1996)

a. This will be your stock (generation 1, G1) for long term storage. Preparation of working cultures will be derived from this long term storage.

Preparation of working cultures from long term storage

Obtain isolate of interest from long term storage.

Using aseptic technique, in a biological safety cabinet, transfer 5-10 pieces of colonized medium from long term storage onto a petri plate containing 25ml potato dextrose agar and incubate at 25°C with a photoperiod of 16 hours for 4-5 days to fully colonize plate.

a. This will be the first generation colony. (G2)

i. These plates should be kept in incubator at 25°C with a photoperiod of 16 hours for the duration of production.

If production requires more plates, using a sterile core borer, transfer G2 colony core onto a new PDA petri plate containing potato dextrose agar to form next generation (G3).

a. On account of genetic drift, do not exceed past third generation (G3) (Lakshman et al., 2016)

Potato dextrose liquid broth inoculum production

a. Filter of the vented Duocap should be .22 microns.

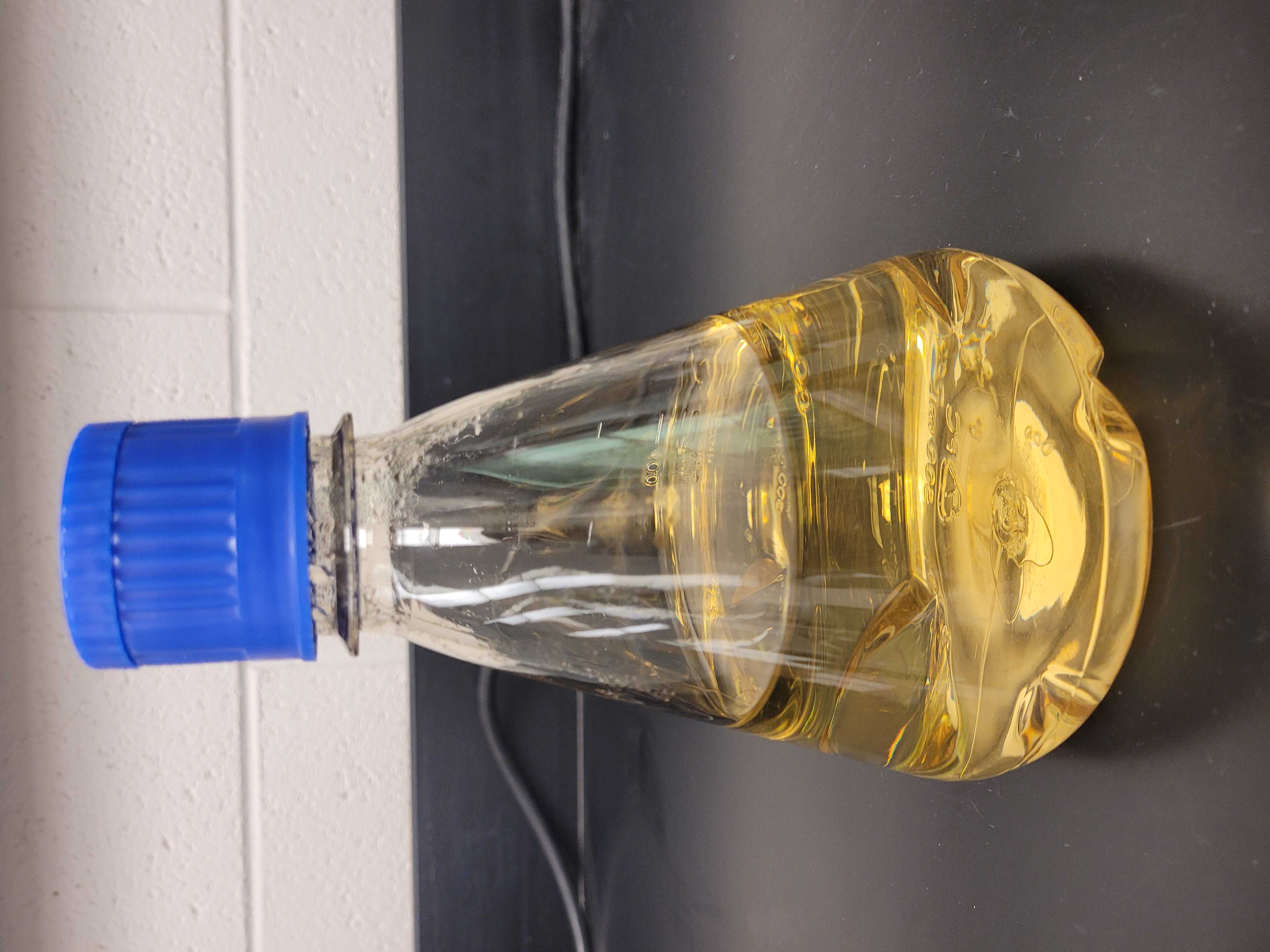

Autoclave flask with PDB at 250°F (121.1°C) for 30 minutes on liquid cycle.

a. Make sure filter cap is loose on the flask with the secondary cap for the filter tightened.

Once cool, using aseptic technique in a biological safety cabinet, inoculate each flask with several (2-4) cores from a fully colonized working culture petri plate.

a. Use a sterile core borer for cores.

Spawn bag production

NANOpure water is water purified using Barnstead/Thermolyne Nanopure lab water system which produces NCCLS, CAP, or ATSM type 1 water with having 18.2 megohm purity with little to no biologicals present.

b. Mix barley and water in bag and let rest horizontally with filter facing up for 1 hour.

Place spawn bags into cotton cloth bags and place them into autoclave pans vertically.

a. Spawn bags are placed into cloth bags in order to not melt plastic spawn bags on metal autoclave pans.

Autoclave spawn bags at 250°F (121.1°C) for 45min sterilization and 15min evacuation on liquid cycle.

a. Repeated two times in order to fully sterilize barley.

Remove spawn bags and set out to cool horizontally with filter facing up until room temperature.

a. Bags should not exceed 24hours of cooling.

a. Let sit for 15min.

Using aseptic technique, in a biological safety cabinet, open sterilized spawn bags and transfer one colonized flask of liquid inoculum into bag.

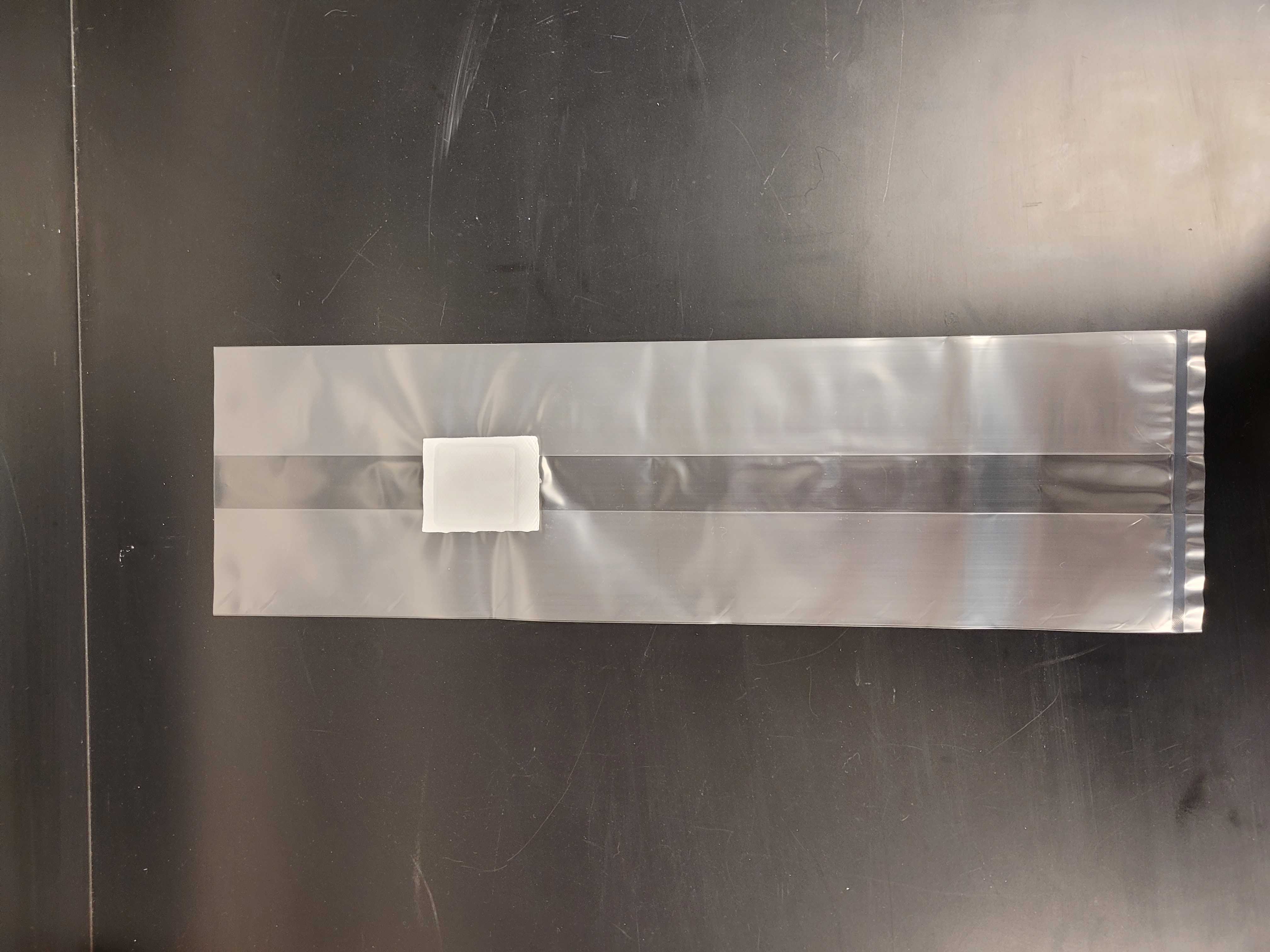

a. Seal spawn bag using impulse poly bag sealer.

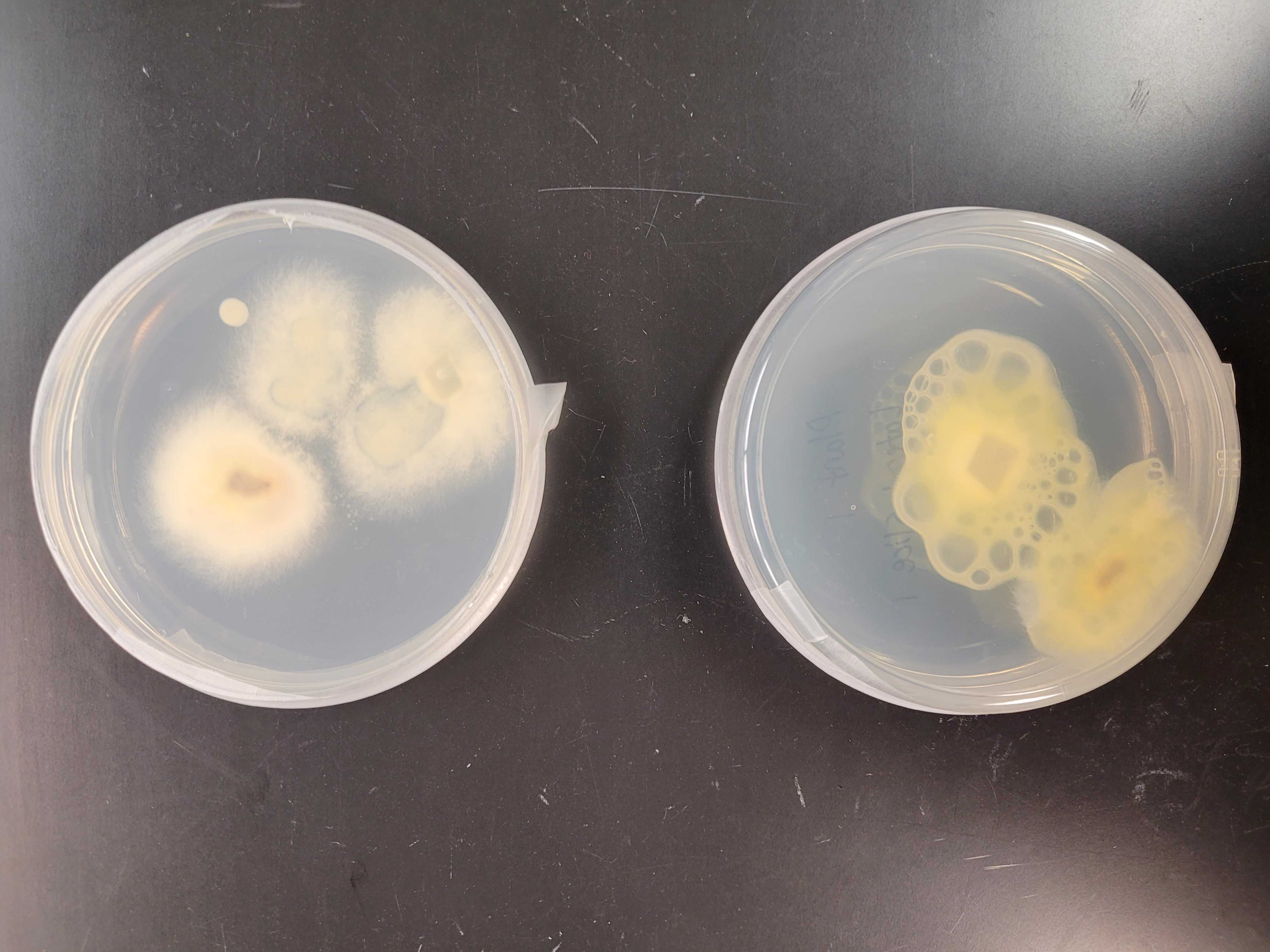

Bacterial contamination of spawn bags show a "soupy" non cohesive barley with an unpleasant "sour" smell.

Fungal contamination of spawn bags show differing colors and possible hyphae that form spores.

R9 should appear only white and cohesive throughout the barley without any fruiting or spore structures.

Contaminated spawn bags should be autoclaved at 121°C for 30 minuets and disposed.